Mechanical Testing of Connection Leads for Transmission Line Arresters by Martin Hughes

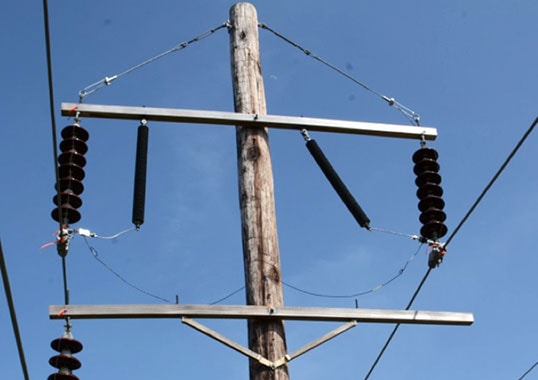

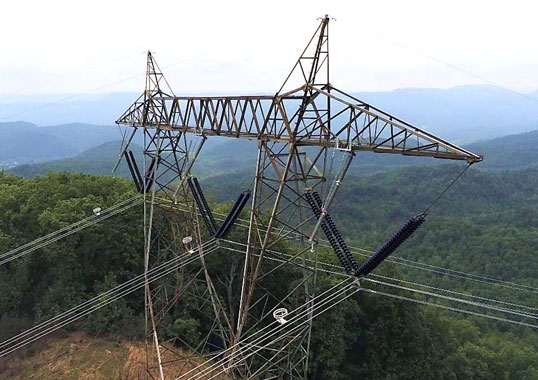

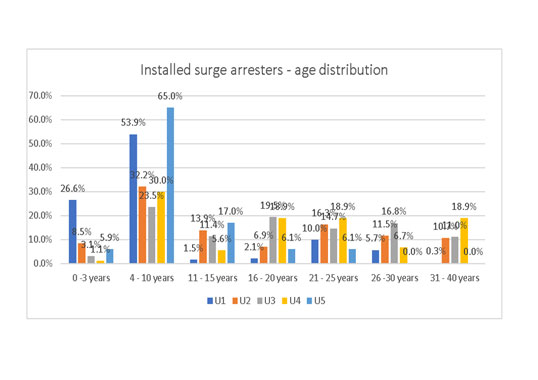

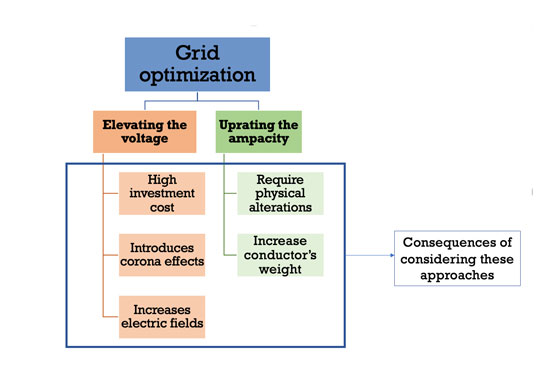

Transmission line surge arresters are applied on overhead lines to improve outage performance and, particularly in cases of some EHV lines, to limit magnitude of switching overvoltages. There are basically two types: Externally gapped line arresters (EGLAs) and non-gapped line arresters (NGLAs). In places such as the United States, most are NGLA type, comprised of a column of metal oxide varistors packaged in a polymeric housing reinforced with fiberglass. The arrester is installed between phase conductor and tower with connection leads. One end is typically fitted with a disconnector to break the electrical connection in the event of arrester failure. Previous EPRI reports have described the various possible NGLA installation configurations as well as associated problems found during line inspections. While service experience shows that application of NGLAs often improves line performance with relatively few failures, many utilities have reported that installations are often compromised by mechanical issues such as connection lead or disconnector failures. Current arrester standards do not include mechanical tests or requirements for arrester connections, however, IEC 60099-5 suggests an arrester life expectancy of at least 25 years. This presentation summarizes results of a multi-year EPRI research project to identify and understand causes of lead breakages with a view to formulating functional requirements that could eventually be included in user technical specifications.