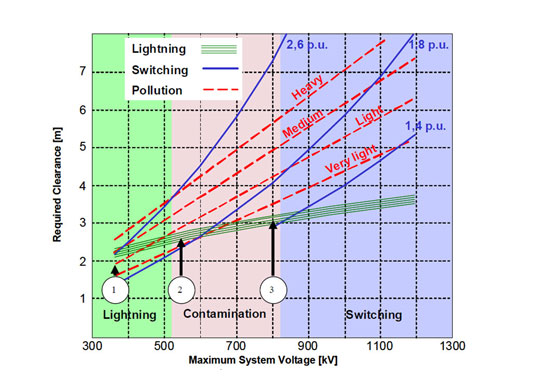

Metal oxide surge arresters have high reliability and will function as intended almost indefinitely, assuming that they have been well designed, properly manufactured and operated within their specified range of applied voltage, temporary overvoltage, surge magnitude and surge energy. Nonetheless, arresters do occasionally fail in service. This implies that one or more of these variables has been violated or that the arrester may have been damaged during handling or installation. Failure in such cases usually means that the arrester has suffered an internal short circuit, placing a fault, e.g. line-to-ground fault, on the system. Almost invariably, this will result in operation of a circuit-interrupting device such as a breaker, recloser, fuse, etc., thereby causing a disruption in service. If the arrester is equipped with a disconnector, the disconnector should operate when fault current flows following arrester short circuit. This will isolate the arrester either from the ground or from the line, depending on where the disconnector is installed. Then, upon re-energization, the failed arrester is no longer in the circuit electrically and service can be con-tinued albeit with a reduced level of surge protection. Station arrester failure will typically cause a system lockout until either that portion of the substation can be by-passed or until the arrester is physically removed from service. While it is desirable to avoid arrester failure at all times, the consequences of sta-tion arrester failure are typically far more severe than is the case for distribution arresters. Typically, there will be considerably greater disruption in service and the cost of replacing a station arrester is orders of magnitude higher.

In this edited past contribution to INMR, experts at Hubbell Power Systems in the United States outlined methods to monitor condition of arresters installed in a power system. He also presented the basis behind each as well as comparative advantages and drawbacks.

Goals of Field Testing

A program of field testing arresters is undertaken by users with the goals of determining if an arrester is nearing end of life, predicting when end of life will occur and evaluating if the arrester is still providing protection to the insulation. The first two of these objectives can be reasonably achieved but the third is not yet practical in a field environment. Fortunately, with today’s MOV arresters and all the design tests that must be passed, there is virtually no duty that can impact an arrester’s ability to protect.

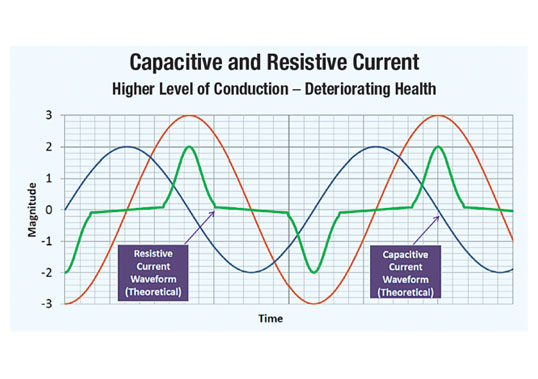

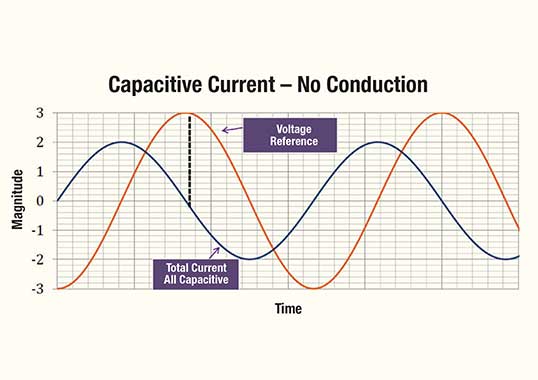

To better understand end of life testing, it is necessary to know how a surge arrester behaves under power frequency conditions – not only when the arrester has aged but also when it is tested in the factory prior to being shipped. Under normal line-to-ground power frequency voltages, surge arrester current is nearly all capacitive. Fig. 1 shows the relationship between voltage and current on a new surge arrester.

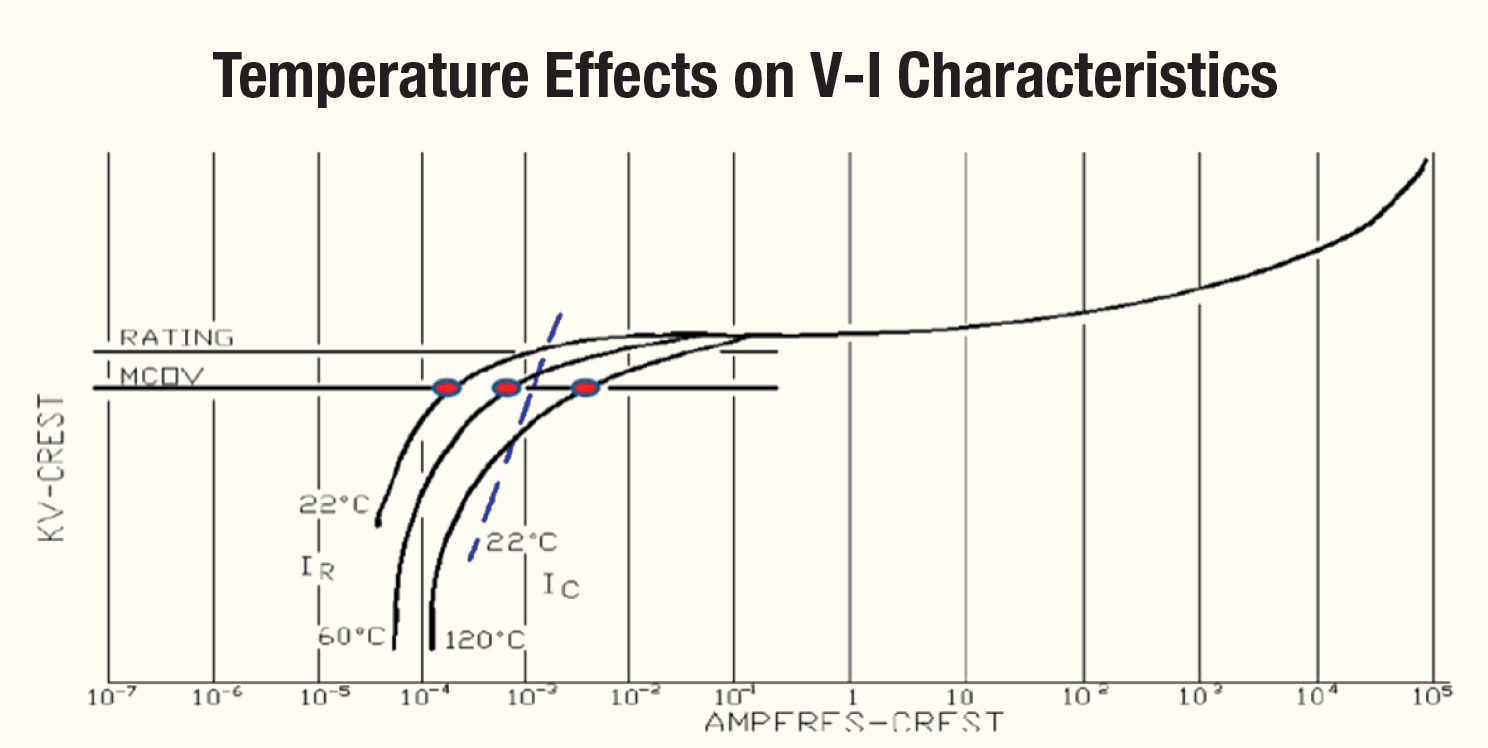

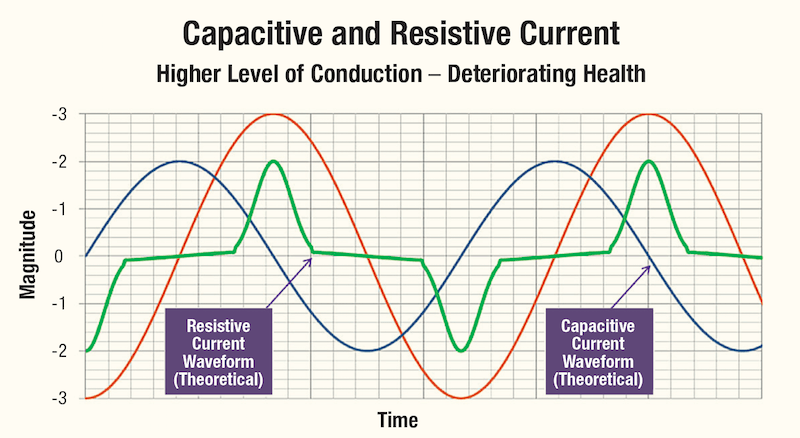

As voltage on the arrester increases, current waveform becomes much more resistive in nature. This characteristic is also true if voltage remains constant but internal temperature of the arrester increases for some reason. Given this, monitoring the resistive component of current over time is key in efforts to evaluate the internal state of an arrester and to predict its ultimate demise. MOV blocks exhibit a negative temperature coefficient and, as such, the resistive component of current increases as block temperature rises. Figs. 2 and 3 demonstrate these characteristics.

Failure Modes

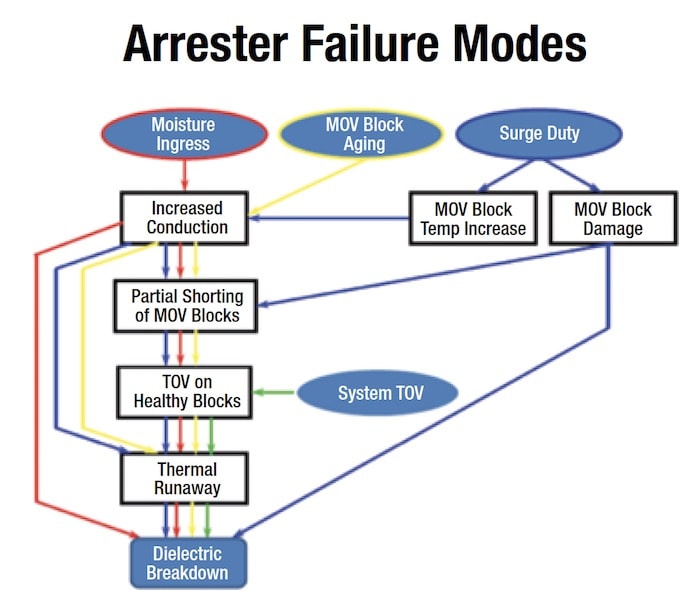

Almost without exception, arrester failure results in a complete short-circuiting of the unit inside its external housing. While an arrester could flashover externally without its external air gap being compromised (e.g. by contact with wildlife or vegetation), the MOV blocks inside typically prevent terminal-to-terminal voltage reaching a point where external flashover will occur. In all scenarios, failure is ultimately the result of dielectric breakdown whereby the internal structure of the arrester has deteriorated to the point where it is unable to withstand the voltage applied to its terminal – whether this be normal system voltage, temporary power frequency overvoltage, e.g. following external line faults or switching, or lightning or switching surge overvoltages. There are a variety of ways an arrester could reach such a state, although their rate of occurrence is rare.

Moisture Ingress

Probably the most common root cause of arrester failure is moisture ingress to the interior. This suggests that it was not well designed or not properly manufactured or that it may have been physically damaged by external force that compromised its sealing system.

Temporary Overvoltage (TOV)

Under normal operating conditions where an arrester is energized at its maximum continuous operating voltage (MCOV), temperature of the MOV blocks rises to just slightly above ambient. A point is soon reached where the heat being generated by the blocks is perfectly matched by the heat the arrester dissipates into surrounding air. If the power frequency voltage across the arrester increases, e.g. as a result of a sys¬tem disturbance, fault or switching operation, the MOV blocks conduct more current and begin to rise in temperature. If the overvoltage is of sufficient magnitude, the heat generated by the MOV blocks will always be greater than what can be dissipated and there is potential thermal runaway.

Ageing of MOV Blocks

In the early days of MOV arrester technology, blocks supplied by manufacturers exhibited characteristic ageing whereby their power dissipation at a given voltage slowly, but contin¬uously, increased over time. The effect of such behavior on arrester performance would be similar to that for TOV, namely that after some time in service, the power (heat) generated by the blocks would be similar to that resulting from a TOV when the blocks were new. At some later time, the heat generated would be equivalent to that generated by a higher TOV than when the blocks were new. Ultimately, the heat being generated could reach a point where stable operation could no longer be maintained. These days, after three decades of significant improvement in processing technology, MOV blocks produced by major manufacturers exhibit a characteristic whereby the power dissipation actually decreases with time at a given voltage. The implication is that they become more rather than less thermally stable over time, and therefore arrester failure as a result of block ageing is unlikely.

Thermal Runaway Resulting from Surge Duty

Surge duty referred to here is that resulting from relatively high current surges due to lightning or switching of long lines or capacitor banks. Some of these surges may have very high amplitudes but relatively short duration, e.g. lightning surges, while others may have much longer duration but with significantly lower amplitude, e.g. switching surges. All have a certain charge content that, when passed through an arrester’s MOV blocks, result in a certain amount of energy absorbed by the blocks. This absorbed energy results in an almost immediate, i.e. adiabatic, heating of the blocks. If the input of energy is too high, temperature rise of the MOV blocks may be such that the arrester is pushed into a thermal runaway condition.

Damage to MOV Blocks From Surge Duty

As discussed, one manifestation of energy absorbed by MOV blocks is rise in their temperature. However, if the energy is of sufficiently high magnitude and deposited into the blocks in a sufficiently short time, the blocks may be irreversibly damaged. For example, the thermo-mechanical shock imparted to the blocks may cause them to crack into pieces. In other cases, a block may be punctured in a localized area, either partially or completely through its body. In yet other cases, pinhole type failure can occur at the edge of the block causing material to be removed from the outside peripheral surface. Typically, each such type of physical damage is accompanied by degradation of the blocks’ electrical integrity. This degradation will be either in inability to sustain another energy event without complete electrical breakdown or reduction in ability to support normal operating voltage. Both will sooner or later result in complete arrester failure.

Fig. 4 outlines typical failure modes of MOV surge arresters in a flow charge format. In all cases, final mode of failure will be increased conduction, ultimately leading to complete dielectric breakdown. Therefore, measuring temperature and/or resistive component of current is key to monitoring the internal condition of a surge arrester.

Methods of On-Line Monitoring

Utilities invariably prefer an on-line measurement method since this does not require a substation to be taken out of service in order to perform an evaluation. For all methods discussed below, it is important that a baseline measurement be established and that data be taken over time to look for trends that indicate increasing resistive current. As far as what measurements are acceptable, this value will vary between manufacturers. As such, the supplier of the specific arrester being evaluated should be contacted for input on appropriate limits.

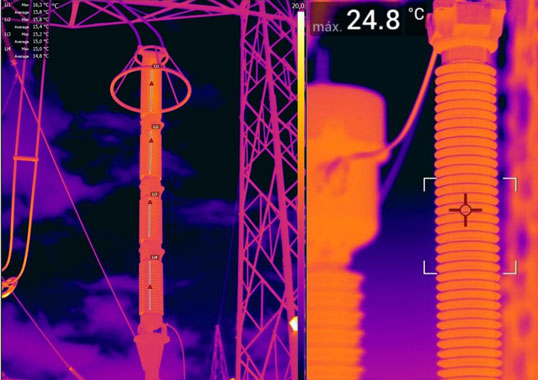

Infrared Imaging

Increases in power losses that occur in case of a degrading arrester will result in increased temperature of the MOV blocks, at least along some portion of the arrester. Unfortunately, MOV block temperature is not a characteristic that can be directly measured in a conventional arrester. Most utilities therefore use indirect means such as infrared thermography.

The heat generated by the MOV blocks inside an arrester is dissipated to the outside by conduction, radiation or convection. For sufficiently high heat generation, the outside surface of the housing can become elevated above ambient temperature. The heated surface then emits radiation that can be detected by an infrared sensor, thereby allowing an estimate of surface temperature. The device used could be an infrared thermometer that merely registers temperature of the spot or of the small area on which the device is focused. Or it can be an infrared camera that captures a thermal image over a wider area, providing a temperature profile over the arrester’s entire length or of a major portion. This non-contact method of measurement clearly has advantages since it can be conducted from a safe distance, quickly and at practically any time. The technique is not, however, without potential errors and always needs careful interpretation. The amount of radiation emitted from a heated surface depends on its emissivity. A shiny surface with low emissivity will emit less radiation at a given temperature than a dull surface with high emissivity at that same temperature. The ‘apparent’ temperature registered by the infrared device could therefore be different although the actual temperature is the same in both cases. Other problems can occur with reflected radiation from nearby sources or from the sun. Such problems are not insurmountable but need to be taken into account. It is advisable that individuals taking the measurements have received proper training in taking and interpreting infrared thermographic measurements temperature, it is not always easy to determine their significance. As for off-line techniques, there is no single ‘hard-and-fast’ threshold delineating a healthy arrester from a degraded arrester. Again, judgment needs to be employed. Without knowing details about the thermal properties of the arrester ‘package’, it is not straightforward to translate temperature measured on the outside of the housing to temperature of the MOV blocks inside. Different types of arrester design and construction will differ in this regard. Simply because an arrester has some region that appears hotter than others is not necessarily an indication that a problem exists or is emerging. Particularly on high-voltage, multi-unit arresters, it is likely that temperature near the top will be higher than at lower points. This is because there is inevitably some degree of non-linearity of voltage distribution along the MOV block column – even with grading rings employed. Blocks near the top of the arrester are typically stressed above the average for the entire arrester. Consequently, they will likely be running somewhat hotter than the average for the entire arrester.

Arrester manufacturers typically advise customers to take thermal profiles of arresters on all three phases at a particular location over a short timespan to avoid issues with changing ambient conditions and to look for differences between these profiles. It is unlikely that a problem of degradation exists in all three arresters and of even lower probability that degradation is progressing at exactly the same rate in all of them. If there exist relatively modest variations in temperature along an arrester, e.g. less than 5-10°C, yet this is the same for all three arresters, there is probably no reason to be concerned. The key is examining for a significant difference, i.e. one that has a distinctly different temperature profile to the others. Even then, it does not necessarily mean that the arrester in question is ‘bad’ but rather might suggest that it be monitored more regularly to determine if the difference increases.

Resistive Component of Current

It is impractical to monitor arrester power losses in the field and MOV block temperature cannot be directly measured. But one quantity that can be monitored directly and continuously is arrester current. Such measurement requires that the arrester be isolated from ground by placing it on an insulating sub-base, then connecting the isolated base to ground via a conductive path that bridges the sub-base. A device connected in this conductive path can be used to obtain a signal that is proportional to arrester current. This device could be a resistive shunt of several hundred to a few thousand ohms, e.g. a 1 kΩ shunt would provide a 2 volt signal for an arrester current of 2 mA. Alternatively, an appropriately sized current transformer could be placed around the conductor, e.g. a current transformer with 1:100 turns ratio and 10 kΩ burden would provide a 200 mV signal for an arrester current of 2 mA. In either case, protection needs to be provided. A small MOV across the terminals of the measuring device will limit output voltages should the arrester be called upon to limit surge overvoltages. This could result in short duration impulse currents of many kA. Most arrester manufacturers offer devices to measure arrester current. These relatively simple devices provide a measurement of the total current flowing through the arrester, typically in terms of peak magnitude or peak/√2 to provide a quasi-rms value.

The above would suggest that monitoring the resistive component of current would provide a better indication of arrester health than monitoring total current. This is true but unfortunately while total current can be directly and easily measured on in-service arresters, it is difficult to extract the resistive component. As indicated, the peak of the resistive component occurs at the instant of the peak of the voltage across the arrester. If accurate information regarding the voltage waveform were available, it would be possible to determine the value of the total current at the instant of voltage peak, thereby yielding the peak value of the resistive component. This is possible in a controlled laboratory setting but virtually impossible to do in the field. Obtaining an accurate measure of the waveform of the voltage applied to the arrester being monitored would require an expensive and extremely accurate voltage divider with zero phase-angle error.

3rd Harmonic Measurement

If an arrester at normal operating voltage conducts increasing amounts of current because of degradation of its volt-amp characteristic, the resistive component of arrester current is a far more sensitive measure of degradation than is total current. This is because total current is dominated by the significant capacitive component until the arrester has de¬graded substantially. However, the resistive component is not readily extractable from total current, especially in the case of in-service field measurements. Simulation and experimental data demonstrate that the 3rd harmonic component of arrester current provides a reasonable and indirect means of estimating the resistive component. Therefore, it can serve as a means to monitor degree of degradation of the arrester’s conducting properties. In the field, measurement of the 3rd harmonic component of current can be easily undertaken on energized arresters and commercially available instruments are available for this purpose. In considering any 3rd harmonic monitoring system, an important factor to take into account is system frequency. A device designed for a 60 Hz system will not function correctly on a 50 Hz system.

Absolute Temperature

The ideal monitoring method would appear to be direct measurement of internal block temperature since this would be the best reflection of change in resistive component of current. Surge arresters with built in thermal monitoring devices do not require use of insulating sub-bases and are not as susceptible to impact of external leakage currents. However, the present state of arrester technology places this monitoring method still out of reach.

Power Loss at MCOV

For almost all underlying causes of degradation of an arrest¬er’s performance, the resistive component of current increas¬es over time. With steady applied voltage to the arrester, this results in an increase in power losses. However, measuring power loss of an arrester in service is not easy. It requires sep¬arate measurements of voltage applied to the arrester and of arrester current, these quantities then being multiplied and integrated over time. To accurately determine power loss, there must be no phase shift errors in the voltage and current measurements. In other words, the signal that represents applied voltage must be exactly 90 degrees out-of-phase with the capacitive component of the signal that represents current. Even small phase errors can result in large errors in power loss measurement. Moreover, measurement of voltage requires expensive equipment such as a high voltage divider or potential transformer. For these reasons measurement of power losses on assembled arresters at normal operating voltage is something only done in a high voltage laboratory or in a manufacturer’s factory.

Conclusions

Since the rate of deterioration of surge arresters can vary greatly, it is recommended that testing be performed as often as reasonably possible, given users budgets or other constraints. It is also important to maintain records over time and compare the latest information with baseline data. It is possible to damage an MOV arrester from overvoltage and this can even happen accidentally during the course of field-testing. For example, high potential testing is not recommended for MOV surge arresters due to risk of damage. Finally, to ensure that only internal arrester currents are being measured, it is important to ensure the arrester surface is clean and dry.