Pollution Performance of Composite Hollow Core Insulators with HTV LSR Housings by Eric Moal

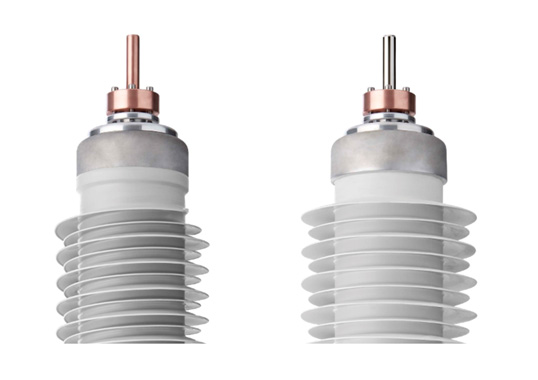

Silicone rubber materials exhibit distinct properties that are advantageous for application in HV outdoor insulation. These include stability against UV and ozone, good dielectric properties, resistance against high temperatures, excellent hydrophobic properties as well as resistance to arcing and tracking. High temperature vulcanizing and liquid silicone rubbers have been successfully applied for over 30 years as elastomeric housings for composite insulators. Moreover, process technology and formulations have been developed to meet the high quality requirements needed for HV outdoor applications. HTV rubbers are typically applied in housings of large composite hollow insulators, usually manufactured with extrusion technology, and also for hollow and solid core insulators made by injection moulding. LSR rubbers, by contrast, are typically applied in housings of large composite hollow insulators manufactured using injection moulding technology. This presentation reviews the long-term performance of grades of HTV and LSR rubber materials that have been specially adapted for HV outdoor applications. Evaluation of relative performance is based on long-term service experience in the field, which is then compared to results obtained from material tests in the laboratory.