[inline_ad_block]

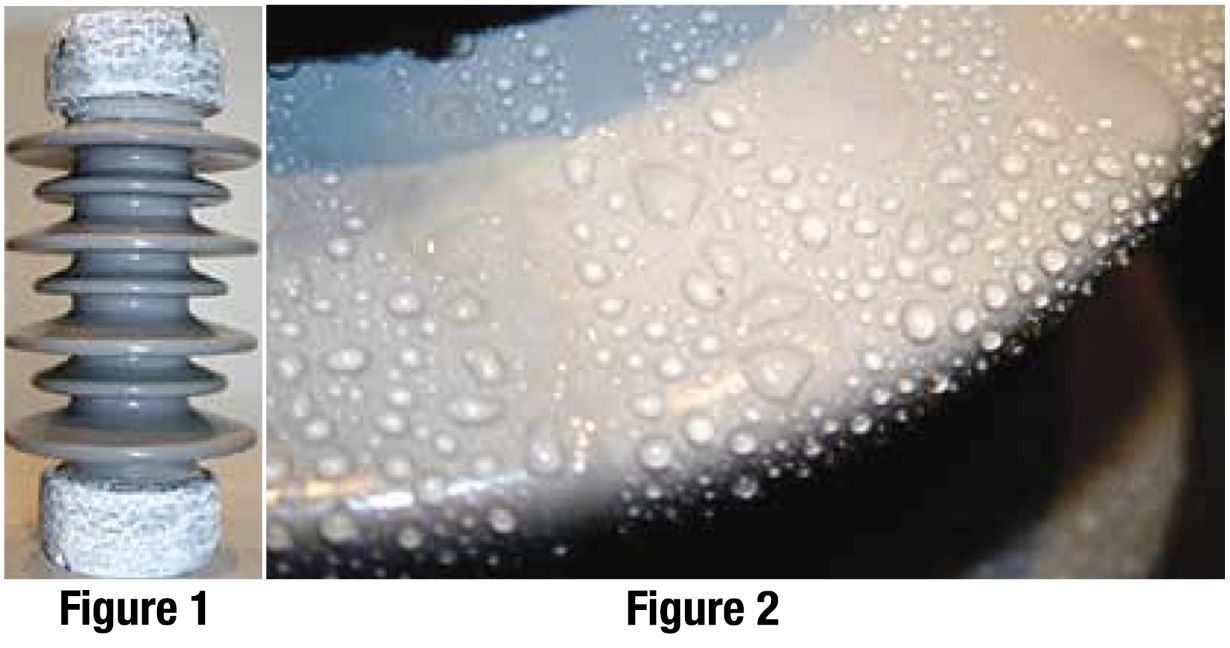

RTV coatings have achieved a permanent place in the diverse group of silicone elastomers used in outdoor power applications. These special materials were originally developed and applied to turn the hydrophilic surface of glazed porcelain or glass into a hydrophobic one and thus improve pollution withstand performance. Most often, these coatings have been applied to electrical apparatus already in service but now exposed to more severe pollution than originally estimated. The material has even been used to extend the service life of deteriorated polymeric housings.

CLICK TO ENLARGE

These days, after decades of successful service experience and continued improvement, room-temperature-curing (RTV) methyl-vinyl-polymer material is no longer being applied only ‘after the fact’ to existing power installations. More and more OEMs have begun to transform virgin ceramic and glass insulators into a new type of product. One can therefore regard the coating as a type of a composite insulating component even though it consists only of a thin water repellent layer added to glass or porcelain materials. Unlike conventional composite insulators, final shape is determined by the structure being coated. While not really a housing material, the coating still functions basically as a ‘property-modifying’ finish with respect to wetting behavior.

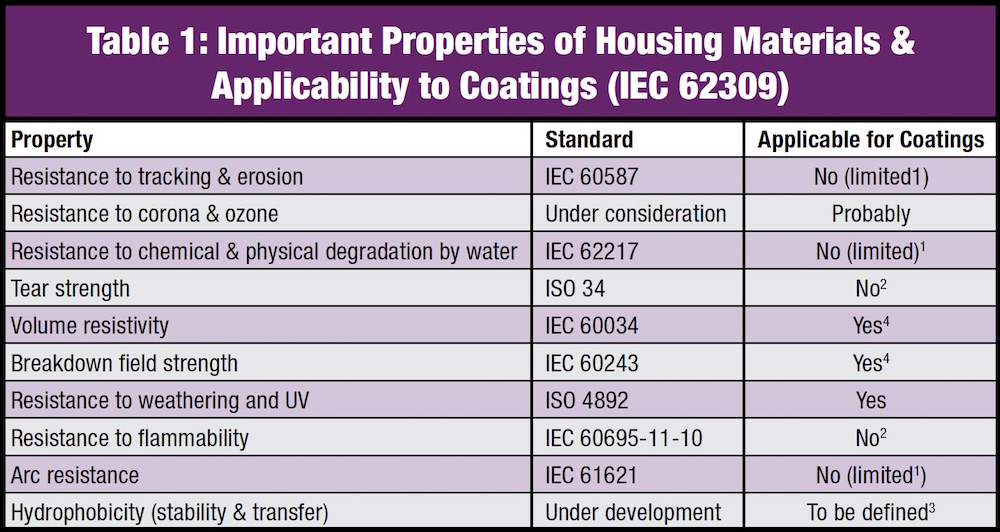

Looking into IEC 62039, TR ‘Selection guide for polymeric materials for outdoor use under HV stress’ it has become clear that coatings are not well covered by the recommendations given for the housing materials of composite insulators. It therefore seems time to add a standard for finishing materials.

Experience shows that coatings do their job as long as the surface along the creepage distance of the coated insulator remains water repellent to at least some extent. Recent salt-fog testing of coated porcelain insulators, for example, showed a fully water repellent surface, even after 1000 h.

CLICK TO ENLARGE

Dr. Jens Lambrecht