Transformer bushings are crucial components in electrical power systems, serving the vital role of connecting transformers to power lines and other electrical equipment. They act as both insulators and electrical connectors, bridging the gap between transformers and the wider electrical infrastructure and can be categorized into two main types: condenser and non-condenser bushings. Condenser bushings encompass oil-impregnated paper, resin-impregnated paper, and resin-bonded paper insulation types, each offering unique advantages for different voltage levels. Non-condenser bushings include solid core, solid mass homogeneous, and gas-filled types, designed to meet various voltage requirements within the power distribution network. International standards such as IEC 60137 emphasize the importance of selecting the appropriate bushing type, with particular focus on safety considerations – especially for bushings with rated voltage of 66 kV or higher.

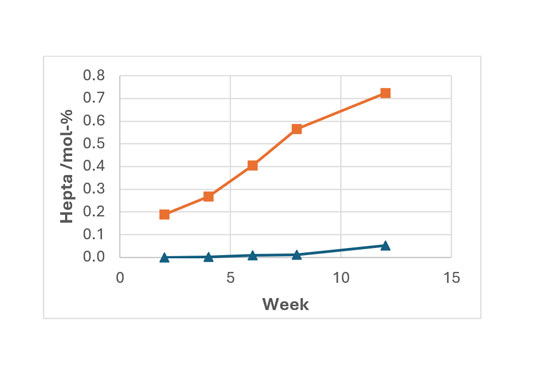

Transformer bushings undergo specific failure patterns during their operational life and issues related to insulation quality decline and center tap components pose significant challenges. Preventive, predictive, and corrective maintenance strategies are therefore crucial to detect and address these issues proactively. Diagnostic methods including capacitance and tangent delta testing, hot collar method, oil testing, thermal imaging and visual inspection all help ensure reliability of transformer bushings. Systematic application of these maintenance practices and adherence to maintenance schedules are vital to minimize risk of failures and ensure reliable power supply.

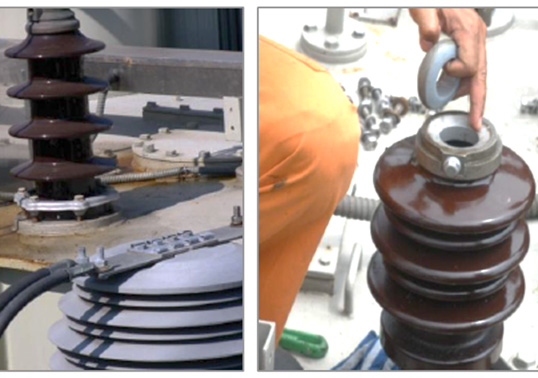

Two common scenarios, for example, illustrate the importance of proper maintenance and diagnostics. Loose bolts on a 500 kV bushing connection can lead to disconnection from the transformer winding, causing increased contact resistance and dissolved gas generation. Monitoring and DGA testing are crucial for identifying and rectifying such issues promptly. Similarly, seal failure can result in oil leakage and moisture ingress, potentially compromising insulation quality. Addressing these promptly is essential to maintain transformer performance and prevent further damage.

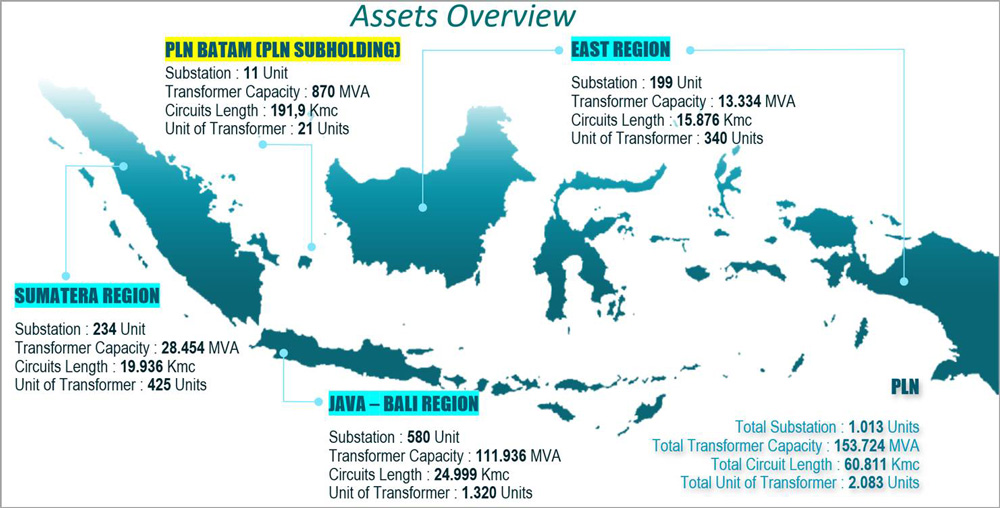

In the case of Indonesia, state-owned Perusahaan Listrik Negara (PLN) manages an inventory of transformers with a cumulative capacity of 153,724 MVA. Approximately 14,000 transformer bushings are essential for ensuring efficient transmission and distribution across voltage levels, including 70 kV, 150 kV, 125 kV and 500 kV. This extensive transformer inventory underscores the critical role bushings play in maintaining reliable power supply.

The journey of effectively managing transformer bushings includes continuous monitoring and periodic inspections to detect any signs of degradation. A proactive approach allows timely corrective measures, minimizing risk of unexpected failures and associated power outages.

Therefore, properly managing the lifecycle of transformer bushings holds significant importance for maintaining reliability. Attention to detail during procurement, vigilant operational monitoring and systematic maintenance practices all contribute to transformer bushing longevity and dependability.

Attend the 2023 INMR WORLD CONGRESS in Bangkok to listen to a valuable presentation by Harry Gumilang of PLN. He will provide comprehensive information regarding bushing lifecycle management and shed light on the most crucial aspects to ensure the reliability of power systems. There will also be lectures by other experts discussing bushing failure scenarios as well as methodologies to detect incipient failures, including:

[inline_ad_block]