This edited past contribution to INMR by Alberto Pigini discussed areas where he foresaw opportunities to add intelligence to insulators.

Several important trends have been driving development of transmission and distribution networks:

1. Increasing demand for electrical energy by developing countries;

2. Shift from fossil fuels to electricity for key end use energy sectors worldwide (e.g. EVs); and

3. Change in the power generation mix toward more de-carbonization along with a rapid increase of renewable energy sources (RES) that are often highly fluctuating and relatively difficult to dispatch.

For example, not long ago the European Union announced plans to generate fully one-fifth of its electricity from renewable energies while some scenarios foresaw an even more radical evolution. An interesting study in this regard was titled ‘100% Renewable Electricity: A Road Map to 2050 for Europe and North Africa’. According to the various organizations that participated, a substantial and rapid de-carbonization of electricity generation will have to take place to limit climate change.

To move towards this goal, one scenario envisaged that fully 100% of electricity generation by 2050 will come from renewable resources, i.e. by integrating wind and hydraulic resources of Europe along with the wind and solar resources of North Africa and possibility using the hydraulic basins of Northern Europe for energy storage. For example, the energy produced at night by wind farms in Denmark or England could be stored as hydraulic energy in Norwegian fjords and used the following day. Such a scenario would require a ‘power network revolution’. Super transmission grids would need reinforcement of current HVAC interconnections between countries and integrated HVDC super grid long distance connections. Together with such transmission systems, new grids have also been foreseen for distribution and connection to decentralized renewable generation sites.

Of course, this is only a possible future scenario. The European power system is still split into separate synchronous grids. Moreover, this transmission system is mostly old, often inefficient and typically heavily congested. In addition, the North African grid is only partially linked with that of Europe. A similar if not greater transmission (and distribution) upgrade is needed as well in the United States. That country’s existing grid is in some respects a ‘relic’ given the relatively minor investments made over the past 50 years.

But things have been changing. One indication is the past initiative in Europe by ‘Friends of the Super-Grid’ proposing a Phase 1 project to connect England, Scotland, Germany and Norway at a cost of some €34 billion – an amount close to that foreseen by the North Sea Countries Offshore Grid Initiative. The estimated investment for a more systematic intervention over the next two decades is on the order of hundreds of billions of Euros in Europe and an order of magnitude higher worldwide (i.e. USD 1.8 trillion based on past IEA estimates).

Such costs and resources make it urgent to make use of the smartest technologies to optimize system exploitation. In other words, these future grids would have to be smart, reliable and cheap, while also integrating new networks with old. While ‘smart grid’ means different things to different people and its definition varies by country and discipline, most agree that it should be more efficient, resilient, strong, reliable, predictable and cost efficient.

The massive capital expenditures expected on smart grids over coming decades will create unparalleled opportunities for manufacturers of advanced materials and insulators. Meeting the many and varied expectations for these new grids will probably also require development of new designs, materials and diagnostics, including:

Smarter Insulator Materials

‘Smarter’, higher-performance insulator materials would contribute to assure the reliability of smart grids, while also reducing costs. Ceramic insulators have already undergone tremendous improvement in quality and consistency, with better manufacturing and development of new designs specifically for contaminated environments. While the history of non-ceramic insulators is far shorter, their development process has been extremely rapid. Present designs, materials, and production methods are ‘generations’ ahead of the original attempts, to the point that today they are considered essentially a mature product and no longer seen as a high-risk alternative to conventional insulators. Superior materials (i.e. super-hydrophobic and environmentally friendly as a result of nanotechnology) may lead to a whole new generation of such insulators, designed and optimized for each service climate and pollution situation.

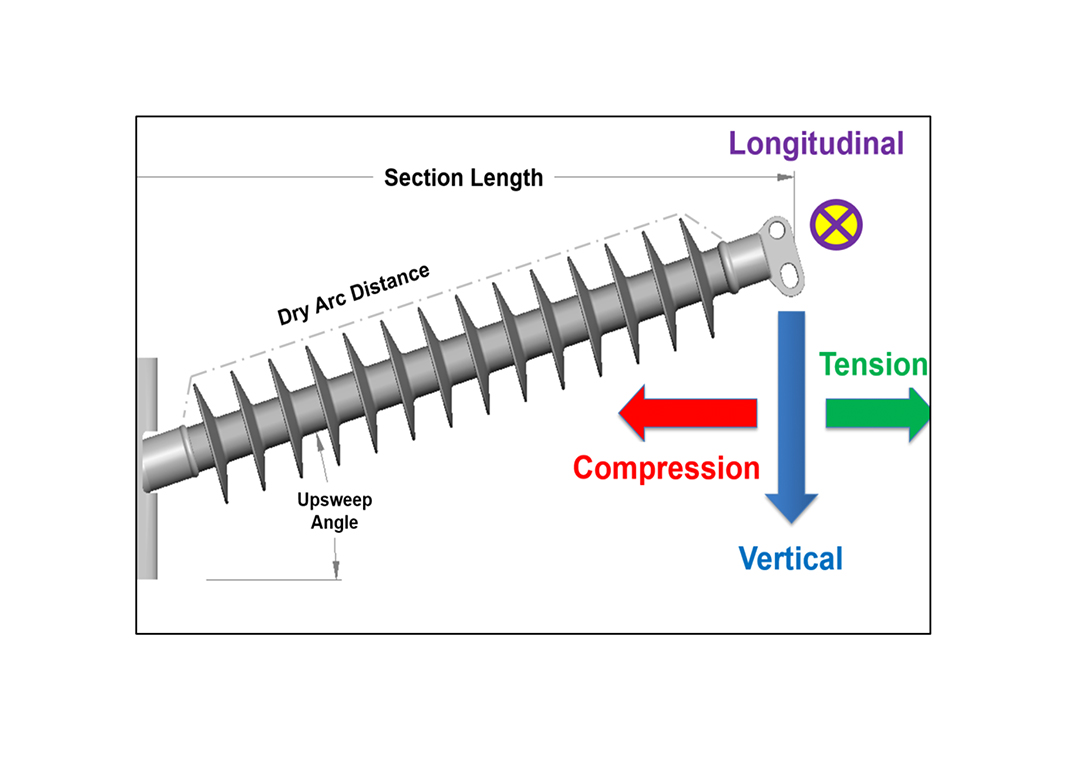

Smarter Insulator Designs & Manufacturing

Availability of ever more sophisticated software will permit more customized insulator designs, both from the mechanical and electrical points of view. For example, the mechanical characteristics of composite housings will be able to be adjusted, case-by-case, to meet seismic and pressure requirements as well as any other mechanical stresses (taking into account the statistical nature of such events). Insulator profiles will be optimized, along with their bulk material, for each application and environment, e.g. selecting profiles to avoid pollution accumulation and improve dielectric performance. In particular, smarter insulators will be developed for DC applications, being that present insulator technology sets a limit on the evolution of UHVDC. Such customized insulators will imply new investments for more flexible and economic manufacturing processes.

Smarter & Less Costly Insulator Diagnostics

On-line condition monitoring of critical assets is one way the electrical insulation industry can contribute to smart grids by avoiding system outages due to insulator failure. Together with new designs of insulators, those units already in service will have to be better ‘controlled’ to improve smart grid reliability. In this regard, improved prediction methods together with less costly off-line as well as on-line monitoring tools will permit operators to know the overall insulation condition of their systems and streamline maintenance costs in the process. Development of better insulator diagnostics will also permit more live line work with guaranteed safety and eliminate the costly shutting down of lines for maintenance.

Smarter Insulation Coordination

Broad use of smart and less costly surge arresters could lead to systematically limiting overvoltages, thereby leading to ever more compact lines and further contributing to optimization of smart grids.

These are some of the ways insulators have the potential to become ‘smarter’.