This article from 2017, contributed to INMR by arrester expert and co-Convener of TC37 MT4, Jonathan Woodworth, reviewed what users can expect to find in IEC 60099-5. Key elements of this updated standard are identified and explained.

IEC 60099-4 Ed. 3.0 (2014) was the first update of this standard to create the classification IEC Distribution Arresters, which until then had referred to these components as ‘Energy Class 1 Arresters’. Since these arresters are typically used only on medium voltage distribution systems, it was decided to rename them based on application. The former Energy Class system was then rendered obsolete due to certain inadequacies.

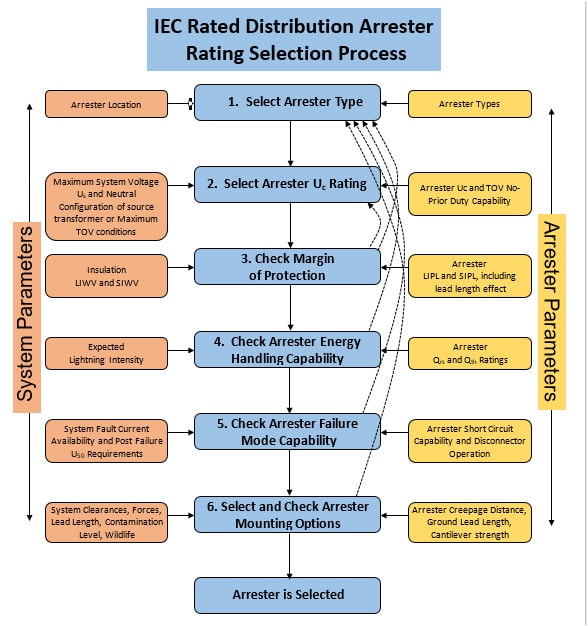

The selection process that will be outlined in the IEC 60099-5 Arrester Application Guide is fairly complex and perhaps more suited for relatively sophisticated station class arresters. For example, it contains more steps than are generally necessary to select a proper rating for a standard distribution arrester. The simplified process discussed here is therefore proposed to assist specifiers of such arresters. It is worth noting that selection of an arrester can be as simple as consulting a table or as complex as having to run a transient model. Either way, the following sections describe all that will be needed.

Step 1: Selecting Arrester Type

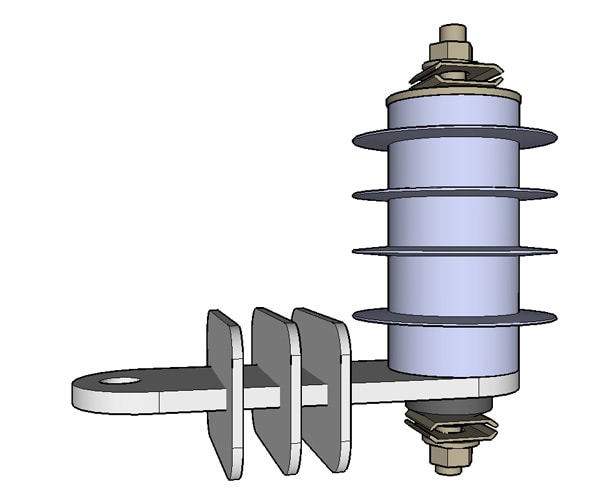

There are several different types of distribution arresters available on the market. If the specific location of the arrester is known, this can provide initial guidance on the proper type to select. For example, if it is to be installed on a distribution pole, a standard overhead arrester (as in Fig. 1) is the best candidate to start the process. If the arrester is intended to serve within a piece of equipment and does not require creepage, an indoor type (as per Fig. 2) may be the more suitable starting point. Nonetheless, the selection process is repetitive and self-correcting and it is possible that later options could require changing what had first been selected. It’s even possible that, based on other requirements, a distribution arrester may not prove suitable and a station class arrester will be required instead.

CLICK TO ENLARGE

CLICK TO ENLARGE

CLICK TO ENLARGE

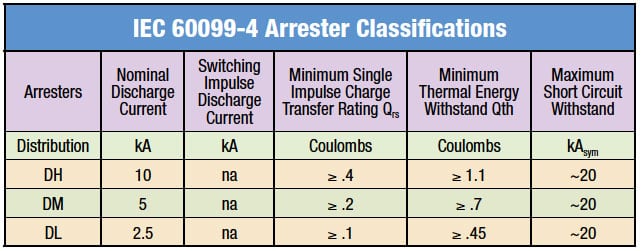

Fig. 4 compares differences between the three distribution arrester classes that represent the options to choose from. These are as follows:

Distribution Heavy (DH)

A typical 10 kA arrester (earlier referred to as a Class 1 arrester) is a common type used especially in areas where lightning ground flash density is ≥4. It is impulsed at 100 kA as part of the Qth rating test found in IEC 60099-4 and therefore sometimes referred to as a ‘100 kA arrester’. This is basically an IEEE Heavy Duty Distribution Arrester.

Distribution Medium (DM)

This is the designation for a 5 kA arrester generally used where lightning ground flash density is <4. As part of the Qth rating test found in IEC 60099-4, this design is impulsed at 65 kA and sometimes referred to as a ‘65 kA arrester’. This rating is similar to an IEEE rated Normal Duty Arrester.

Distribution Light (DL)

This is the distribution arrester with lowest energy capability and used in installations where lighting currents are not likely, e.g. underground cable networks, switchgear in a substation or industrial complex, etc. The Qth rating of this arrester class calls for 40 kA high current impulses.

Although the exact form of any distribution arrester can vary (e.g. separable arresters versus sheath voltage limiters, etc), all nevertheless fall into one of the above classes. Terminal pole or riser pole arresters are normally DH rated, but this is not mandated in any standard. Knowing the type of arrester is necessary so that, once Uc level has been selected, the associated residual voltage can be chosen to calculate margin of protection.

Step 2: Select Uc Rating of Arrester

Step 2a: Select Preliminary Uc

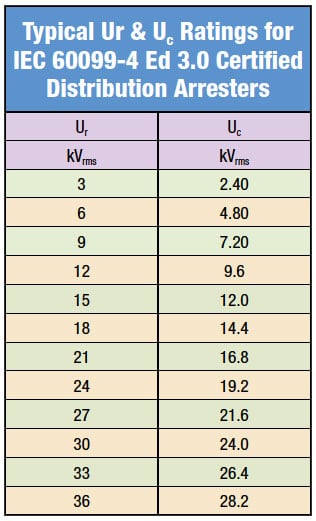

Uc is the Continuous Operating Voltage of an arrester. Since the arrester will be energized through most of its service life, this rating is critical to longevity. However, its selection is also tentative and might need to be changed to meet other requirements. At this point in the selection process, this AC rating is also considered a minimum Uc since it is highly possible that it may need to increase due to Temporary Overvoltage (TOV) requirements.

If historical precedence does not apply, minimum Uc level for the arrester should be equal to or greater than 5% higher than the maximum phase-to-earth voltage the arrester will likely see over its service life. Minimum Uc is: Uc ≥ (Us ÷ √3) x 1.05, where Us is the highest continuous voltage the system will reach during normal operation. The 5% is a safety factor that industry has adopted for this application. In some cases where a better margin of protection is required, it can be reduced with minimal consequences if the maximum system voltage (Us) is well understood.

Step 2b: Select Final Uc Based on Preliminary Uc & No Prior Duty TOV Requirements

The goal of this step is to test the preliminary Uc against the worst-case anticipated temporary overvoltage. Worst-case TOV can be derived either from known system studies or, if these parameters are unknown, worst-case earth fault factors can be used with estimated time durations.

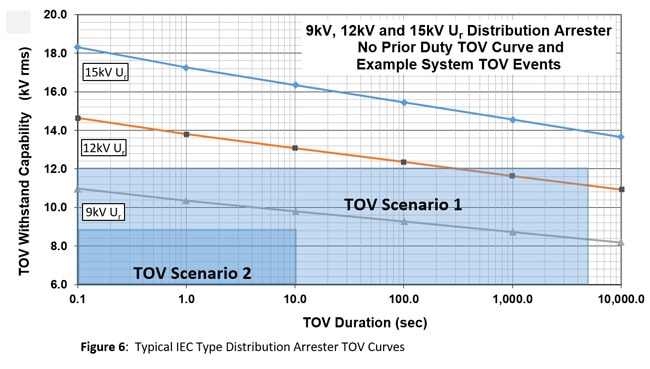

If the worst-case temporary overvoltage scenario is already known from system studies, the longest overvoltage duration and highest potential phase-to-earth voltage can be compared to the arrester’s TOV curve. The arrester TOV curve is usually presented in per unit rated voltage (Ur) or per unit (Uc) and it therefore needs to be converted to actual voltage vs. time. The curve of interest in this calculation is the ‘no prior duty TOV withstand curve’.

To visualize the comparison, overlay a plot of the no prior duty arrester TOV withstand curve and the TOV event using voltage in kVrms for the abscissa (X) and time in seconds for the ordinate (Y). If the TOV event remains completely under the TOV curve (as shown in Scenario 2) of a specific arrester rating, the selected preliminary Uc then becomes the selected Uc. But if any portion of the TOV event crosses over the TOV withstand curve of the preliminarily selected arrester (as per Scenario 1), the next higher Uc rated arrester needs to be chosen.

CLICK TO ENLARGE

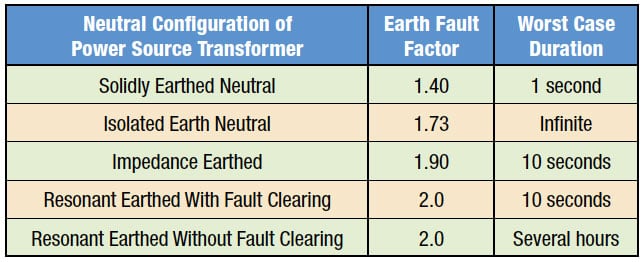

Estimating TOV Event When Duration or Amplitude are Unknown

If the duration and amplitude of a TOV event are not known, the parameters can still be estimated by referring to the neutral configuration of the source transformer. Common configurations and earth fault factors are provided in Fig. 7. If duration of the overvoltage event is unknown, it can also be assumed to be as shown in this Fig.

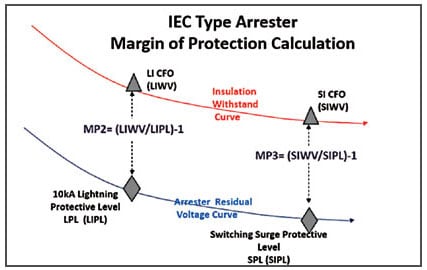

Step 3: Check Margin of Protection

Margin of protection is the difference between Impulse Withstand Voltages of the insulation being protected and the Impulse Protective Levels of the arrester being selected. There are three specific parts to this evaluation:

a. Determine Lightning Impulse Withstand Voltage (LIWV) and Switching Impulse Withstand Voltage (SIWV) of the protected insulation. For transformer or equipment protection, this is a specific level made known by the supplier;

b. Determine arrester lightning and switching protective levels, Upl & Ups, as given by the arrester supplier;

c. Perform the margin calculation and check that it is equal to or greater than the recommended level of 15%.

Margin Calculations

In both cases, the recommended margin for internal non-self-restoring insulation is ≥15%

Fast Front Protective Margin (FFPM)

FFPM = ((LIWV/Upl) -1) x 100 in percent

Slow Front Protective Margin (SFPM)

SFPM = ((SIWV/Ups)-1) x 100 in percent

If both margins are equal to or better than the recommended 15%, the chosen Ur and Uc of the arrester will be adequate. If the margins do not meet this level, a different arrester rating will need to be chosen and Steps 2 and 3 must be repeated.

CLICK TO ENLARGE

CLICK TO ENLARGE

Step 4: Check Energy Handling Capability

There are two types of energy handling capabilities that need to be considered for this step: Repetitive Charge Transfer Rating (Qrs) and Thermal Charge Transfer Rating (Qth). Fig. 4 shows minimum acceptable levels for the three types of distribution arresters. It is necessary to ensure that these charge transfer levels are met for the type of arrester chosen in Step 1. If not, a different arrester type may be needed and it is recommended that Steps 2 and 3 are re-worked.

If the arrester chosen has only been certified to IEC 60099-4 Ed 2.0, it will be labeled a Class 1 or a 5 kA arrester. In such a case, Class 1 is identical to DH arrester and 5 kA arrester is equivalent to DM arrester.

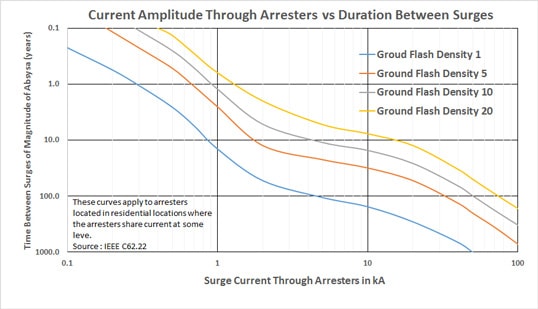

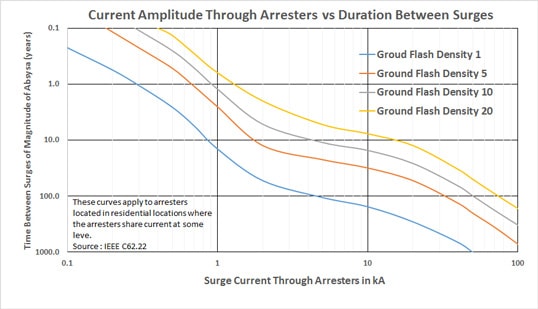

Although the trend worldwide has been to install DH type arresters in all cases, there is no technical evidence that this is necessary. In fact, the opposite may be more correct. For example, IEEE Application Guide C62.22 presents a curve that shows typical currents through arresters based on data collected in the 1980s using thousands of units in locations across the United States. Data shows that lightning currents seldom reach levels that would damage an arrester. Indeed, Fig. 9 reveals that arresters located in ground flash density areas of 5 see a 100 kA surge every 800 years.

This confirms that DH rated arresters are not really necessary in GFD 5 areas.

Step 5: Verify Arrester Failure Mode Capability

If an arrester is overloaded for whatever reason, it tends to become a low resistance. As a result of the change in impedance to ground, it will conduct all available fault current through or around itself to earth until an overcurrent device interrupts the flow. The arrester must not fragment during such a fault-current event.

The short-circuit rating of the arrester is supplied by the manufacturer and verified by tests in IEC 60099-4. This arrester characteristic is referred to as the Rated Short-Circuit Current (Is). The system parameter to compare with Is is the available fault current at arrester locations. This parameter should come from system studies as are usually done to specify over current devices. If the level is not known, the fault current ratings of the system breakers should be used. The arrester’s short-circuit rating (Is) should be equal to or greater than the fault current ratings of the breakers or equal to or greater than the highest potential fault current of the system based on studies.

A second aspect of failure mode of distribution arresters relates to the ground lead disconnector (GLD). The purpose of a GLD is to disconnect the arrester from the circuit should it become overloaded and this is accomplished since the GLD is sensitive to and activated by fault current. However, if an arrester is to be installed on an isolated earth system or an impedance earthed system, it is possible that the GLD may not be activated. Most disconnectors are designed to operate at fault currents as low as 20 amps, but below that level a GLD is not recommended unless already verified to operate at such low currents.

Step 6: Arrester Mounting Options & Other Mechanical Parameters

CLICK TO ENLARGE

This is a ‘catch all’ step for many miscellaneous parameters that do not justify being conducted as a single step in the process. These include ensuring that:

a. arrester creepage distance meets or exceeds system requirements (see Table 1, IEC 60071-2 Ed 3.0 for guidance);

b. arrester cantilever strength meets or exceeds system requirements;

c. arrester mounting fits system requirements;

d. the earth lead of the disconnector cannot cause short-circuit when it swings away from the arrester in the event of overload;

e. recommend minimum clearances of the arrester are met;

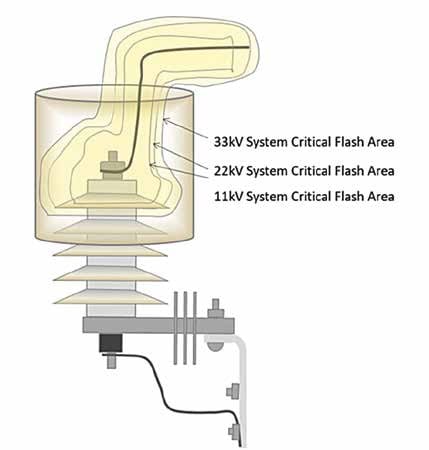

If an arrester is rated below 18 kV, wildlife protectors are typically recommended. Here, it is critical to ensure that the protector is designed to keep wildlife out of the critical arc zone near the top of the arrester (as in Fig. 10). While some arresters are supplied with factory-installed wildlife protectors, it is still worthwhile to investigate if superior designs are available from other sources. If so, these should definitely be considered.

If all arrester parameters meet applicable system parameters, the arrester can be selected with confidence.