This past May marked a milestone for Energias de Portugal (EDP) as the entire country kept its lights on for four consecutive days using only electricity generated by wind, hydraulic, biomass and solar power. This was apparently a first in Europe, if not the world, in terms of number of consecutive days of production and distribution of ‘clean’ energy alone.

Yet relying more on renewables has been only one of EDP’s major goals in recent years. Another has been responding as quickly as possible to power interruptions from events such as recurring winter storms, frequent fog and interaction with lines by trees and large populations of protected birds – all of which adversely impact reliability. For example, one particularly heavy storm in January 2013 caused outages that affected over a million customers, some for several days.

In summer 2016, INMR Contributor and T&D Insulation Coordination Specialist, Raouf Znaidi, met management and engineering staff at EDP Distribuição (EDPD) to report on how the Portuguese DSO has been dealing with these and other challenges.

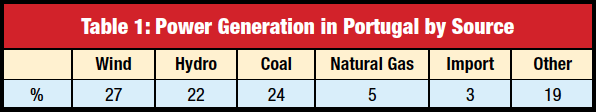

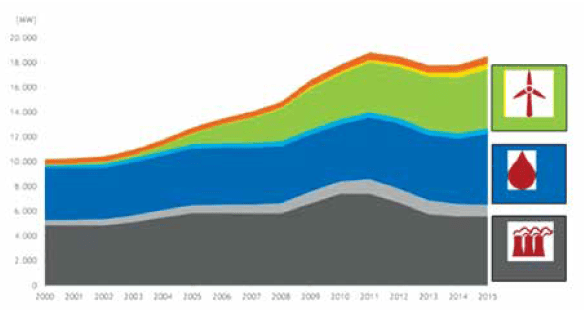

EDP is the largest electricity producer and distributor in Portugal, with a generating capacity of more than 24,000 MW and serving more than 6 million customers. EDPD Executive Board Member, Ângelo Manuel Sarmento, says that Portugal has considerable renewable energy resources of which wind and hydropower are the most cost-effective. Priority has therefore been placed on exploiting the two. Indeed, these sources now account for 33% and 24% respectively of total power generated, ranking EDP among the top ‘clean energy’ suppliers not only in Europe but also in the world.

CLICK TO ENLARGE

CLICK TO ENLARGE

Moreover, when it comes to new investment in green energy, EDP has been closely involved in R&D that relies on floating offshore platform technology, which is claimed to offer significant advantages over wind power solutions based on the seabed. This has positioned the country and its supply partners at the forefront of ‘renewables’ technology. Given these types of initiatives, in 2015 EDP committed to increased green energy generation such that it will exceed 75% of total installed capacity by 2020. This is expected to reduce CO2 emissions from their 2005 baseline level by this same proportion before 2030.

Network Environment

EDPD operates and maintains 81,694 km of lines and cable from 6 kV to 60 kV, with about 80% of the network being overhead. There are 416 substations, 120 switching substations and over 66,000 secondary substations.

Typical Portuguese weather is characterized by an oceanic climate in the north and a Mediterranean climate in the south. For example, average annual rainfall varies from less than 600 mm in southern areas to over 3,200 mm in the northern mountains. In addition, there is high risk of heavy winds, sometimes exceeding 130 km/h. Moreover, western and southern coastlines total nearly 1,000 km and the country the highest proportion of forested area in Europe – some 38% – mostly maritime pine, eucalyptus and protected cork oak.

EDPD’s Maintenance Director reports that one of the greatest operating challenges is ensuring reliability in wooded areas during periods of heavy rain combined with strong wind. The forest soil become highly wetted and bogged down, which increases risk of trees being uprooted – especially species with superficial roots such as pine and eucalyptus that are abundant along 15 kV, 30 kV and 60 kV line corridors.

In addition to dealing with reliability challenges from this difficult service environment, EDPD has also begun developing an Asset Management System based on risk, supported by a corporate project called JUMP, and as described in ISO 55000. These efforts are similar to what was done when being certified for Management of R&D and Innovation in accordance with NP4457 and also for the Environmental Management System as per ISO 14001.

CLICK TO ENLARGE

CLICK TO ENLARGE

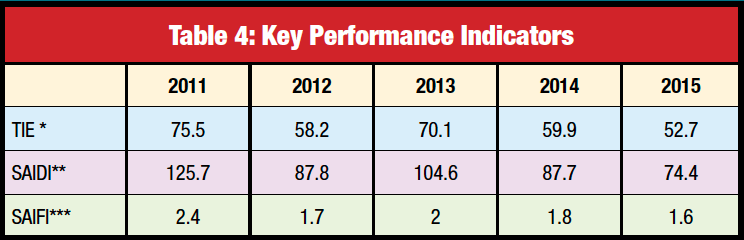

When it comes to key quality of service parameters, these have become the main drivers for all distribution-related activities. For example, a strategic plan has been implemented that sees a combination of technical and organizational initiatives to reduce the number and duration of unplanned outages. This action plan is based largely on different remedial measures but there is now also growing reliance on predictive tools to anticipate potential problems. These are based on analysis of periodic reports issued by ad hoc teams of technical specialists who conduct detailed inspections of lines and substations. The end objective is to constantly improve key performance indicators (KPIs) for the distribution network so as to supply high quality and continuity of service to customers.

Responding to Extreme Storms

Management in EDPD’s HV/MV Substation & Network Maintenance Department explain that their challenge is to accomplish this goal by responding as quickly as possible to any events that impact the network. The most notable recent case was a severe rain and windstorm that battered Portugal in mid-January 2013. Over 3700 structures were damaged on some 40 different HV lines, 470 MV lines and at 20 substations.

This landmark storm affected power delivery to over a million customers – some for up to a week – yet also provided valuable lessons on how better to deal with such events in the future. The ferocity and duration of the storm required mobilizing over 2400 technical staff and contractors to conduct repair work of such scale that some 1100 vehicles and 280 diesel generators were needed. Mobile power plants and substations were also put in place as work progressed to restore supply. Restoration work involved more than 1,270 km of lines and included replacing broken concrete towers with emergency pole and cable kits at a cost exceeding €15 million.

Among the tools that helped re-energize 97% of affected customers within 36 hours were emergency repair kits developed and tested with contractors and suppliers. These kits were among emergency solution options identified during the latest revision to EDP’s Operation Plan & Procedures for Crisis Situations, whose aim is to ensure that resulting service interruptions are kept to a minimum. In fact, EDPD’s response and work in recovery of its network after this storm earned it a special award.

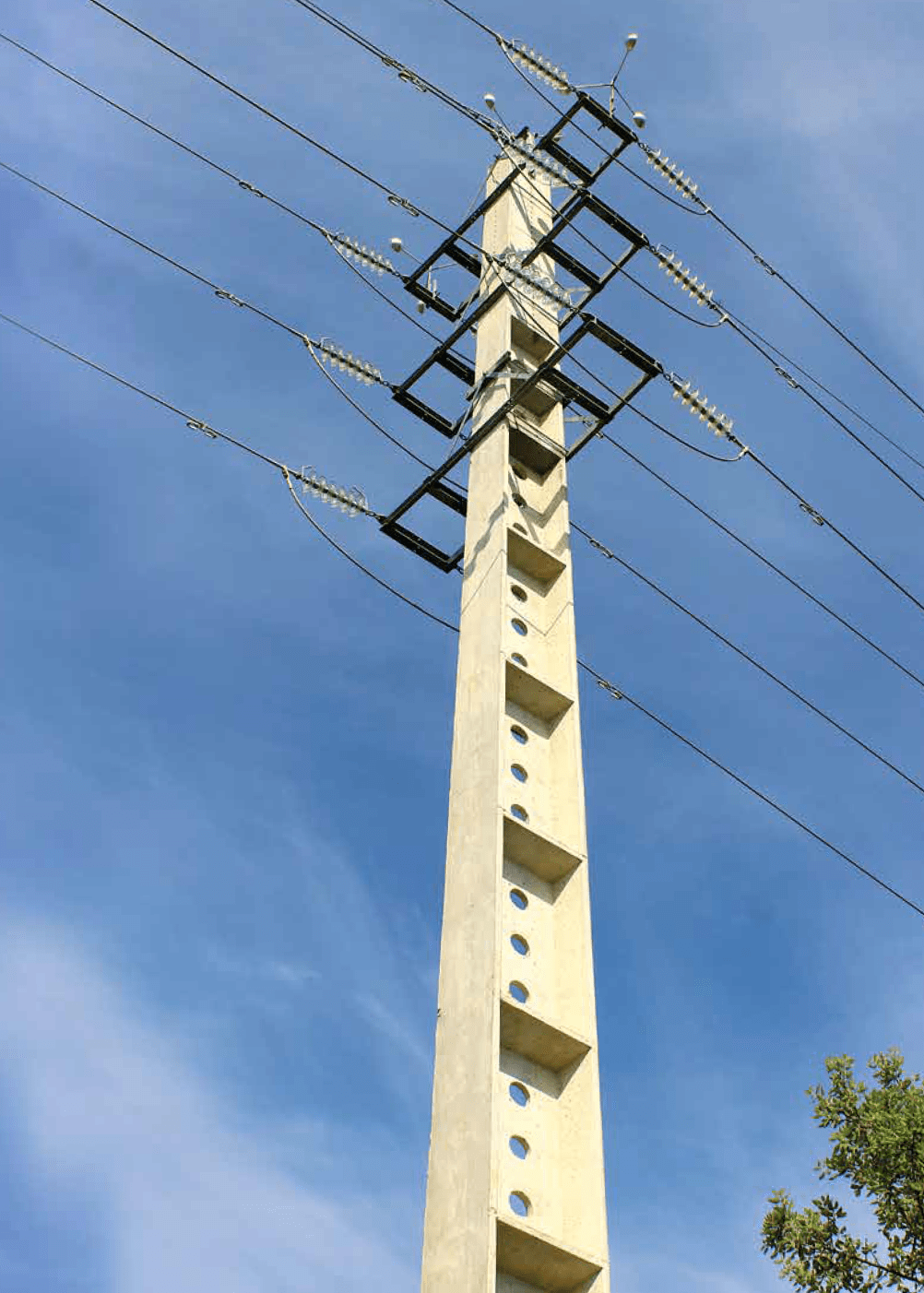

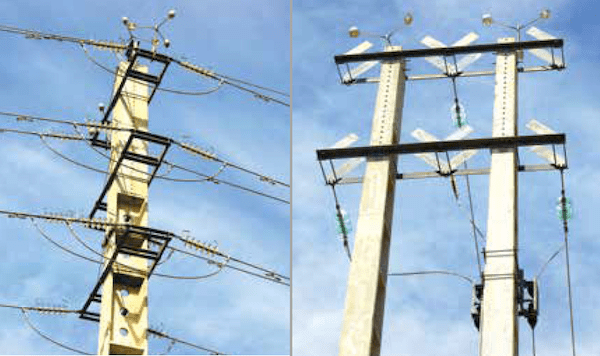

CLICK TO ENLARGE

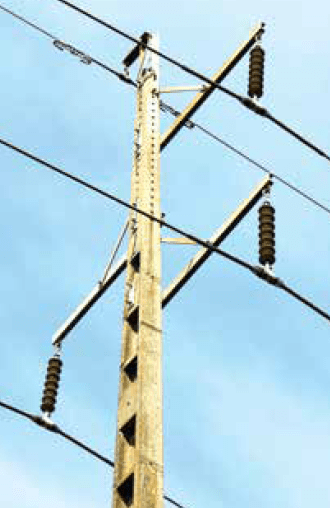

In the case of broken poles, emergency restoration techniques generally include three alternatives: a steel pole solution, a gantry solution and a broken concrete pole top extension (see article on p. 64). All are dedicated to urgent replacement of damaged concrete poles with a suitable special pole that incorporates composite insulators. The emergency cable kit, by contrast, offers a rapid solution to temporarily bypass damaged line sections up to 1000 m using special flexible insulated cables

Dealing with Bird Related Outages

Reports from China, Australia and North Africa suggest that as much as 70 to 80% of all overhead line outages can be directly or indirectly linked to birds. Even though these are almost always characterized by successful re-closure, engineers at EDPD have become concerned by the growing seasonal impact of birds on Portuguese transmission and distribution lines. This has occurred in spite of a variety of countermeasures, including application of special nesting platforms. Bird guard devices of different design have also now been installed not only on towers but also on MV transformers with the hope of significantly reducing outages from accidental contacts. Another goal has been to protect local populations of storks.

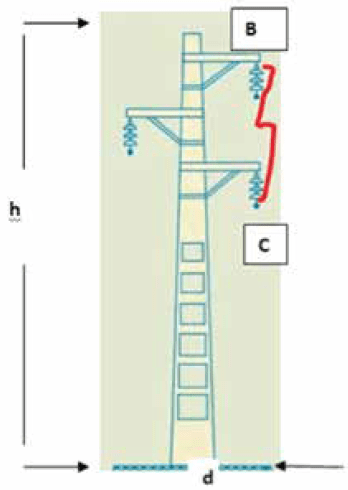

A good example of one successful technical solution is the Montijo Line, which has experienced bird-related outages since as far back as 1990. In co-operation with EPDP’s Technology & Innovation Division, flag type towers on the MV network had their design modified by extending the structural support of phase C. This effectively eliminates risk of accidental contact and short circuit involving insulator strings on B and C due to birds and their highly conductive excrement (see Fig. 2).

CLICK TO ENLARGE

CLICK TO ENLARGE

Service Experience with Insulators

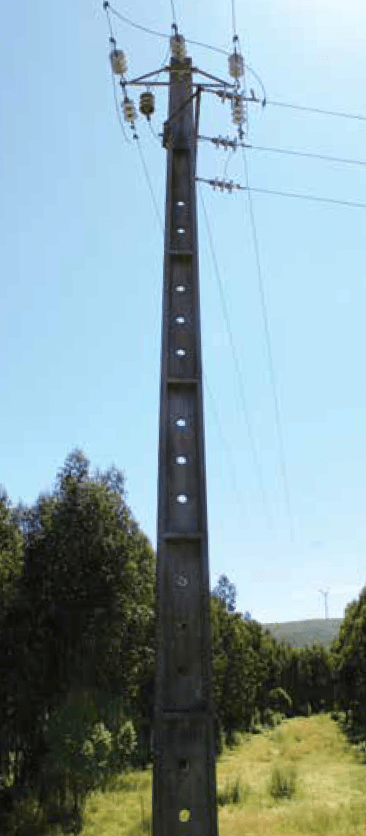

The year 2009 was marked by poor insulator selection and this resulted in serious problems that affected some MV Lines. EDPD’s HV/MV Network Maintenance Team report that locally-made standard profile porcelain cap & pin insulators were specified as first choice but soon abandoned due to frequent puncture as well as mechanical issues with caps.

Given these quality problems, 3 and 6 anti-pollution profile glass discs were used respectively to replace porcelain on 30 kV and 60 kV lines running through contaminated areas less than 5 km from the coast. Equivalent strings of standard glass insulators were also specified for lines further inland.

Even though satisfied with glass insulator performance under both types of service conditions, EDPD nevertheless began co-operating with a manufacturer of silicone composite insulators to assess comparative performance. This trial program has covered insulation on several kilometers of 60 kV line in the south as well as special application of these insulators either as line posts or as spacers on 15 kV and 30 kV poles. Here, the goal was to avoid risk of swinging and accidental contact between braced conductor and ground.

Polymeric-Housed Surge Arresters

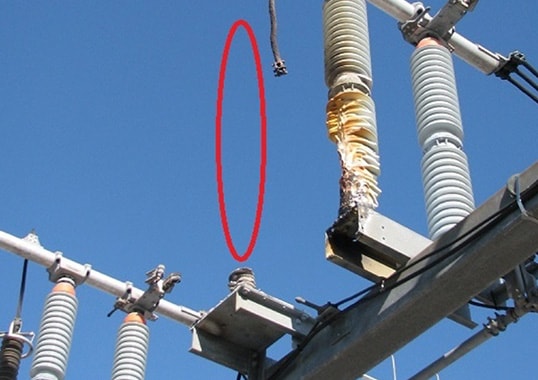

Moisture ingress and external flashover are widely regarded as among the most frequent reasons behind degradation and failure of surge arresters. The leading causes of the latter are overvoltage, contact with birds and severe pollution in conjunction with fog or other wetting events. This was probably the case, for example, in the area south of Lisbon where several failed polymeric-housed arresters, whose disconnector activated or whose zinc oxide blocks became carbonized, have recently been removed for assessment.

CLICK TO ENLARGE

According to the HV/MV Maintenance Team, the source of these failures has yet to be firmly established and failed arresters have therefore been sent to the high voltage laboratory at Labelec for forensic analysis and investigation. They are especially anxious to learn if such failures are due to bad design and manufacturing or more the result of the challenging service conditions such as persistent fog, even during summer months. At times, fog in southern coastal areas can be so thick as to reduce visibility to only a few meters. While ongoing policy in the south is to replace porcelain disc insulators with glass, there is growing preference to return to the porcelain-housed arresters that performed well in the past.

CLICK TO ENLARGE

CLICK TO ENLARGE

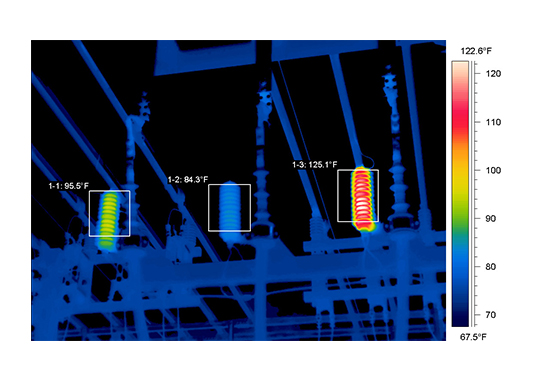

Pilot Experience with RTV Coatings

EDPD initiated a pilot project in 2013/14 involving application of RTV silicone coatings on MV cable terminations and disconnectors with porcelain insulators. Staff in the Substation Maintenance Team report that the coating was applied using a gun spray technique under supervision of the supplier. Since that time, there has been significant improvement in insulation at this substation and at secondary substations, with no further corona activity or noise in spite of high humidity and frequent morning fog.

Vegetation Management in Line Corridors

Among the foremost challenges faced by EDPD is how best to manage protection of flora and fauna (since cork oaks and storks are both protected under Portuguese law) while also ensuring the highest quality and continuity of service to customers. In this regard, resolving problems of rapid growth of forested areas has required a different approach to that used in dealing with wildlife.

CLICK TO ENLARGE

For example, HV and MV lines, especially those running through forested corridors with protected species of tree, suffer from frequent contact with branches, leading to temporary outages of less than 3 minutes. Moreover, heavy windstorms often uproot trees, which collapse and can lead to line drops with much longer service interruption time and required restoration work.

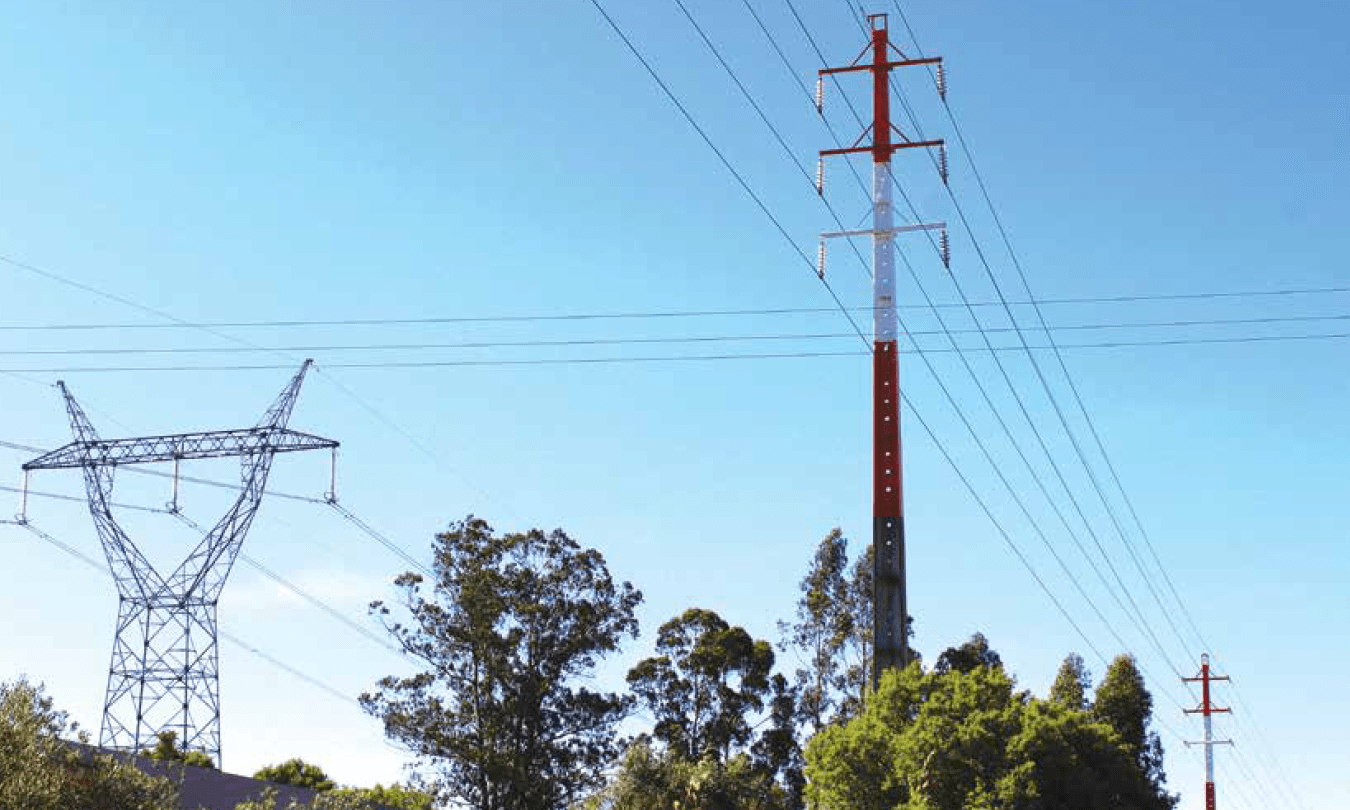

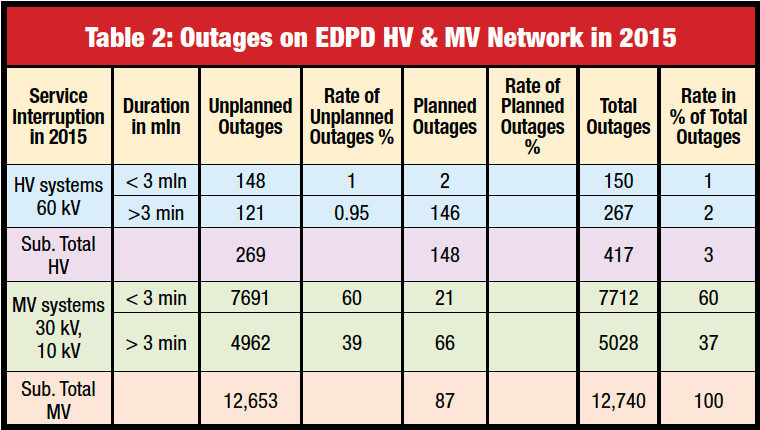

To deal with these types of operating concerns, countermeasures now include use of taller towers (i.e. 22 and 42 m respectively for 30 kV & 60 kV) as well as a strictly observed vegetation management program performed throughout the year by teams of specialists. This involves extensive branch pruning to keep forests in the range of 15 to 25 meters from the corridors of 30 kV and 60 kV lines – considered sufficient to avoid accidental contact and far enough away to prevent risk of fire. Still, in spite of notable improvement in system performance over recent years, Table 2 shows that more than 7,600 accidental short-term outages (i.e. 3 minutes or less) were experienced on MV overhead lines in 2015. Among outages experienced on both the HV and MV systems, most could be attributed to accidental contact of lines with tree branches and interaction with birds.

CLICK TO ENLARGE

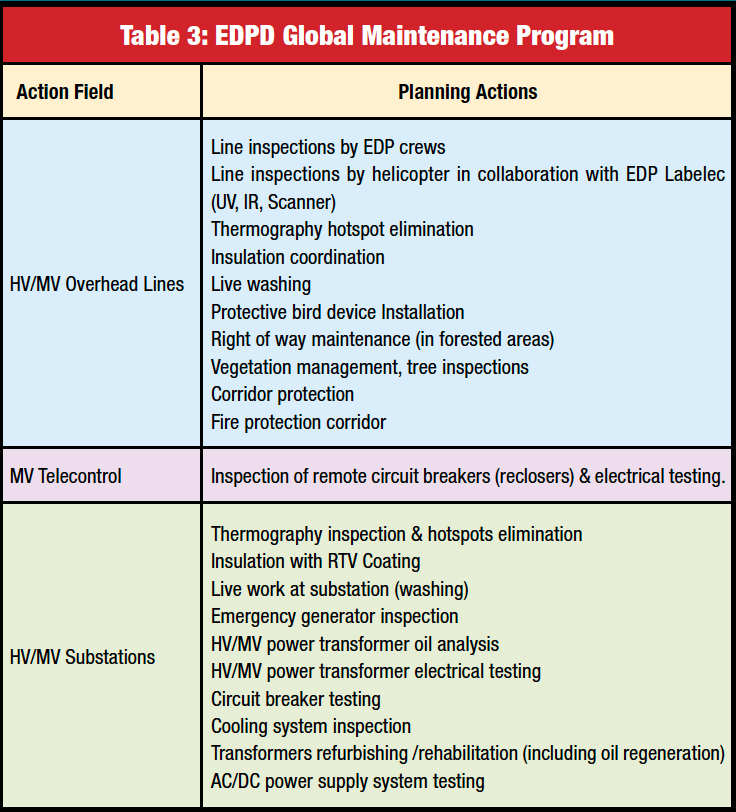

Operating & Maintenance Strategy

To help meet target performance indicators, HV/MV Substation & Network Maintenance managers explain that EDPD relies heavily on a rigorous maintenance program for lines and substations. This includes inspection by helicopter and, more recently, using drones and is done in collaboration with experts at EDP Labelec who help analyze findings. At the time of the visit by INMR, for example, a specialized line maintenance team, supervised by a specialist engineer in the MV Telecontrol Unit, were in the process of systematic maintenance of reclosers used on MV systems. Carrying out specialized maintenance for this equipment requires preparation and planning followed by use of logistical equipment that sees operators devote at least 4 hours to checking all sensitive recloser components. This includes verifying automation and signal quality for SCADA, monitoring batteries as well as cleaning and lubricating all connections. Finally, earth resistance is verified.

CLICK TO ENLARGE

EDPD’s HV/MV Network Maintenance Manager adds that effective maintenance requires more than simply replacing items such as insulators, arresters or other line components when they fail. He says it is also necessary to determine the root cause of any problem and understand the various degradation processes at work.

To help engineers identify the cause of every incident leading to a line or cable outage, failed components are analyzed by ad hoc teams comprised of specialists in maintenance and that particular equipment’s technology. Another goal is to assess residual performance. In this regard, EDPD has mandated its internal laboratory, Labelec, to carry out tests on most failures. Based on findings, specific preventive and corrective measures are identified and then implemented on a case-by-case basis. For example, apart from studying the cause of recent arrester failures and predicting residual lifetime of punctured porcelain, Labelec also tests a range of high voltage equipment and accessories. One example is a fractured 225 kV silicone rubber insulator investigated to determine the specific failure mechanism involved.

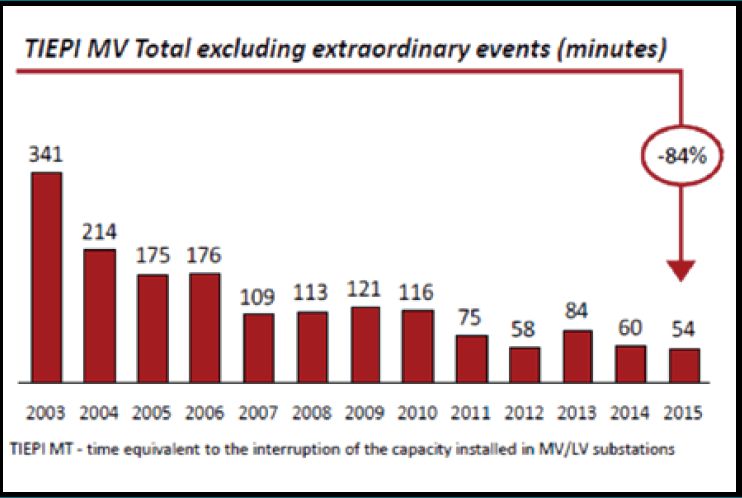

Implementation of the Operation Plan & Procedures for Crisis Situations as well as application of technologies such as distribution automation, fault passage indicators (dedicated to rapid location of short circuit and earth faults on MV systems), overhead line auto-reclosers (OCR) and underground grid automation units (URR) have had impressive results. In 2015, EDPD scored a TIE of less than 54 minutes, which marked the lowest equivalent interruption time of its installed capacity since 2011. Additional key performance indicators such as System Average Interruption Frequency Index (SAIFI)) and System Average Interruption Duration Index (SAIDI) also showed substantial improvement