Shear Bolt Connector Technology for LV & MV Power Cables by Falk Hardt

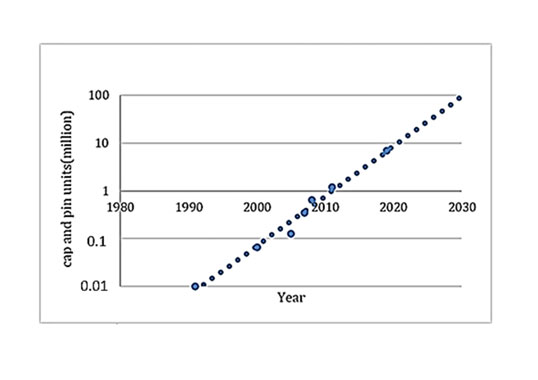

The technology of shear bolt connectors for current transmission has developed quickly. The principle was first introduced in the early 1980s when manufacturers sold the first types of low voltage bolted connectors. The next step was adopting shear bolt technology for use in low voltage cable applications, where required torque moment was a pre-set parameter machined into the bolt. Based on positive field experience, shear bolt connector technology was adapted for use in medium voltage applications as well. But cable accessories up to 42 kV require concentric connector bodies and smooth outer surface, without sheared off bolts standing proud and no sharp edges at the connector and bolts. In the 1990s, connector manufacturers introduced different types of multiple shear bolts, allowing a requested torque moment to a particular cable cross-section while ensuring that bolts shear off flat with the outer circumference of the connector body. At the same time, IEC 601238-1 was established to replace former local standards and set higher requirements in terms of contact ageing. The most important advantage of bolted contacts is that one connector type applies for different cross-sections and conductor materials. This created a user-friendly and reliable connector, simplifying allocation of conductor cross-section to connector. These days, those same principles and connector body design have been adapted and optimized to cover cross-sections of up to 3000 mm² and even for HV/EHV applications. This presentation describes the advantages of shear bolt technology and shows results of an assessment in regard to network reliability and failure modes identified.