Energias de Portugal-Distribuição, the main Portuguese DSO, has worked on best practice to restore power in emergency situations and to minimize duration of resulting outages. Various solutions were identified to reduce outage time, which were then incorporated into EDP’s Operation Plan and Procedures for Crisis Situations. This edited past contribution to INMR by EDP’s Vitor Miguel Ribeiro and Tomas Andresen Abreu discussed criteria behind efforts to mitigate consequences of failures on the MV network and presented a customized solution for emergency as well as routine maintenance

The emergency broken concrete pole solution was developed to quickly replace damaged poles and allow provisional repair of concrete poles that break at 2/3 of their height above ground. EDP criteria for an acceptable solution in these situations included the need to be flexible, easy to store and capable of being assembled without heavy machinery. It also had to allow for manual transport or using a small pick-up to the assembly site. Finally, the kit had to accommodate a range of different conductor cross-sections up to 160 mm2 while conforming as well to the national standard, EN 50341. The Broken Concrete Pole Kit was the solution that met all these requirements.

The modular structure suits different pole dimensions while enabling extension from point of breakage by 1 m when the pole breaks near the upper end. It can be used with conductors up to 160 mm2 and supports a global 1000 daN horizontal force and 1100 daN vertical load. Installation of the kit is demonstrated in Fig. 2.

TThe emergency pole kit is stored on shelves and there is a single box for each containing all accessories needed to assemble on the pole. EDP Distribuição has already placed such kits in strategic locations across Portugal, ready for use in case of emergency. The solution is intended to be ready for installation in short time, thereby reducing any extended outage as well as the considerable cost of generators.

Pole-Top Emergency Kit

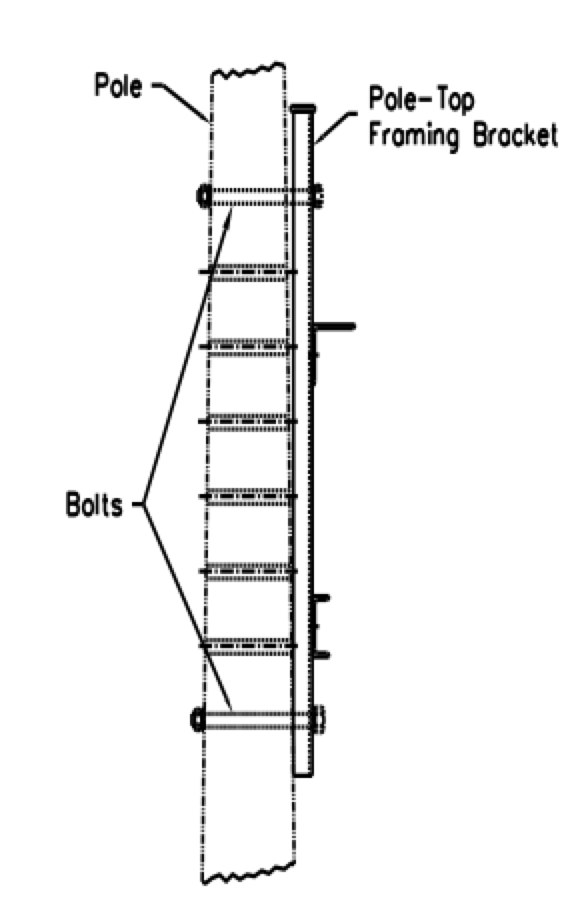

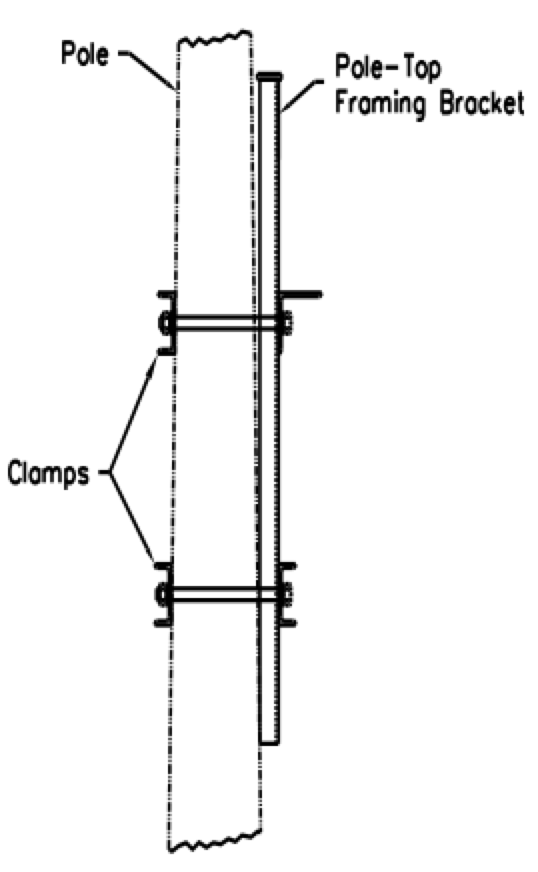

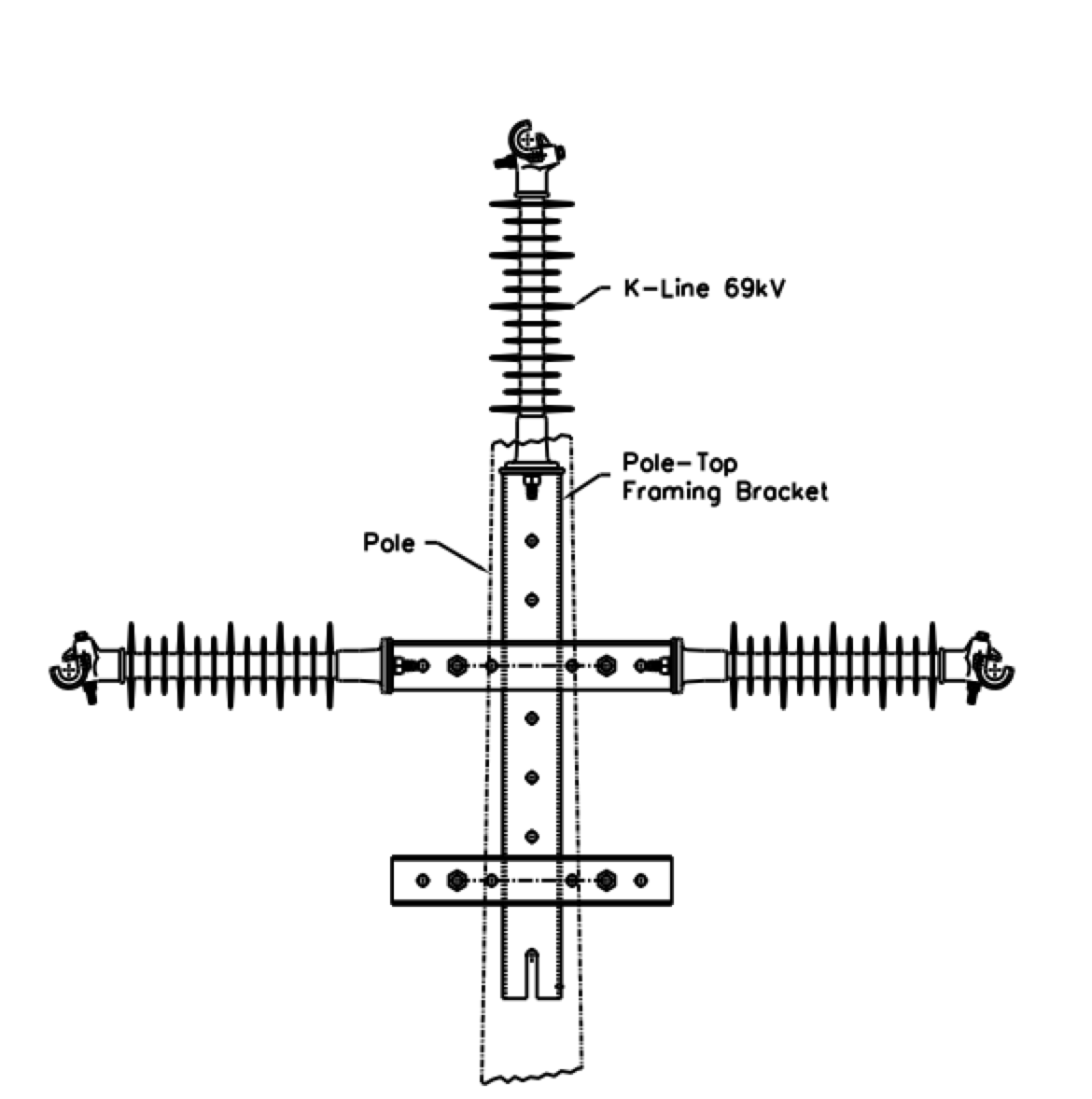

The Pole-Top Emergency Kit was developed by K-Line Insulators (KLI), in cooperation with EDP-Distribuição, for quick restoration of power line structures damaged by storms. This customized kit was designed to support three phases on line post insulators for tangent and small line angle structures but is also suitable for direct mounting on the structure, utilizing through bolts or by clamping around the structure (see Figs. 3 and 4). Such choice of mounting options makes the kit, with its minimal number of components, not only versatile but also easy and quick to install.

The kit was intended mainly for temporary repair of a pole top mechanical failure but can remain in service for longer periods of time if necessary. To maintain a relatively light pole-top framing bracket, standard structural steel shapes were used in the design. By keeping the bracket low weight, only light duty machinery would be needed and this would ensure easy access to the majority of sites where pole failures might occur.

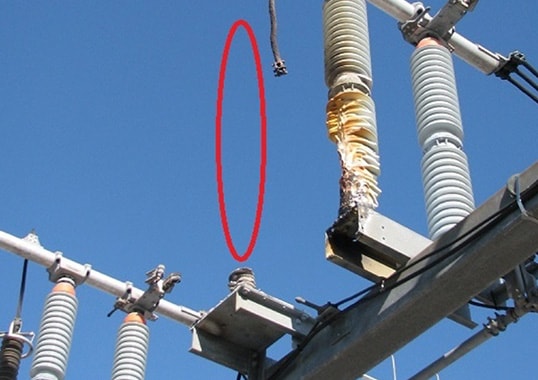

The center member of the bracket is a C-channel strong enough for transverse and longitudinal loads and also adaptable for mounting on flat or round surfaces. The horizontal member for the two outer phases is an angle iron able to support vertical and longitudinal loads. The bracket is hot-dipped galvanized for corrosion resistance. KLI’s 69 kV line post insulators were used to provide the same conductor separation as in the original framing and to extend the center phase above the damaged structure due to loss of the pole-top section (see Fig. 5).

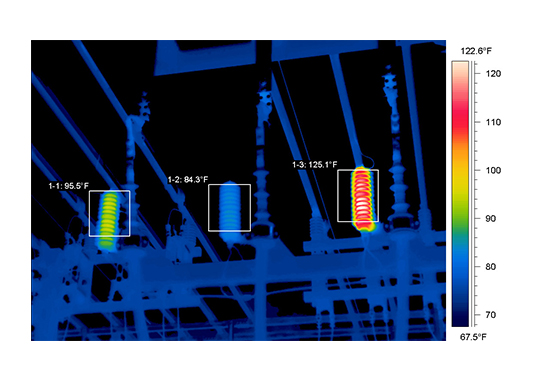

The 69 kV silicone line post offers a high insulation level that adds to performance of the line. On a 33 kV line, for example, this insulator provides a unified specified creepage distance (USCD) of 72.7 mm/kV – well above that needed for even heavy site pollution severity, defined by IEC as 53.7 mm/kV. Wet flashover voltage of the insulator is 190 kV – high in comparison to the 19 kV phase-to-ground operating voltage and representing a safety factor of 10. The insulator creepage distance along with high wet flashover voltage help prevent flashovers and reduce leakage current that can result from heavy contamination under wet conditions. Insulation impulse strength is increased to 360 kV based on the insulators alone, thereby minimizing flashovers due to lightning surges.

The mechanical strength of the pole-top bracket and line post insulators was designed to have the equivalent loading capability. Design specifications call for a maximum ultimate vertical and transverse load of the bracket and line post insulator of 11 kN. Maximum design loads are thus 50% of the ultimate loads. The line post insulators have an integral clamp that accommodates a wide range of conductors and all parts are captive. The clamp is safe, quick and easy to work with – designed to be operable with either live-line sticks or rubber gloves.

Training Sessions

Training sessions were developed to familiarize EDP-Distribuição teams as well as external service providers with proper methods for installing the assembly kits. The main advantages identified by teams using these kits included:

• Light weight;

• Ease of assembly and installation;

• Mounting kit time of only about 30 to 35 minutes.

During extreme storm conditions, a break of the concrete pole normally occurs at the top, as in Fig. 6.

Figs. 7 to 10 illustrate kit installation sequence by a line crew.

Summary

The pole-top emergency kit was designed for quick restoration of a mechanically failed pole top. The kit is light and easy to install and its design exceeds all EDP Distribuição electrical and mechanical requirements while its insulators permit safe subsequent operation using live line work techniques. All technical solutions that can minimize outage time of a MV network in crisis situations, such as heavy storms, are of extreme importance. As a result, EDP Distribuição devoted much effort supporting development of this broken concrete pole extension.

Whenever pole top mechanical failure situations occur, this equipment will help teams in the field conduct quick repair and minimize customer outage time. It should also be noted that design tests, field tests and actual application of these solutions to real emergency situations all proved successful. This experience demonstrates that power utilities and their key supply partners can work together to generate new solutions to real operating problems.