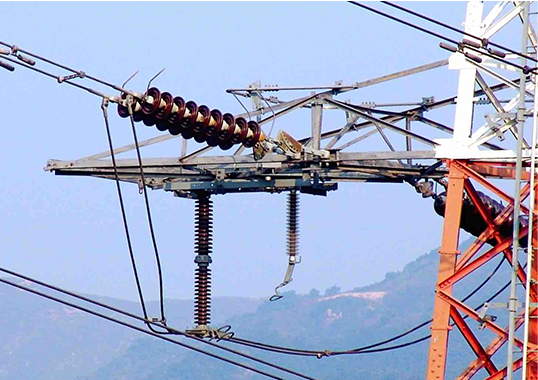

It is not unusual for utility engineers today to manage ‘fleets’ of overhead lines, some installed in the 1960s and 70s and now over 50 or even 60 years old. This time span is the center of the age range where overhead groundwires (OHGW) begin to fail but well before other components such as ceramic insulators and towers normally deteriorate.

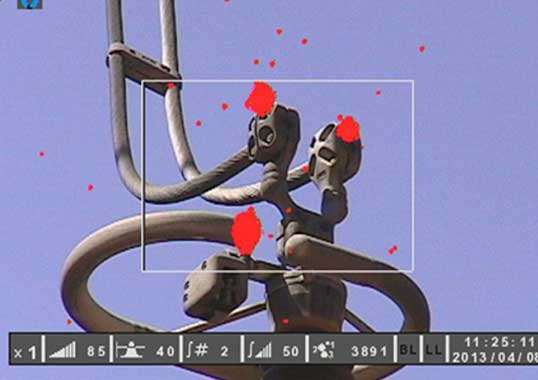

Establishing end-of-life criteria for OHGW involves inspection of visual appearance and extent of corrosion. Concerns about the metallurgical condition of the steel wires are addressed with tests such as torsional ductility, which measures number of twists before wire samples break, as well as by measuring changes in tensile strength versus original ratings.

This edited past contribution to INMR by T&D expert, Dr. William Chisholm, reviewed the benefits and drawbacks of the various options should replacement be needed.

After receiving a report that an OHGW has reached its end-of-life, the utility engineer is confronted with decisions and also multiple possible solutions, that include:

• Direct OHGW replacement with the same material and size of wire. This option may be easy to specify but calls for more difficult decisions when it comes to either scheduling an outage for an extended period or employing specialized crews for carrying out the replacement with live line methods. Whatever the choice, it is certain that such a replacement project will cost many times more than the original investment.

• A second option with high functionality could see substitution by an optical fiber groundwire (OPGW) system. With its multiple fibers wrapped around the central core, wire sizes and materials can be selected to best protect against charge ablation damage and moisture ingress over the long-term. By way of compensation for their higher cost, OPGWs offer utilities massive and highly marketable increases in point-to-point communications capabilities. The integration of utility optical fiber networks with local wireless, low-power-consumption networks could even become an incentive to live within view of a power line.

• Another option offering improved service performance would be to specify transmission line surge arresters at the same time that the OHGW is being replaced. Line surge arresters can be used to convert bottom phases temporarily to ‘under-built groundwires’ (or UBGWs) that reduce voltage stress under lightning conditions. Unlike copper grounding systems at the tower base, such UBGWs are always secure against theft and corrosion.

• Yet another solution could be termed the ‘leave it empty’ option. This would see the OHGW removed but not replaced. The same lightning protection could then be achieved by fitting line surge arresters of sufficient energy rating. Any lightning ablation damage normally occurring on the OHGW would then transfer to the aluminum phase conductors, perhaps shortening their residual service life or requiring more frequent inspections. While the role of the OHGW in managing fault current on power systems is important, this function can equally well be provided with adequate grounding at each tower and with reduced fault duration through improved relays and switchgear. Balanced against these drawbacks are benefits such as reduction in flashovers from excess sag or relative conductor motion under icing conditions. There is also a reduction in induced current losses meaning greater energy efficiency.

• The ‘replace with something smaller’ option could put a replacement OHGW or OPGW below rather than above the phase conductors. Primary lightning protection is then transferred to line surge arresters installed on all upper phases. Permanent UBGWs are easier to install below the phases. Also, in this position they continue to provide low, multiple-grounded impedance to ground for managing fault currents. Greater overturning forces associated with reduced UBGW height as well as ease of access to any optical fibers are the additional benefits with this option.

Utility engineers should recognize that when OHGWs fail, the situation also offers valuable resource options to consider when making the best decision on how to handle the need for replacement.