[inline_ad_block]

Development of latest generation compact UV cameras has been a positive development for utilities, allowing for more practical routine inspection of lines and equipment. For example, it has not always been possible to say anything definitive about the condition of an insulator, especially composite types, based solely on visual inspection. This past INMR article, contributed by Professor Ravi Gorur, summarized research aimed at providing a means to assess the severity of corona observed on an insulator. Different insulator designs using silicone rubber and EPDM housings were examined and correlation of the visual images of corona with discharge magnitude was established. This information proved useful in identifying discharge patterns that pose threats to the integrity of an insulator.

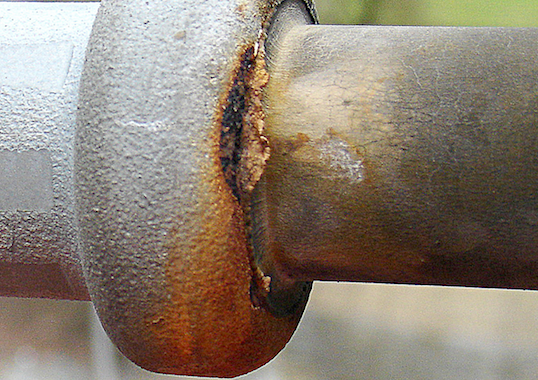

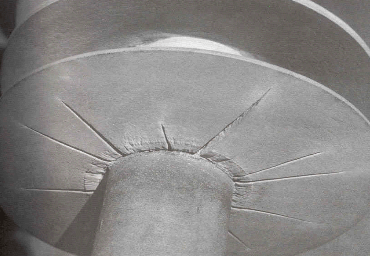

Corona discharges can be a significant threat to the integrity of composite insulators due to their organic housing materials. Moreover, for transmission class insulators (69 kV and above), corona can be problem not only in contaminated conditions but also in clean environments. This is important since the majority of composite insulator applications are installed in relatively clean or only lightly contaminated areas. On such insulators, localized corona can be present for an extended time due to inadequate hardware design, damaged hardware or deficient interfaces due to improper design or manufacturing. In most transmission networks it is difficult to avoid corona, especially under wet and contaminated conditions. Hence, knowledge of corona discharge magnitude and damage threshold of the housing material becomes essential. Fig. 1 shows damage caused by corona on a composite insualtor in service and it is clear that the insulator is at an advanced stage of degradation. Since any cracks in the housing can expose the fiberglass core to moisture, an exposed rod can fail by tracking, erosion or brittle fracture leading to premature failure. It is therefore necessary to periodically inspect composite insulators so that any that become degraded can be replaced in a timely manner. Tradiitonally, the methods used to inspect in-service composite insulators have included:

• Acoustic emission

• Radio interference voltage (RIV) measurement

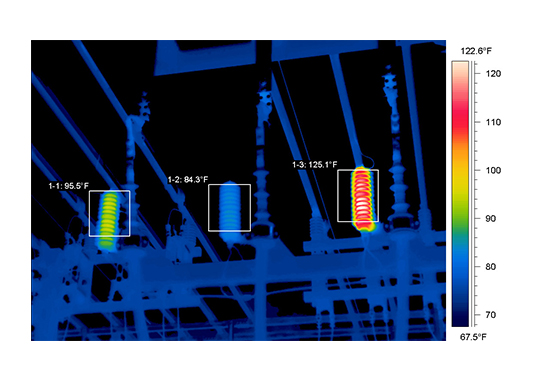

• Infra-red (IR) thermography

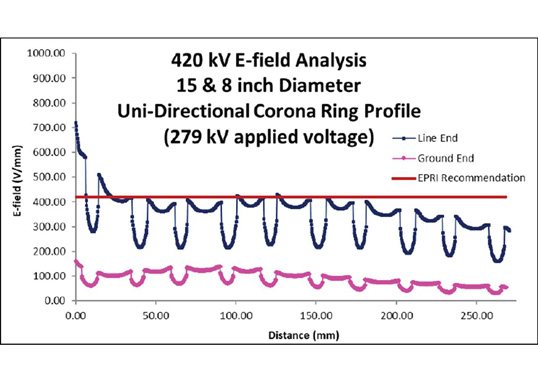

• Electric-field measurement

• Visual observation

CLICK TO ENLARGE

Both acoustic emission and radio interference voltage measurement methods are sensitive to background noise so cannot be used to determine the precise location of any discharge on an insulator. This is a significant drawback since discharges on insulator hardware cannot always be avoided and may not even pose a problem while discharges on the housing itself can be a harbinger to serious problems. Determination of surface temperature by IR thermography has yielded some success. However, this method cannot always detect minor defects that do not cause a significant rise in surface temperature. Reliability of IR thermography is also reduced when performed under hot or sunny conditions. Electric field measurement along an insulator has also been successfully used for both ceramic than composite insulators due to inherent differences in the construction of these insulators. But it has also been shown that this methodology can yield erroneous results in the presence of moisture. In addition, this method requires deployment from the tower or a bucket truck and hence is not always convenient. For these reasons, visual observation by trained personnel either from the ground or from helicopters has long remained one of the most common methods to inspect composite insulators.

Specialized cameras have long been available that detect corona in daytime and these are now regularly used by utilities during periodic line and substation inspections. Not only do they provide information on the exact location of corona but, due to their high sensitivity, some corona is seen on insulators quite frequently. When there is no information on the magnitude of the discharge it is difficult to base any decisions on insulator maintenance or replacement.

Principle of Operation of Corona Camera

Visual observation of corona with the unaided eye is difficult because corona emits weak radiation mostly in the ultra-violet (UV) spectral range, and is therefore invisible. The solar radiation in this region is much stronger than the corona thus masking corona signals. In the “solar-blind” region (240-280 nm), corona emission is much weaker. However, the solar background is negligible. It is these signals generated by corona in the solar-blind region that are used by the cameras to detect corona. The image captured is stored as a matrix of pixels and requires a number of processing and noise removal steps to facilitate mathematical operations and quantitative analysis.

Experimental Set-up

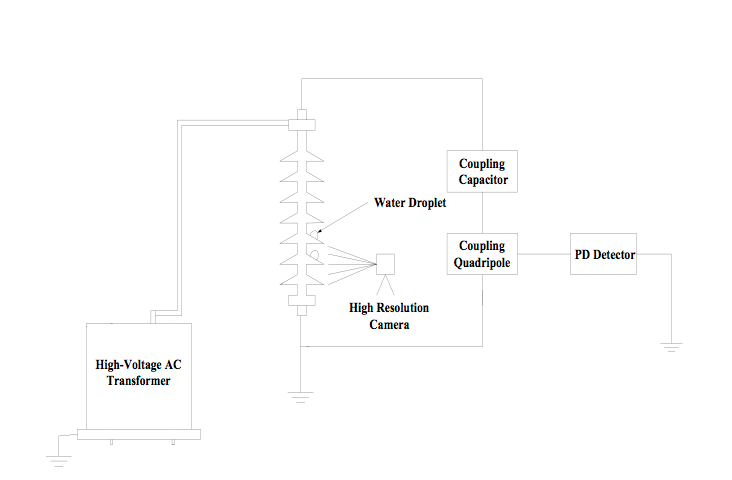

The experimental setup used in the present study is illustrated in Fig. 2. A 115 kV rated silicone rubber insulator removed from the field was chosen for the initial experiments. This insulator was selected because its line end fitting was unusually rough. The hardware also displayed burn marks caused by lightning events. The voltage applied was increased gradually to the rated voltage in steps of 5 kV. The corona images and their corresponding PD magnitudes were recorded simultaneously. For convenience, the distance between the point of interest and the camera was selected to be 5.

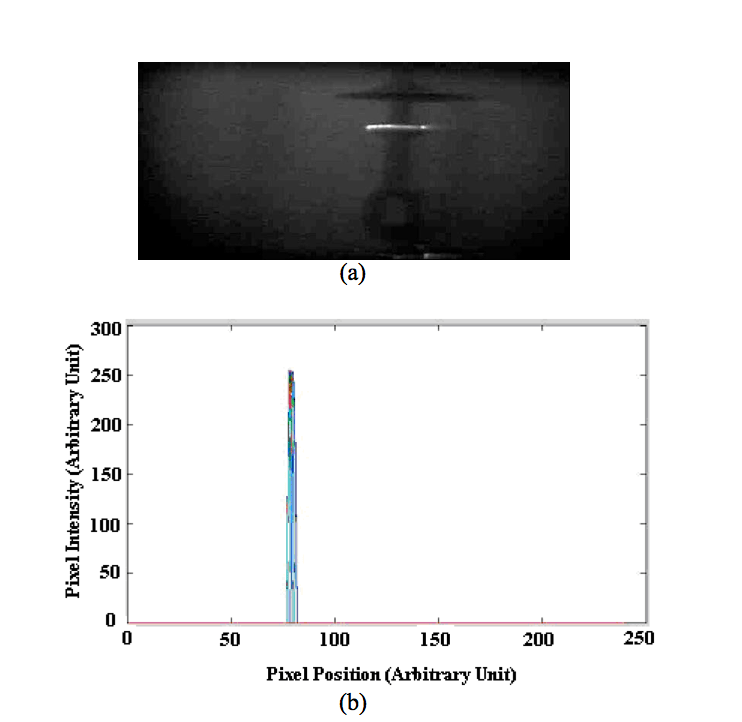

Any increase in the voltage from the inception value resulted in higher discharge magnitudes (measured by PD detector). Corona at 50 kV (0.75 p.u) of magnitude 30 pC from a weathered hardware of a silicone insulator under dry conditions and its corresponding intensity plot is shown in Fig. 3.

CLICK TO ENLARGE

CLICK TO ENLARGE

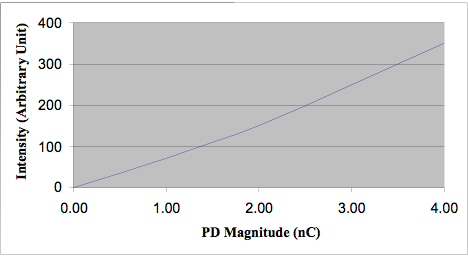

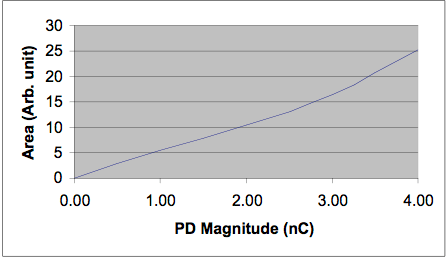

By changing the voltage in steps of 5 kV, the corona discharge magnitude was varied and the corresponding transformed parameter values were determined. Figs. 5 and 6 show the results of the transformed parameters as a function of the PD discharge magnitudes. The discharge magnitude associated with corona can be seen to be proportional to the intensity of the luminous discharge and the discharge area.

CLICK TO ENLARGE

CLICK TO ENLARGE

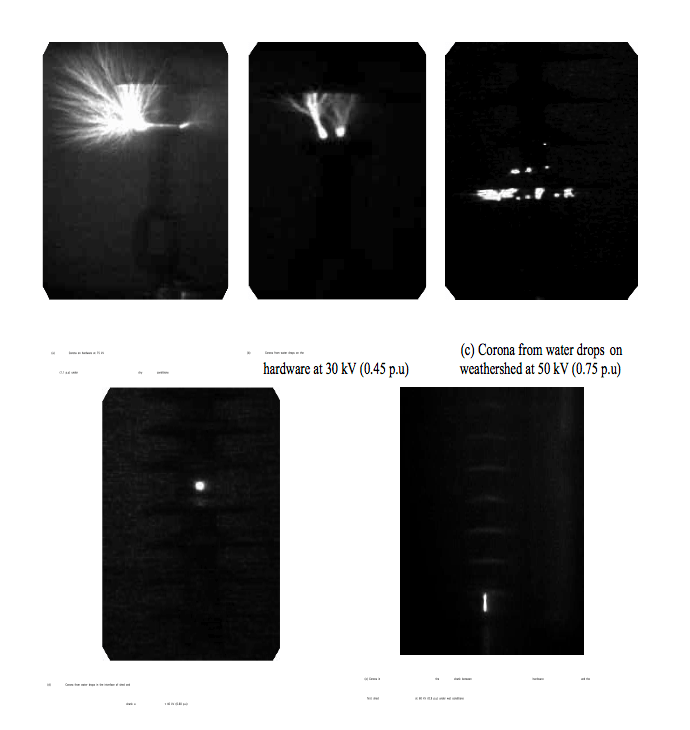

There are several regions in a composite type insulator that serve as preferential locations for corona discharges:

• hardware of the insulator even under dry conditions in the absence of a grading ring, as shown in Fig. 6(a).

• hardware and the hydrophobic housing material, especially in the presence of water droplets. This is shown in Figs. 6(b) and 6(c).

• interfaces created by joining individual sheds especially in the presence of water droplets. This is shown in Fig. 6(d).

• shank portion between high voltage end fitting and first shed especially under wet conditions, as shown in Fig. 6(e).

CLICK TO ENLARGE

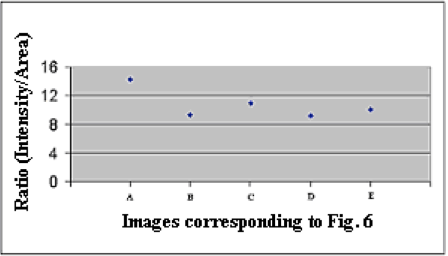

Knowledge of the discharge location is important. Discharges that occur on the hardware and/or far from the housing material are less damaging when compared to discharges that occur on or in close proximity to the housing. The ratio of the cumulative intensity to the area of the illuminated pixels is a measure of the corona discharge density and could be a good predictor of degradation. It might appear that the corona corresponding to images Figs. 6(d) and 6(e) has a less damaging effect than the corona corresponding to the image in Fig. 6(a). However, Fig. 7 indicates otherwise.

CLICK TO ENLARGE

Knowing the corona discharge magnitude is part of the problem. The other part is to determine the corona degradation characteristics of different housing materials. This aspect was explored in a past paper and the time for manifestation of damage from corona was determined for several composite insulator housing materials. Since this is dependent on formulation it is important to have this data in order to determine if the observed corona during field inspection is harmful to the insulator. Users need to create a database listing the discharge magnitude (or density) for every inspection. This will help establish if there are particular designs and field locations where corona can be more problematic than for others. Appropriate maintenance can therefore be performed in a timely manner.