Performance of RTV-Coated Toughened Glass Insulators in Zones of High Contamination by Samuel Arturo Asto Soto.

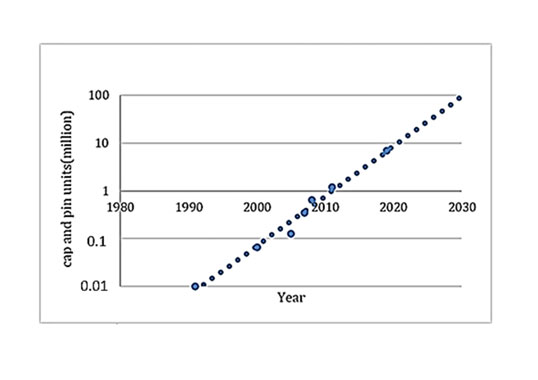

To reduce maintenance costs from frequent washing of insulators on transmission lines in coastal areas with heavy salt pollution, high humidity and scarce rainfall, glass and porcelain insulators were replaced by 12,000 polymeric units between 1996 and 2004. However, after only a few years, 17 failures occurred due to breakage of the core of insulators installed in extreme contamination areas. After investigation, it was decided to replace polymeric insulators installed on coastal transmission lines by RTV silicone coated glass insulators. The coating would allow maintaining reliability of the line, eliminate failures due to core fracture and result in savings by significantly reducing fines as well as need for frequent cleaning. Regarding frequency of replacement or change of coated insulators, this was initially set at 10 years based on manufacturer recommendation and experience elsewhere. However, since 2015, there were cases of failure of the coated insulation, causing disconnection of the lines. This resulted in revision of the strategy and start of a program of cleaning such insulators in areas of extreme pollution once every 4 years and once every 6 years in areas of high pollution. Subsequent experience showed that, in areas of extra high pollution, coated glass insulators did not recover their hydrophobic properties after cleaning, leading to the need for cleaning in a shorter time frame than before. This presentation reviews experience with regard to application of RTV coated glass insulators on transmission lines along the coastline of Peru. It discusses performance and outlines decisions in regard to the best replacement strategy as well as proper maintenance needs.