It has long been known that corona can lead to insulation failure. However not all aspects of the problem are fully understood and are still being researched, including magnitude and duration of corona to initiate degradation, best detection methods and development of suitable tests to predict performance in its presence.

When it comes to composite insulators, corona activity can originate from hardware, voids within the material or from interfacial defects. Most of the light produced by such corona has a wavelength shorter than 400 nm and therefore falls in the UV range. By contrast, most solar radiation is in the 400-700 nm visible range – the shorter wavelengths filtered by the earth’s ozone layer. In fact, some peaks in the UV region of the corona spectrum match or exceed those in the solar spectrum. Polymeric materials are more susceptible to degradation from UV produced by corona than from solar radiation, particularly if the corona takes place close to the material. Corona ruptures stable oxygen molecules (O2) to create radicals that combine with the molecules to form ozone (O3). The ozone then attacks double and triple bond sites in elastomeric materials such as silicone rubber or EPDM. The result is cracking. Even tiny amounts of ozone in the ppm range are sufficient to initiate cracks, however the time required for this depends on material formulation.

When it comes to composite insulators, corona activity can originate from hardware, voids within the material or from interfacial defects. Most of the light produced by such corona has a wavelength shorter than 400 nm and therefore falls in the UV range. By contrast, most solar radiation is in the 400-700 nm visible range – the shorter wavelengths filtered by the earth’s ozone layer. In fact, some peaks in the UV region of the corona spectrum match or exceed those in the solar spectrum. Polymeric materials are more susceptible to degradation from UV produced by corona than from solar radiation, particularly if the corona takes place close to the material. Corona ruptures stable oxygen molecules (O2) to create radicals that combine with the molecules to form ozone (O3). The ozone then attacks double and triple bond sites in elastomeric materials such as silicone rubber or EPDM. The result is cracking. Even tiny amounts of ozone in the ppm range are sufficient to initiate cracks, however the time required for this depends on material formulation.

Although most modern elastomers are stabilized against this threat, some eventually succumb to ozone attack should its concentration become sufficiently high. Corona also produces oxalic and nitric acids in the presence of surface moisture from humidity, dew or fog. Depending on pH, this can also locally degrade polymers. Corona can even ‘drill’ holes in a material, suggesting that degradation is not solely due to chemical attack by ozone. In fact, researchers have calculated the temperature at the tip of the discharge and shown it to be high enough to cause ‘evaporation’ of even inorganic materials. There is also suggestion of mechanical attack, like sandblasting, due to the impact of repeated discharges on a material. It is indeed rare in power engineering that any one physical phenomenon can trigger so many possible modes of degradation.

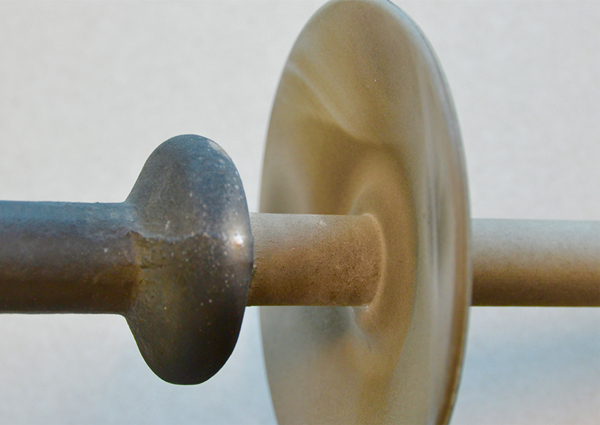

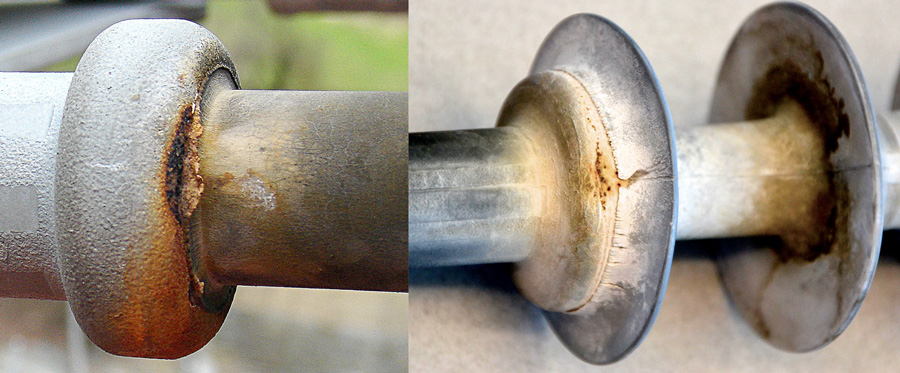

To illustrate the potential impact of corona, past research involved ground-based inspection of composite insulators on 115 kV, 230 kV and 500 kV lines in the U.S. southwest using a corona camera and binoculars. Several 230 kV towers were equipped with composite insulators with and without corona rings on adjacent phases. The 115 kV insulators did not have corona rings whereas the 500 kV insulators had rings on the line as well as on the ground end hardware. Given the dry conditions of the service territory, the utility operating these lines had decided not to replace the 230 kV insulators not equipped with corona rings. This allowed comparative study of the effects of corona on composite insulators since all other factors were the same (i.e. same design, material, manufacturing details, location and system voltage). The corona observed on these insulators, many of which had been in service for over 25 years, was sporadic and originated from hardware.

The 230 kV insulators being evaluated comprised three generations of composite insulator technology. Some were removed for further examination and it was found that the shed closest to the line end without a corona ring exhibited minor to serious changes in the form of hardening, cracking and discoloration. It was clear that these insulators were approaching their end of useful life and indeed would have probably already failed in locations having more precipitation.

By contrast, none of the insulators equipped with corona rings showed such degradation. This demonstrated forcefully that when it comes to composite insulators, design and need for a corona ring depend not only on voltage level but also service environment. For example, in the case of insulators in environments with heavy contamination, high altitude or frequent wetting, it is prudent to have a line end corona ring even at lower transmission voltages.

[inline_ad_block]