Long Lake Crossing Marker Ball & Insulator Replacement

by Alison Meredith

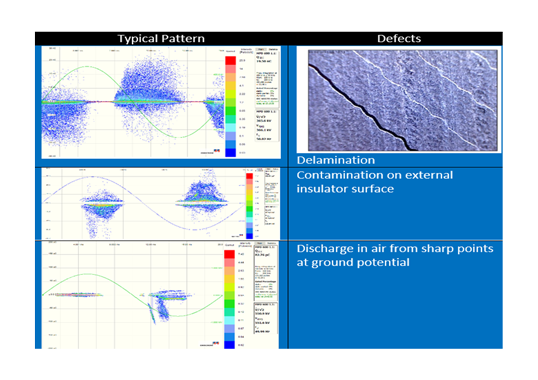

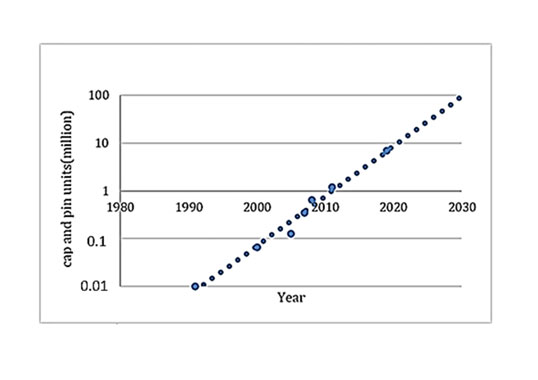

The Kootenay Lake Crossing still ranks among the world’s remarkable transmission line projects. Commissioned in 1952 and designed for 170 kV, it was constructed to supply power to nearby mines. In spite of challenges that came with erecting huge towers in the steep forested terrain, a 3.4 km span across the lake – a record at the time – was deemed preferable to building 120 kilometers of line to go around the lake. Among the project’s notable engineering achievements was the dead insulator arrangement that still carries the typical 75,000 to 79,000 lb. load of the high tensile steel wire used for each phase. Maximum design load for the crossing under wind and winter conditions is 237,000 lbs. Composed of 6 double strings of 18 bells, each assembly contains a total of 216 x 25,000 lb. short-shank, tongue and clevis porcelain bells, connected in a pattern to reinforce strength. One of the challenges has been monitoring the condition of these critical insulator assemblies, where inspection has revealed signs of ongoing cement growth and cracking as well as cases of fracture between pin and hub. There has also been evidence of rotation of the porcelain body inside the cement of the iron cap in some bells. This presentation reviews the challenges and processes during maintenance work to identify and replace damaged insulators and also the marker balls on this long span crossing.