[inline_ad_block]

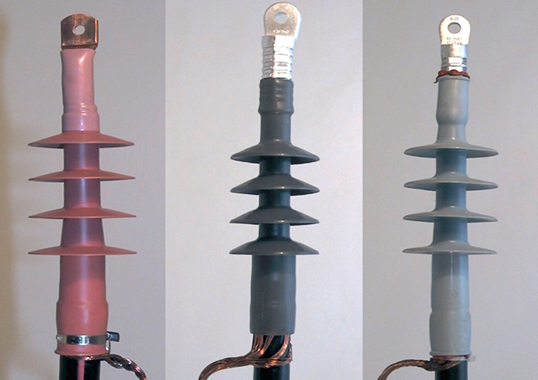

Most power engineers can claim to have seen the birth, development and in some ways maturing of insulator technology based on composite materials. More recently, there has been a new wave unfolding that involves use of composite materials for conductors. The term composite for both conductors and insulators is used rather loosely. Composite insulators are generally seen as those employing one kind of material for mechanical strength (i.e. the fiberglass core rod) and another material for electrical insulation under wet conditions (the polymeric housing). Similarly, the term composite conductor refers to types that use a composite material for the core to provide the mechanical strength required.

In point of fact, if examining the details of each component of a composite or even a ceramic insulator, these are not made from a single material but are actually a combination of several different materials. Nevertheless, the term composite is never used for traditional ceramic insulators. Similarly, composite is not used to describe conventional ACSR (aluminum conductor steel reinforced) conductors, wherein mechanical strength is provided by the central steel core while the current is carried by the outer aluminum conductors. Indeed, as with conventional conductors, composite conductors utilize aluminum strands on the outside for electrical conduction. The key difference lies in the materials used for the core.

There are different types of composite core materials available on the market – a ceramic alumina metal matrix composite and a carbon fiber glass resin-reinforced polymer. Given the huge sales potential, it is reasonable to expect that there will be new types of composite conductors and variations of these that evolve over time.

What are the drivers for this type of conductor?

Given increasing energy demand, utilities are looking at new ways to deliver more power on existing networks. Moreover, public opposition to new lines and increasing regulatory hurdles for these only make the option of delivering more power on existing corridors that much more attractive. Higher current in the conductor, however, means greater temperature rise due to conductor heating and therefore more sag. Presently, the upper limit of current that can be carried by many lines is limited by sag. Clearance to ground is reduced and this can violate national codes often determined by live-line working, induced electric field and other safety considerations. This limitation opens the door for new conductor technologies that promise to carry more current with lower temperature rise and sag than conventional conductors. This is achieved using materials with a reduced coefficient of thermal expansion as well as less weight than steel but with no corresponding reduction in mechanical strength. In principle, therefore, with existing right-of-ways and tower structures, utilities could deliver more power by simply replacing existing conductors with the new technology. These new conductors could operate at much higher temperatures (150-250° C) than is presently possible and effectively double current carrying capacity without violating sag or any other criteria.

Of course, making such a changeover would not be quite so simple. Utilities need to be convinced that the new types of conductors will last as long as conventional conductors and that they represent the best value proposition over the long-run. In this respect, there are lessons to be learned from experience with composite insulators in the area of accelerated testing and failure modes and which may prove applicable to composite conductors as well. One of these, for example, might be the philosophy of multi-stress ageing tests designed to simulate the effects of high temperature, moisture as well as chemical and mechanical stresses. There would also be a need to know about failure modes such as electrical tracking and mechanical fracture as well as the potential for brittle fracture. At the very least users would need to be convinced that these aspects have been examined in detail, probably even more so than has been the case for insulators. This is due to the fact that while an insulator life of 30 years is generally considered acceptable, utilities expect conductors to last far longer. Secondly, while an occasional failure of an insulator may be acceptable, failure of a conductor is definitely not since it has a far more serious impact on system reliability. Research has been performed over the years on important aspects of composite conductors. These include the role played by high temperature on mechanical performance of the core and the possibility of partial discharges in dielectric materials within the conductor. Also studied as been the role played by moisture and other chemicals that could be produced in the presence of electric field as well as failure mechanisms, residual life and more.

At the same time, there will be a need to ensure that the insulators and other hardware used with such high-temperature, low-sag (HTLS) conductors will retain their integrity under higher operating temperatures. For example, the most common type of end fitting employed in composite insulators is the crimped type, which is a compression type fitting. Subjecting existing hardware to higher operating temperatures would create thermal expansion that counteracts such compressive force. Different hardware may therefore be needed to ensure that composite insulators are not subjected to high temperature.

Prof. Ravi S. Gorur