The boom in renewable energy, greater use of interconnectors and submarine cables, construction of urban substations in ‘mega-cities’ and growing public opposition to new overhead line projects are all driving increased cable installations worldwide. Underground cable systems are also being adopted to help lower transmission losses and reduce outages by providing continuous power supply. At the same time, electrical utilities are also under pressure to enhance the safety and reliability of their MV and HV networks. However, due to linear installation in vertical and horizontal layouts and relative ease of flame propagation, cables carry risks with potentially catastrophic consequences. Environmental problems can also become significant if large amounts of fire effluents are dispersed.

This edited past contribution to INMR highlighted situations of potential danger as well as tests performed at KEMA Labs/CESI to verify solutions that can improve safety and reduce the consequences and risks from failures of cables and accessories.

Safety is an important factor across the power supply sector due to the risks associated with catastrophic failure of electrical equipment. For example, an internal fault followed by high fault-current and high temperature electric arc can result in a fire that can spread to surrounding equipment and contribute to prolonged outages. Safety becomes an even more important issue when talking about HV and UHV facilities and equipment due to the possibility of unique connections. Indeed, special tests have been introduced to verify safe performance, even under extreme conditions. The safety aspect must therefore always be taken into account during design and also at inception of product development.

Accessories form an integral part of growing power cable networks. Whenever there is a transition to cable systems from overhead lines or busbars, ends are sealed using terminations. Terminations are of different construction depending on whether the application is medium or high voltage. In both cases, however, special care must be taken in regard to pollution withstand since these represent an interface with the service environment. In fact, it is critical never to ‘under evaluate’ the importance of accessories that have consistently been shown to be the relatively weak component in a power cable system. An accessory has to handle the high electrical stresses in the cable insulation and also to cope with the thermo-mechanical forces exerted by cables. Interaction with the cable significantly impacts performance demanded of an accessory.

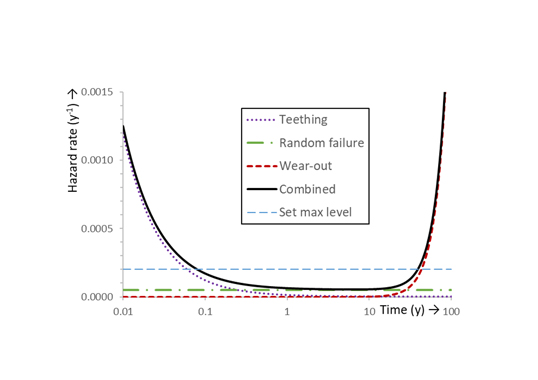

Recently, higher proportions of XLPE cable systems have been introduced into HV networks and more are planned for implementation. The number of relevant cable accessories will therefore increase as well. In a competitive market, improvements to realize lean designs of cables and accessories while also enhancing performance have to be pursued. Yet in spite of ongoing improvements in materials and production processes, failure rate is not decreasing. In fact, surveys suggest that from 20 to 50% of accessory to cable transitions result in failure. Proper selection of ratings and characteristics of medium and high voltage components together with their quality level is important to reduce this probability of failure. However, even then, such events can never be fully disregarded. Therefore, laboratory tests that simulate internal fault are a useful tool to select components that offer safe performance in event of failure and reduce risk of violent explosion and fire ignition.

In Italy, ENEL’s MV network has a length of about 300,000 km. Some 35% of this consists of underground cables, mostly XLPE, EPR and some impregnated lead sheath paper at 15 to 20 kV. Different kinds of joints are also being used including transition joints. In most cases, these cable networks are buried and protected against damage using bent cement tiles or recycled PVC plates. Fire resistant coverings include silica textile, self-expanding resin, intumescent material, heat shrinkable sleeve, ceramic fiber carpet bonded thoroughly to aluminum sheet, sand, etc. However cables can also be laid, especially in large towns, in tunnels, underground passages and so on. In such environments, breakout of fire and its propagation are possible given that air is allowed to circulate. For example, tests on 12/20 kV 240mm2 cable have been performed in the past to gain experience with different protection solutions as well as to highlight the impact of internal arcing and related explosion and/or fire.

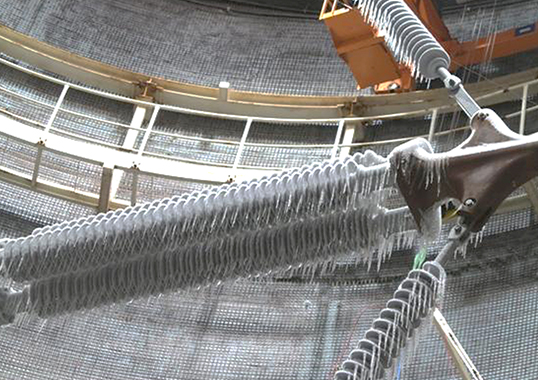

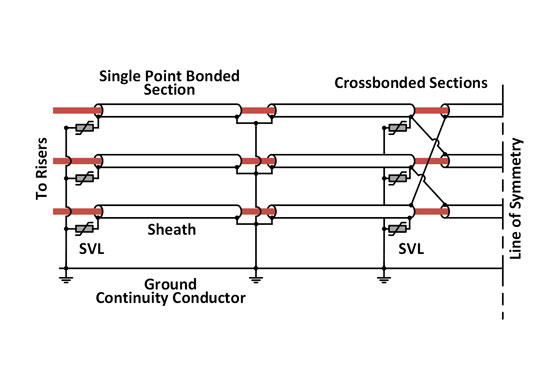

Italian System Operator (TSO) Terna has in recent years also become interested in the behavior of HV underground cable systems with the goal of verifying damage to adjacent cables, fire development and gas emissions. In this regard, tests were performed on full-scale cables (400 kV 1600mm2) laid in a tunnel mock-up where breakdown was intentionally induced by drilling a hole through the insulation and inserting a metallic wire to connect internal conductor to metallic sheathing. The short circuit current following breakdown caused vaporization of this connecting wire and the resulting plasma was sufficient to maintain the electrical arc over the entire period of the short circuit. The main outcome was that, given a short circuit current of 63 kA, a distance of 350 mm was needed for safety in terms of not propagating fire to nearby cables. With a short circuit current of 40 kA, this safety distance was 300 mm. Moreover, given a 63 kV short circuit current, cables buried in a suitable sand backfill to a depth of 1.65 m and protected by a concrete slab showed no significant mechanical effects at the surface due to sand’s capability to absorb impact.

As TSOs search for innovative solutions to further develop their grids, these efforts are boosting demand for components as well as the need to better assess the quality level of the equipment being chosen. This is where testing based certification to relevant standards by independent third parties helps manufacturers reassure customers of the highest quality. In fact, utilities sometimes ask that a specific component undergo and pass more stringent versions of the test standard based on specialized tests that go beyond what is normally required for certification. In recent years, for example, more and more experience has been gained at laboratories such as CESI with internal arc tests on HV cable terminations and bushings performed according to European specifications and standards. The following deals with experience from these types of laboratory simulations of urban layouts that take into account the potential consequences of explosion and fire propagation in tunnels.

Testing Power Arc Events

A sudden power arc fault in a transmission system can lead to severe damage to installed equipment and the environment as well as pose a risk to public safety. In metropolitan areas with underground transmission or distribution systems, such events could also impact staff working on the system or even members of the public who may be near the damage located a few meters below ground. Nor can use of high performance materials, smart equipment, proper installation methods and design criteria fully nullify risk of fault due to some unpredictable event. Hence, this emerging scenario must be investigated and evaluated to verify reliability of these T&D methods, especially underground transmission tunnels where several other public services are typically also located.

These days, related testing activities are assuming greater relevance. Indeed, these kinds of tests, performed on specific layouts and assemblies, contribute to understanding all phenomena related to the fault under any given set of circumstances. Such an approach is the only practical way to assess and demonstrate if a designated solution can properly withstand such rapid and critical events. At the same time, new requirements coming from the marketplace create several technical challenges, both for the testing services provider and the component manufacturer. This is because:

• Applicable international standards or regulations (e.g. Technical Brochure) are still not available for these layouts. Lack of generalized test methods pushes TSOs and other power suppliers to develop their own customized procedures and also to take responsibility for defining all requirements to be met by manufacturers;

• In the absence of applicable international standards, achieving required positive test results, as quoted in any ad hoc technical specification, poses a challenge for manufacturers. Conversely, an international standard could help regulate the performance required by manufacturers. This would guarantee quality and reliability to end users while also avoiding potentially complex testing that is not always consistent with capabilities of third party laboratories;

• Manufacturer and test laboratory both become involved in a process that demands time-consuming resources to prepare and plan all details of testing. For example, third party laboratories have to evaluate requests case-by-case and adopt customized solutions when it comes to issues such as test layout and required measuring systems while also offering cost saving solutions and the flexibility to adapt to last minute deviations due to unexpected events. Moreover, several high-speed cameras (HSCs) are required to have better views and record the event from different directions (i.e. presence of tunnel, fire and smoke development all have to be considered). An HSC recording is always recommended to permit slow motion review and to have a better clarification of the event, e.g. identifying behavior of metal parts, arc, blast and to have a better understanding of particular phenomena. Finally, proper coordination with the customer and fine-tuning the test program are also necessary. In fact, such coordination is key to reducing the number of samples to be tested and enhancing outcomes from the testing procedures.

Below is an example of application of this new testing requirement coming from the market:

Test Layout & Assembly

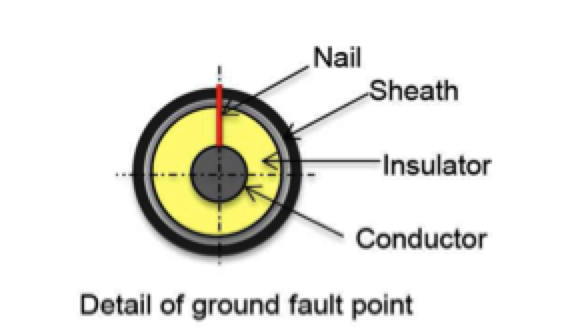

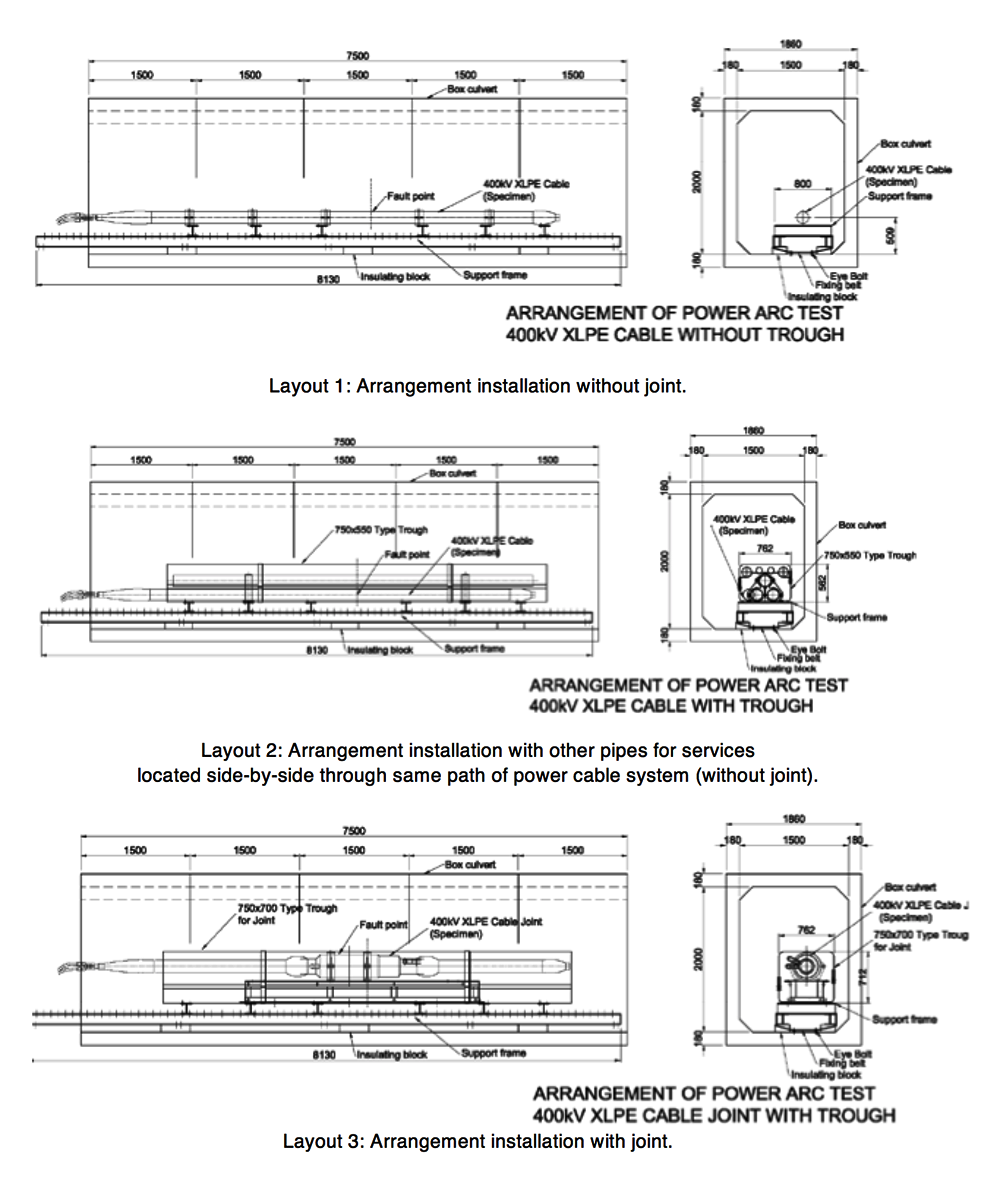

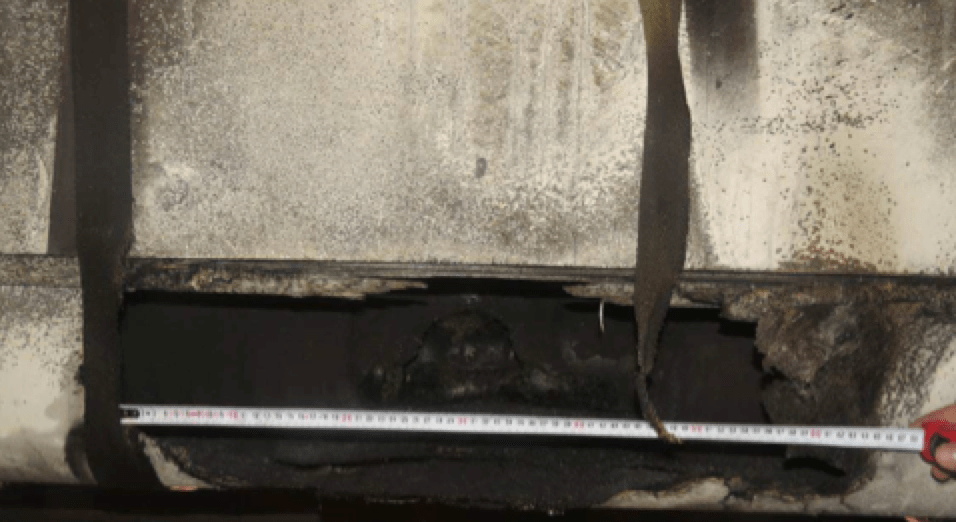

The aim of these tests was to evaluate the effects derived from the energy produced by an arc occurring in several different installation arrangements representative of a 400 kV XLPE (single phase) cable system placed in an urban tunnel. The cable joint portion of the system under test was included in only some of these configurations. Arc initiation was achieved in typical fashion by a fuse nail pre-installed on the specimens under evaluation (see Fig. 1). The entire specimen was wired with Aramid Band having different thicknesses and application methods according to presumed service conditions. Based on customer requests, the full assembly was located in a representative tunnel section of 8 m length and having a breach of 4 m2 (see Fig. 2). Moreover, different layouts were simulated (see Fig. 3). For example, the full assembly was also placed inside a flame retardant FRP (Fiber Reinforced Plastic) cable trough. The main differences among the 6 layouts under consideration included presence of a joint, fire prevention countermeasure adopted and method of application around the sample. This way, test results allowed better comparison and evaluation among the possible solutions being adopted. Both sides of the tunnel were left open to allow recording with high-speed cameras as well as for fire extinguishing at the end of the test.

Evaluation of Arc Energy Effects in Different Cable System Configurations

Power arc tests performed on several cable system configurations and arrangements aimed to verify the effects of arc energy released in the interval of 1 s by a current flow of 63 kA (rms) through the selected arrangement and comparing this against design performance expected. Each test configuration had to be properly realized in advance. For example, the following steps were needed: application of a fuse nail between conductor and metal screen for the fault section; realization of the set-up; application of an FRP fire resistant cable trough and the Aramid/blast wrapped around the specimen. Positioning of mock-up pipelines representative of the services located together with the power cable line completed the arrangement and allowed simulating real service condition under fault. The final part of the pre-test phases was application of sensors inside the tunnel to monitor the main effects of the energy released from the arc. It was important to maintain the same position of sensors along the tunnel during the different tests in order to allow for comparison among the different configurations and methods to suppress damage. In addition, to avoid premature current interruption (i.e. achieving peak current of 2.5 p.u. in the same test sessions and 2.8 p.u. in other cases) properly dimensioned and adequately reinforced connections were needed to the power supply. Withstanding the electrodynamics forces developed during current circulation was taken for granted to avoid unwanted repetition of the test and the need to prepare extra samples.

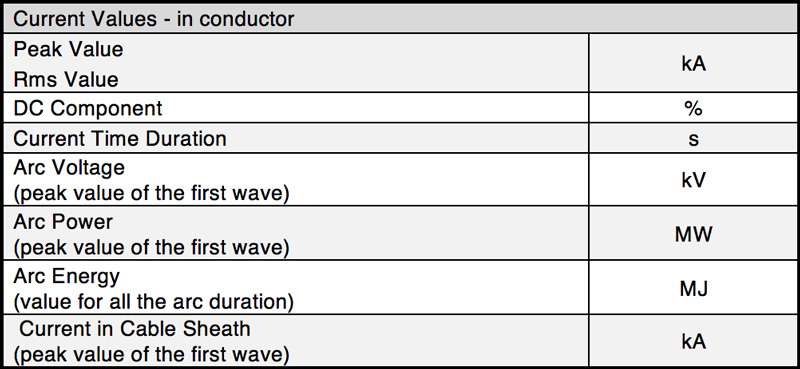

Dedicated instruments and sensors recorded several physical quantities during different test sessions. Measurements of current intensity and arc energy released were integrated with monitoring pressure rise and temperature increase due to arc ignition and fire propagation along the tunnel. Tables 1 and 2 show the physical quantity measurements during a typical test session.

A separate sampling time was requested for temperature measurements. This allowed obtaining details not only during the first second of arc permanence but also during the following minutes of fire development. Such an approach is important to monitor temperatures reached inside the tunnel and their distribution around the fault point. Moreover, a shock wave sensor could also be adopted during test sessions.

During the first second of arc permanence, the temperature and pressure increased quickly, reaching values that have to be seriously taken into account. Temperature values measured at the same sensor positions along the tunnel can be different and depend on the damage suppressor realized during the test configuration being tested. Where a fire prevention solution was not adopted and in the case of the configuration without the installed cable joint, temperature inside the tunnel increased rapidly to above 650°C. Due to the arc, consequent energy release of about 90 MJ together with fire after arc extinguishment continued serious damage the system and propagated flames to other piping installations. This generated further risk to an already critical situation. An elevated pressure wave developed inside the tunnel due to the blast and the values measured were above 10 bar. The visual and acoustic effects of the explosion offered evidence of the importance of such testing to highlight the possible consequences a TSO/utility might have to manage in a real situation (see Fig. 4). Fig. 5 shows sample status around the fault point after the test.

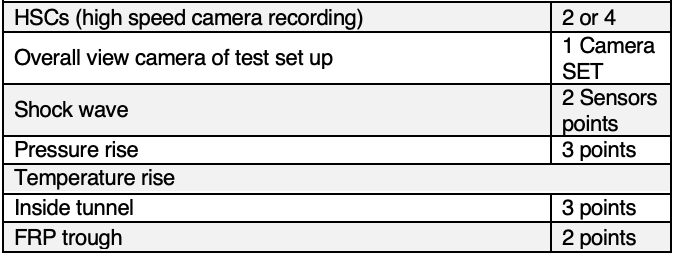

Another cable system configuration, also without installed joint, was tested as well. This time, the system was equipped with a fire prevention countermeasure consisting of application of Aramid Band around the cable and allocated within the cable trough. This solution generated improvement by reducing temperature values measured along the tunnel to around 380°C. Pressure however was of the same order of magnitude as during the previous test configuration. Comparison with another test having the same layout and arrangement but where application of the Aramid Band interval was reduced revealed further reduction in temperature inside the tunnel to below 300°C. The cable trough was also damaged near the fault point (see Figs. 6 and 7).

The greatest adverse impact on the cable system was documented for the assembly that included an installed joint as test results showed the worst outcome of the different fault scenarios. Indeed, when the faulted section was located in the joint (e.g. by a fuse nail as shown in Fig. 8), the amount of energy released was substantially higher than the previous cases and measured value during this test was above 120 MJ. Given that TSOs/utilities are aware that the weakest component in a cable system is the joint, this layout has to be considered as the most essential configuration to be simulated during testing. In such cases, the established arc typically has a longer expansion path. Consequently, a higher amount of energy is released compared to other power arc test layouts.

Other considerations apply to the complex structure of the joint itself, which includes significant amounts of different materials combined together. As a result, a powerful shattering effect is produced due to the arc and, correspondingly, a greater amount of flammable material is ignited. This further contributes to fire propagation. Hence, any countermeasures adopted for damage suppression are exposed to the worst possible event with additional risk of damage to the assembly. Temperature measured inside the tunnel reached over 430°C – higher than for the other test configurations, even when similar countermeasures were adopted. This was due to damage caused to the trough where the cable system is located. Fig. 9 offers evidence of the outcome in this case.

Summary & Conclusions

As a result of market developments, a large amount of new T&D lines and substations will need to be installed and existing capacity will face upgrading. At the same time, recent examples of major outages demand implementation of more stringent regulations in many countries. These situations are pushing utilities to look more and more at testing as a way to demonstrate they operate with due diligence when choosing equipment and technologies. Moreover, construction of urban substations in big cities is another issue along with pressure to reduce footprints of urban substations.

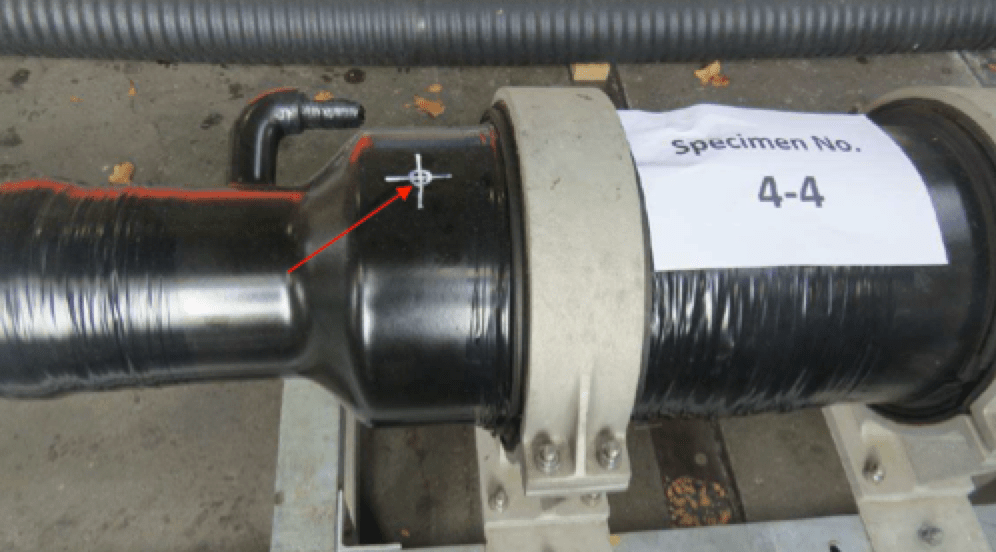

Experience has recently been gained based on internal arc tests on HV cable terminations and bushings performed in the laboratory according to European technical specifications and standards. Fig. 10 illustrates typical results of an internal arc occurring inside power equipment, as observed during internal arc testing on a HV cable termination performed in CESI Milan. The possibility of severe injury and long service interruptions in such critical conditions has to be considered and appropriate solutions adopted.

With reference to underground transmission solutions, testing of different cable system layouts at CESI has demonstrated the possibility to contain the impact from internal arcing. In particular, a notable decrease in temperature distribution inside the tunnel has been demonstrated, even given the same arc energy level. In the case of the fault occurring inside a cable joint, which is typically the most frequent failure in an underground power cable network, an energy increase of about 40% has been recorded. Application of relevant countermeasures such as Aramid Band and flame retardant FRP cable trough can help limit incremental undesirable effects, while also containing fire propagation. Laboratory testing aimed at simulating the effects of accidents in underground T&D networks allows system operators to take the most appropriate countermeasures and reduce associated risks.

References

[1] “10 Year Network Development Plan” ENTSO-E, 2012

[2] U. Vercellotti, A. Sironi “Safety issues in case of internal arc on HV cable terminations, bushings and surge arresters“, INMR World Congress September 2013, Vancouver CANADA

[3] U. Vercellotti, A. Fara, G. Miola “Fire risk analysis on MV cable networks: the behaviour of joints in case of fault“, Jicable 1995, Versailles, FRANCE

[4] O. Bosotti, W. Mosca, B. Cauzillo, L. Lagostena, F. Donazzi, R. Gaspari “Research on the performance of 400 kV extruded cable system under short circuit conditions”, CIGRE’ 1996, Paris, FRANCE