[inline_ad_block]

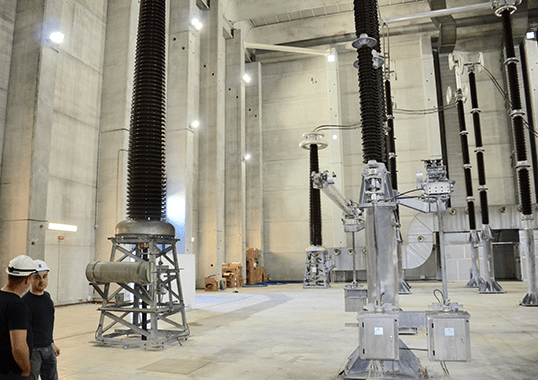

The transmission and distribution sector faces a constant challenge to deliver reliable as well as affordable electrical power. Hence, it is always looking how best to improve on both. Standards-based certification of equipment has traditionally been viewed as the most trusted way to ensure the quality of components that make up the grid and contribute to reliability. But what form should such certification take? And how can components best be assessed against the requirements of relevant standards? Laboratory-based testing has always been and still remains the ‘gold standard’ for equipment certification. Exposing a piece of equipment to realistic conditions that mimic both normal operation and fault situations, yet in a controlled environment, provides the most complete picture of how it will behave in the field.

At the same time, advances in computer technology and modelling algorithms raise the question: can computer simulation eventually replace laboratory testing?

CIGRÉ, for example, explored this question in a past report by Working Group A3.20 that focused on using simulation tools to assess high voltage circuit breakers. In particular, it compared results from simulated and physical dielectric tests on an SF6 breaker with simplified geometry. Independent simulations were carried out by six experts using four commercial software packages. Results were then compared against each other and also against those from physical tests carried out by KEMA Laboratories, acting as independent party. The study found that simulation tools proved excellent at predicting electric fields and resulting stresses inside a breaker chamber under static conditions. However, they were significantly worse at predicting dynamic stresses. In other words, simulation tools accurately determine stress when a component is functioning normally – right up to the point of a failure. However, they cannot reliably predict what will happen once that component has started to fail. They will therefore struggle when it comes to determining withstand capabilities. In fact, withstand predictions in the CIGRÉ report varied by some 40% of the (simulated) average value and also deviated from measured performance by up to another 40%.

Clearly, while simulation is a valuable development tool, it cannot match the accuracy and reliability of physical type tests when assessing performance of high voltage components. In fact, CIGRÉ WG A3.20 concluded: “At present, it is not envisaged that simulation can replace type tests”. This highlights how difficult it is to predict how equipment will behave during operation, particularly under fault conditions. It also has consequences for alternative means to assess high voltage equipment that rely on calculation and explains why physical testing remains the most trusted means of determining quality of grid components. This conclusion is reinforced by another CIGRÉ study that looked at short circuit behaviour of transformers. It was found that, among all large power transformers that failed due to short circuit, one-third had successfully passed design review. But none had undergone a physical short circuit test. Such physical testing can uncover issues that otherwise might remain hidden. Equipment certification based on laboratory testing is the best way to give all stakeholders more confidence in the components that make up a power grid. Yes, such testing is regarded as the high cost option. However, given the potential cost of major failures in energy supply – including repair, fines, liability claims and damage to reputation – it remains the most cost-effective solution to assess quality and performance of grid components.

Jacob Fonteijne

Kema Laboratories