Rod to Housing Adhesion in Composite Insulators – Practical Evaluation in Collaboration with Utilities by Igor Gutman

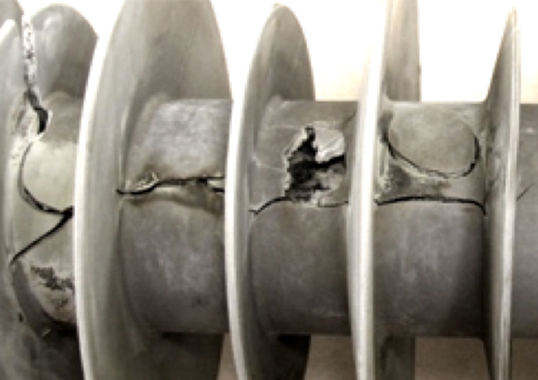

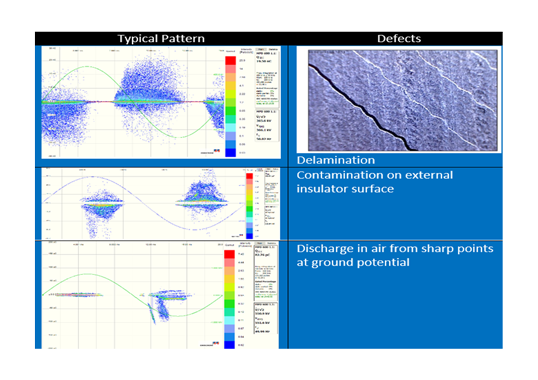

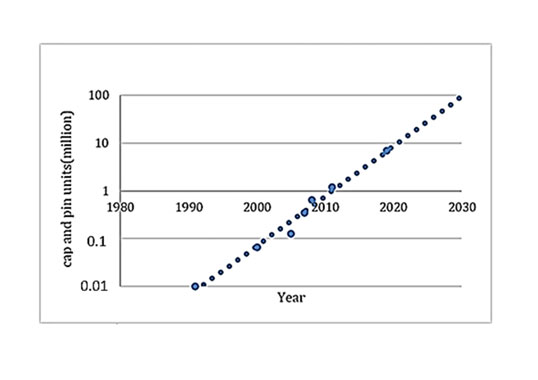

According to industry bodies, worldwide service experience with composite insulators is now considered on par with that of glass cap & pin insulators, with a population in service on overhead lines exceeding 20 million pieces and comprised of insulators of different generations. Initial lack of knowledge in 1st and the 2nd generation insulators from the early 1980s led to service issues that included sealing problems, interface issues between fiberglass rod and housing, flashunder, rod tracking and brittle fracture. These were investigated and overcome in successive generations. However, numerous new suppliers have since entered the market and composite insulators these days can again be of much different quality. For example, forensic investigations have confirmed that the root cause of many service failures is poor adhesion at the key interface between the fiberglass rod and silicone rubber housing. This was clearly revealed from non-standard adhesion tests but not by existing IEC-based tests intended to verify integrity of interfaces. Thus, the issue of quality is considered as not being fully covered by existing standards that may need to be reviewed in the light of this latest reported field experience. This presentation describes the methodology and findings of a research project, sponsored by 9 European TSOs and DSOs, intended to develop a robust, effective test to evaluate level of adhesion.