Digitalization of power systems is well underway. In this regard, information needed to control, meter, protect and monitor these systems is being collected by numerous sensors that transmit this data into the Cloud. Soon, there will be a situation where most components will be part of the ‘Powernet of Things’. Protocols on data exchange, such as IEC 61850, are already common and even ‘traditional’ equipment, e.g. instrument transformers, can now be hooked up using merging units to fully benefit from the digital opportunities of process buses. Special bypass lanes are reserved for emergency traffic, such as trip signals to circuit breakers or GOOSE messages that cannot be delayed.

In all cases, sensors are at the interface of the physical and digital worlds. Since Cloud data is used to collect information for operation and asset management of power systems, the correct functioning of sensors must be a given. Sensors provide information on the actual status of the system and this information always has to be reliable – especially in abnormal situations from which the system needs to recover in the ‘blink of an eye’. Data analytics and mining make no sense should the source of data, namely the sensors and their hardware channels, not be trustworthy.

These days, sensors are being revolutionized with the advent of embedded software and novel physics-based technology. Traditional electromagnetic instrument transformers, for example, are being replaced by highly compact new generation technologies. These are still based on time-tested principles, named after physicists such as Faraday, Hall and Rogowski, who proposed them decades ago. Their impact is now being exploited by new materials, microelectronics and, to stress yet again, embedded software. Software, after all, can correct imperfections from non-linearities – something that previously was neither possible, nor accepted. Moreover, higher accuracy in measurements is offered. Indeed, this is necessary since power quality is now a bigger issue than in the past while degree of pollution is also higher, with more semi-conductors and non-linear loads entering the stage.

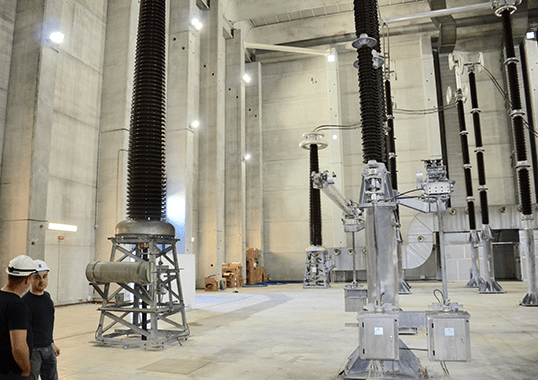

At KEMA Labs, a recent research program saw replacement of certain classical, highly accurate current transformers by optical, low-power units. Test laboratories are a good place to start in this regard since stresses are extreme and requirement for accuracy high. Reliability, by contrast, is a lower priority in a testing environment than within a live power grid. Gaining experience from these pilot efforts, suitable verification methods for such low-power instrument transformers are being development tested. In addition, a program of testing highly accurate, new generation MV energy meters has started. The verification/certification track for such devices, that include embedded software and RF/GPRS data transmission, is a challenge.

The pairing of microelectronics and high voltage is not always a happy union. Classical sensors output strong electrical signals along which electromagnetic disturbance is little more than ‘small noise’. As signal levels get lower, the signal to noise ratio can easily reach unacceptable levels. EMC tests cover such sensitivity but what is often forgotten is that wiring offers a preferred path of guiding unwanted transients inside otherwise well-shielded environments. Therefore, testing intelligent electronic devices (IEDs), together with the primary equipment they manage, is being seen more and more. Such an integral approach is then carried out on complete cubicles or substations under fault or otherwise onerous transients.

Based on recent data assembled at KEMA Labs, about three-quarters of all electronic equipment submitted to a complete type test did not pass all requirements in a single run. While obstacles are often small and overcome through minor modifications, complete redesign is sometimes also needed. Most problems are seen in testing related to accuracy and EMC. In the case of station automation as well as protection and communication equipment, it seems extremely difficult to meet all mechanical challenges (e.g. vibrations) as well as to satisfy all safety requirements while also avoiding ingress of water and dust.

Sensors and their processing equipment, being the supplier of key information, are taking on an ever more prominent role as the source of Big Data. Therefore, it makes sense to verify functionality of sensor systems, progressing steadily not only functionally but also physically to the heart of power.

Continuity of supply is mandatory not only for power but also for data.

René Smeets

KEMA Labs