The first silicone cable accessories were developed in the late 1960s and appeared together with introduction of extruded XLPE cables. The main focus at the time was on a design with field-grading and insulating parts in a prefabricated body that allowed easy assembly and helped avoid errors in mounting. The first terminations and joints were still rather massive since the excellent electrical behavior of silicone was not yet fully understood. Still, test results and initial service experience compared to the then state-of-the-art polyurethane and other solutions proved encouraging. The basic concept of a prefabricated silicone elastomer body remained and has since been further refined to the point that today users benefit from a broad portfolio of different silicone elastomers and auxiliary materials for both medium and high voltage cable accessories. This edited 2015 contribution to INMR by Dr. Jens Lambrecht and Dr. Konrad Hindelang of Wacker Chemie in Germany dealt with important aspects of this topic.

Types & Tasks for Cable Accessories

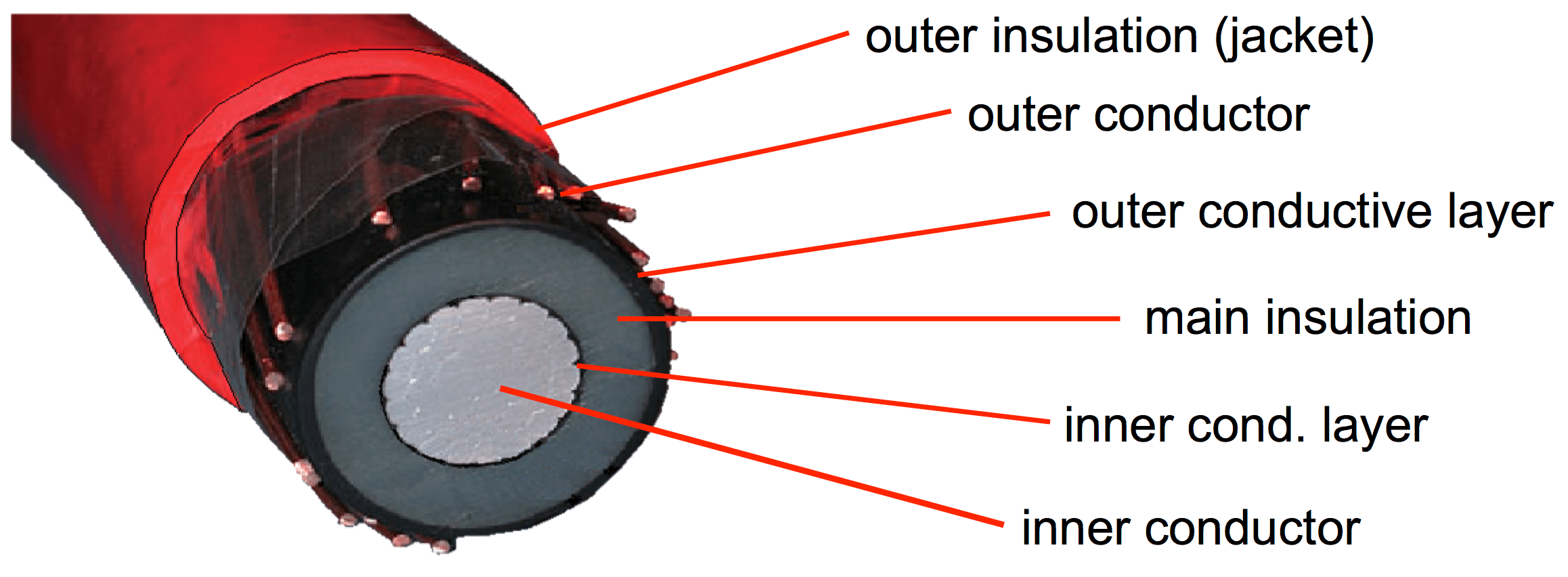

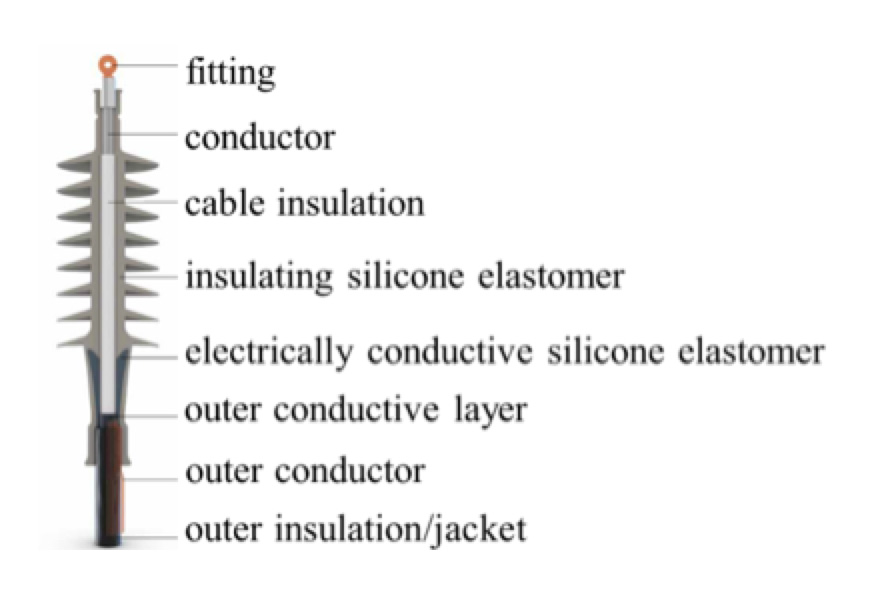

The majority of all power cables are extruded XLPE insulated cables. These consist of a conductor, an inner conductive layer, the main insulation layer, an outer conductive layer, an outer conductor and an outer insulation/jacket.

At places where two cable sections are connected, theses layers have to be re-built in the same way by applying a cable joint or splice. At the cable termination, the layers have to be treated such that they can withstand all resulting electrical and environmental stresses. This is done by mounting a cable termination.

Besides these main cable accessories, there are several combinations and modifications such as connectors and pluggable systems. The main resulting tasks include:

1. Electrical connection;

2. Field grading;

3. Sealing;

4. Withstanding weathering.

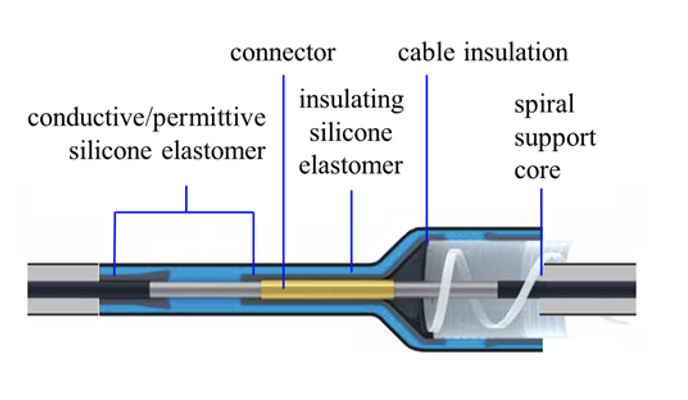

Medium voltage plug-in systems are a good example for the first task. A rather soft silicone elastomer cone is pressed by a metallic spring into the male resin part and provides for a perfect electrically insulated interface. Apart from the low hardness of the silicone elastomer, its high gas permeability is another advantage since any gas trapped in the interface diffuses out shortly after mounting. As mentioned, one of the main goals during early development of silicone accessories was to pre-fabricate a ready-to-use part consisting of all insulating and field grading parts. Fig. 5 shows an example of an older resulting design of joint. All grading parts in this example were made from conductive silicone elastomers. Other solutions applying silicone elastomers with high permittivity are also possible. Silicone elastomers, especially liquid silicone elastomers, have been found to be an ideal material for all necessary step-molding processes since they are low in viscosity and allow for good flow into the mold and towards the triple-points located between mold and pre-inserted conductive parts.

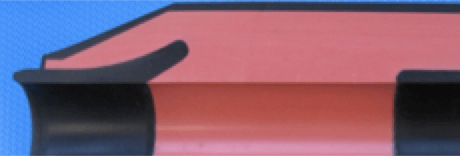

Proper sealing is another important task of a silicone cable accessory. The outstanding mechanical properties of soft silicone elastomers facilitate slip-on mounting while the perfect and lasting ability to shrink to original dimensions, even after long expansion time, allows for cold-shrink technology. Both mounting technologies also benefit from the high gas permeability of silicones. Proper mounting and sealing are supported as well by special silicone pastes available for T&D applications. Pastes can be modified so as to allow easy dismantling even after long time or of a migrating type that disappears from the interface in a short time. Most important in the case of outdoor applications is the general capability of silicone elastomers to withstand weathering. Nevertheless, silicones for these applications are specially modified to ensure lasting stability against weathering stresses as well as the possibility of resulting electrical and erosive stresses during service. An example, shown in Fig. 7, is a termination that provides perfect hydrophobicity. Experience and formulating know-how allow for silicones that can withstand the rather short-term stresses encountered during type tests (e.g. salt fog) as well as long-term stresses during service. It is important to consider pollution affecting outdoor cable accessories. In this regard, the ability of suitable silicone elastomers not only to remain hydrophobic but also to show good hydrophobicity transfer to the pollution layer is important.

Types of Silicone Materials

The principal materials used in silicone cable accessories are silicone elastomers. The early years of their production were characterized by 2-component, low viscosity elastomers designed to cure at low temperatures and parts were mainly cast or vacuum cast. Production output at the time was low compared to the sophisticated technologies available today. Nevertheless, these materials are still available, e.g. for prototyping or for manufacturing of small series of products. State-of-the-art materials for cable accessories are either low hardness, high-consistency silicone rubber (HCR), available as peroxide curing types or as 1- or 2-component addition curing materials for fast and very fast injection molding applications or extrusion respectively. Press molding is not recommended since state-of the-art accessories require a high accuracy of molds. The other option is using liquid silicone rubbers (LSR) that usually come as 1 to 1 two component systems. These materials are now used to manufacture all types of cable accessories. LSRs with 30 … 50 Shore are typically applied for high-throughput injection molding. Modified versions of HCR and LSR with low electrical volume resistivity or high permittivity are also available.

Silicone pastes are also available in a variety of modifications. Extremely soft silicone elastomers, i.e. silicone gels, first saw application in the low voltage area below 1000 V. So-called ‘gel-joints’ allowed proper electrical installation and sealing just by closing shell-like parts pre-filled with soft silicone gel. Thanks to special fillers, new potential applications for silicone gels are becoming evident to manufacturers.

Selected Properties of Silicones for Cable Accessories

There is as yet no standard for definition of general requirements for materials used in cable accessories. IEC 62039TR:2007, Selection guide for polymeric materials for outdoor use under HV stress, covers materials for outdoor cable accessories and defines the following key properties:

• Resistance to tracking and erosion;

• Resistance to corona and ozone;

• Resistance to chemical and physical degradation by water;

• Tear strength;

• Volume resistivity;

• Breakdown field strength;

• Resistance to chemical attack;

• Resistance to weathering and UV;

• Resistance to flammability;

• Arc resistance;

• Glass transition temperature;

• Hydrophobicity

Resistance to tracking and erosion is generally understood to be an important property of all insulating materials for outdoor application and is tested according to IEC 60587 (see Fig. 12). The general minimum requirement according to IEC 62039TR:2007 is a classification of 1A 3.5 but quality silicone elastomers usually withstand the higher classification of 1A 4.5 (Fig. 13) and provide for higher network security.

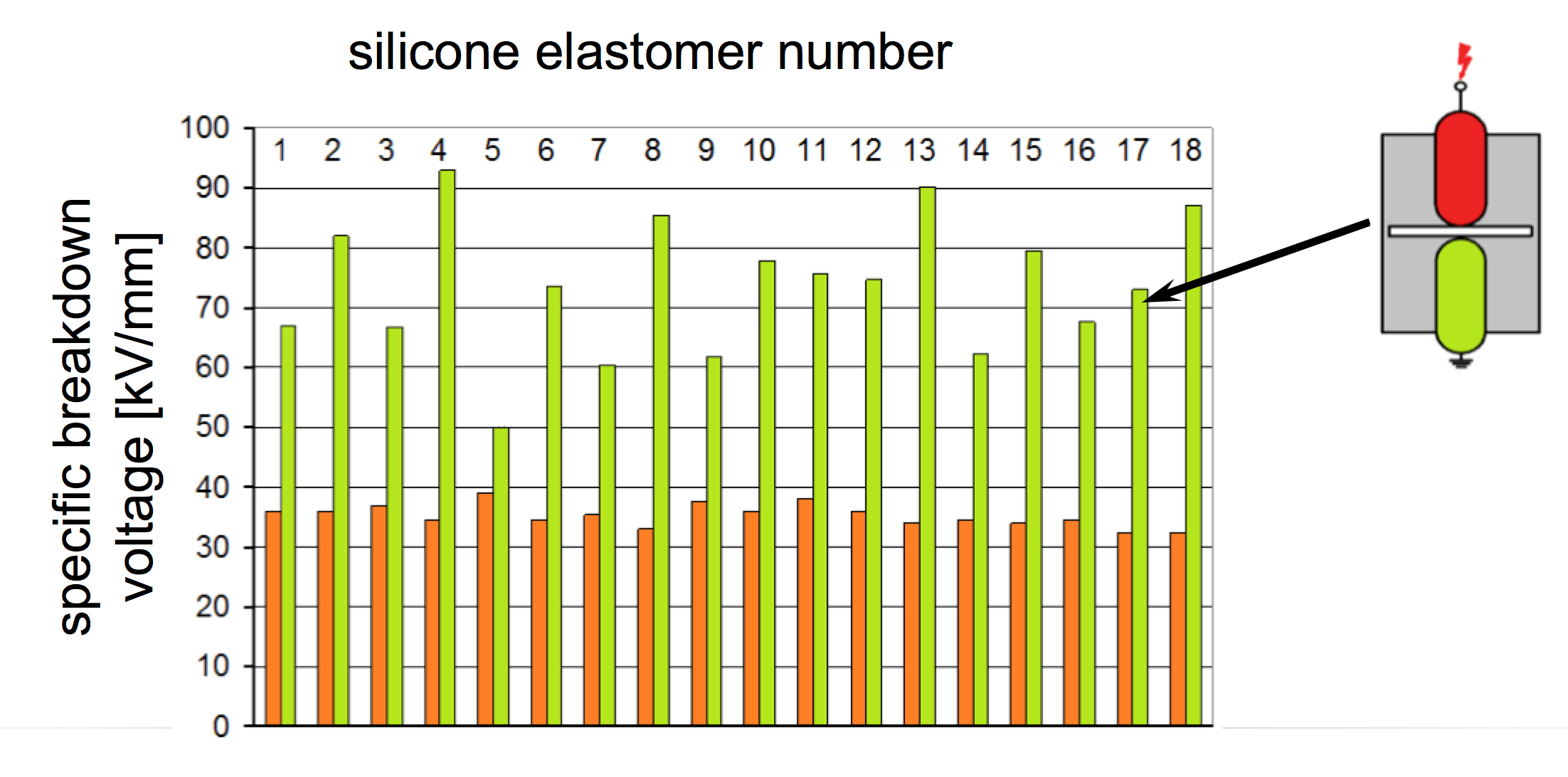

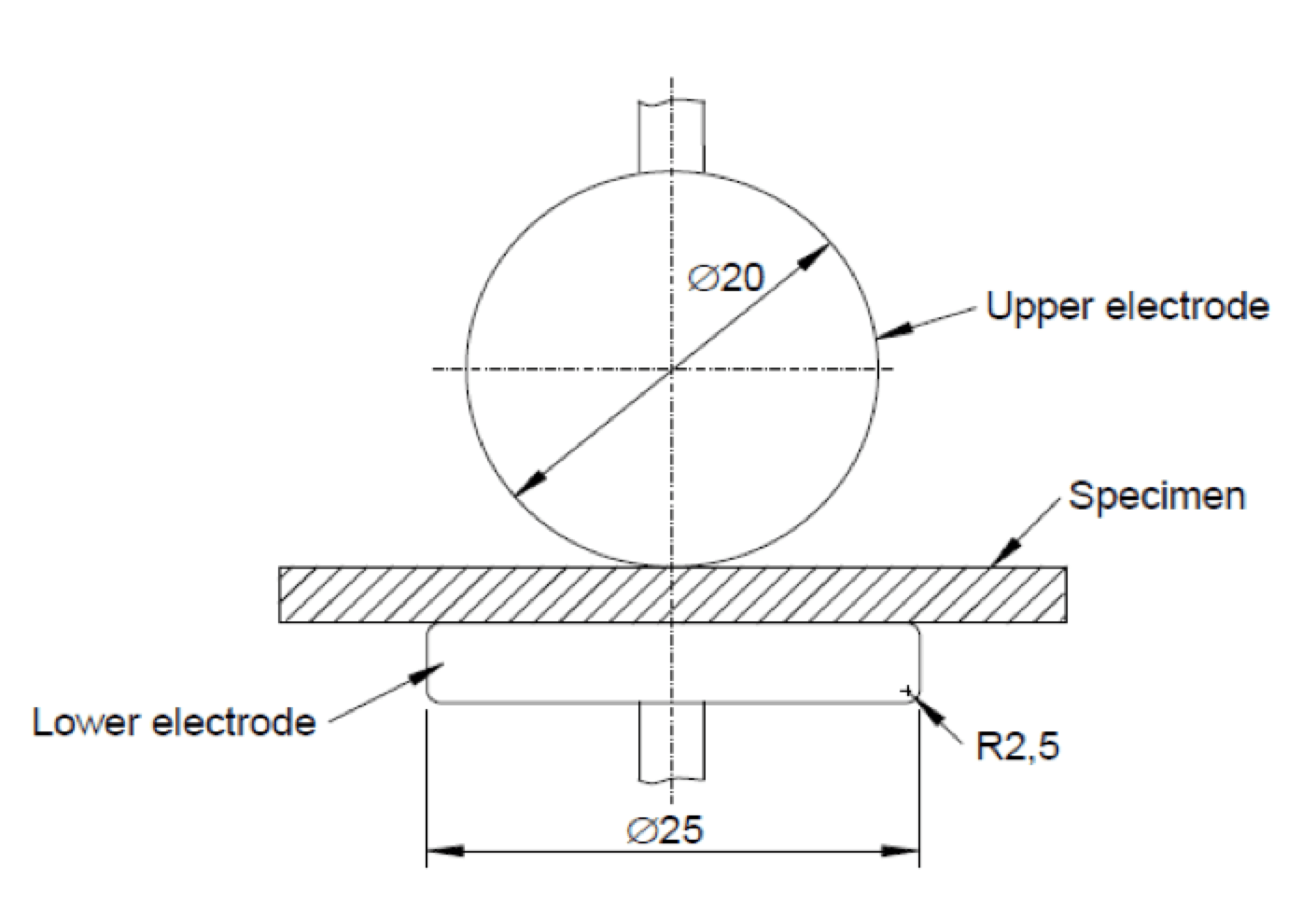

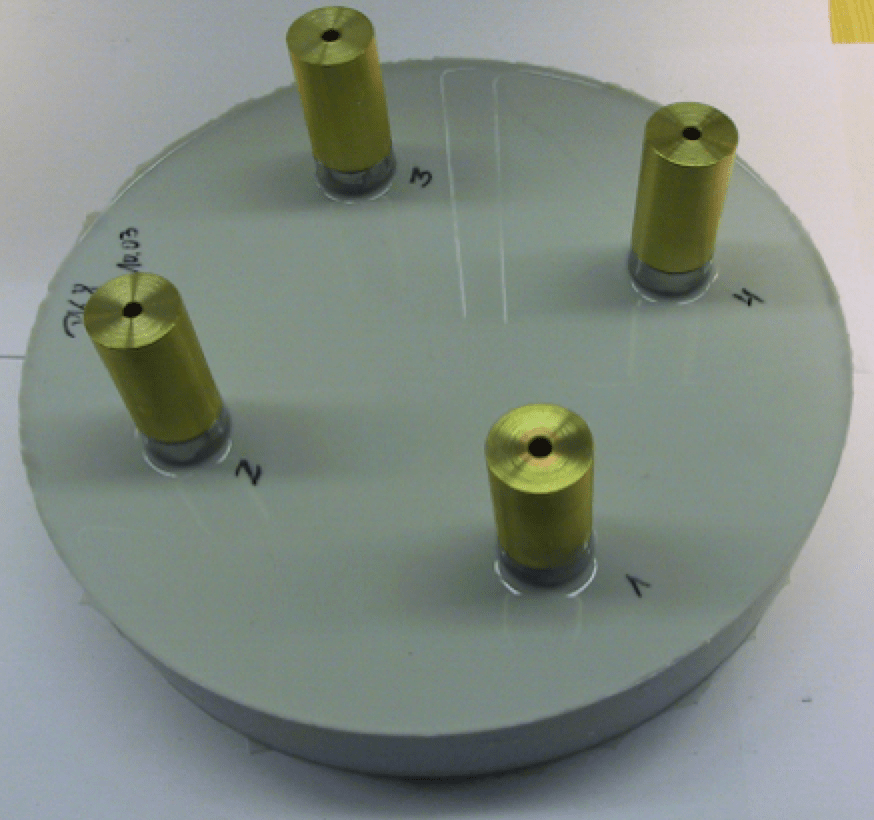

Breakdown field strength is understood to be another important property for such insulating materials. IEC 62039TR:2007 sets the minimum value of 10 kV/mm when measured acc. to IEC 602431-1. It is important to take into consideration, however, that this minimum does not reflect the properties of silicone elastomers. Moreover, the old version of IEC 60243-1 has since been replaced by a new edition, i.e. IEC 60243-1:2013, Electric strength of insulating materials – Test methods – Part 1: Tests at power frequencies which contains a new sub-clause ‘Elastomers’ with the following recommendations:

• Use test specimens of (1.0 ± 0.1) mm thickness;

• Unequal electrodes … shall be used (see Fig. 14);

• In the case of elastomers of low hardness, e.g. silicone rubbers, a suitable casting material shall be used as embedding material or surrounding medium, respectively (see Fig. 15);

Application of the new edition of IEC 60243 leads to measurements that are generally higher compared to the values collected using electrodes in air/fluids (see Fig. 16). It could be claimed that only by applying the proposed electrode arrangement in combination with embedding, can differences in specific breakdown voltage of silicone elastomers be sorted out. Unfortunately, the pure number is of limited interest since it usually neither reflects real electrical field condition in molded parts nor gives information about long-term behavior of materials under stress. Nevertheless, variations in the values show that there are clear differences between different silicone elastomers