Condition assessment of power transmission devices such cable systems is essential for their reliable operation. For example, diagnostics of oil-filled cables is important for transmission system operators to provide an indication of remaining lifetime. This aspect is also relevant for cable systems with extruded insulation. There are mature technologies that allow both continuous monitoring and also periodic assessment of the condition of a cable system. Temperature measurement on the cable surface and partial discharge sensors are examples of such monitoring systems and partial discharge measurements are established tools for condition assessment of cable accessories as well. Most outdoor terminations these days are filled with an insulating fluid, typically silicone oil, and a diagnostic of this fluid therefore offers another means of overall assessment, apart from PD measurement. The key parameters in this regard are moisture content, dielectric properties and dissolved gases. This edited past contribution to INMR by Brugg Cables in Switzerland described methods to assess terminations used on cables with extruded insulation and which are the interfaces to other components of the power grid. These can be classified into indoor terminations for connection with transformers and gas-insulated switchgear or outdoor terminations for connection to an overhead line or switchyard.

Design of Fluid-Filled Outdoor Terminations

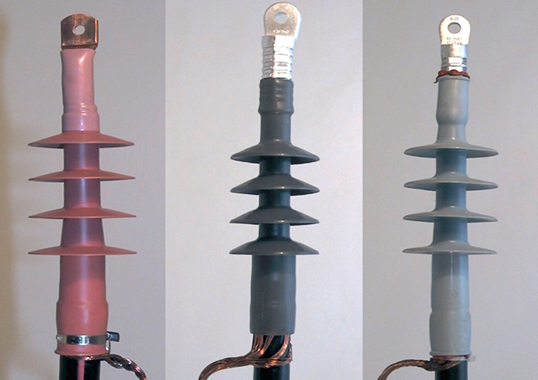

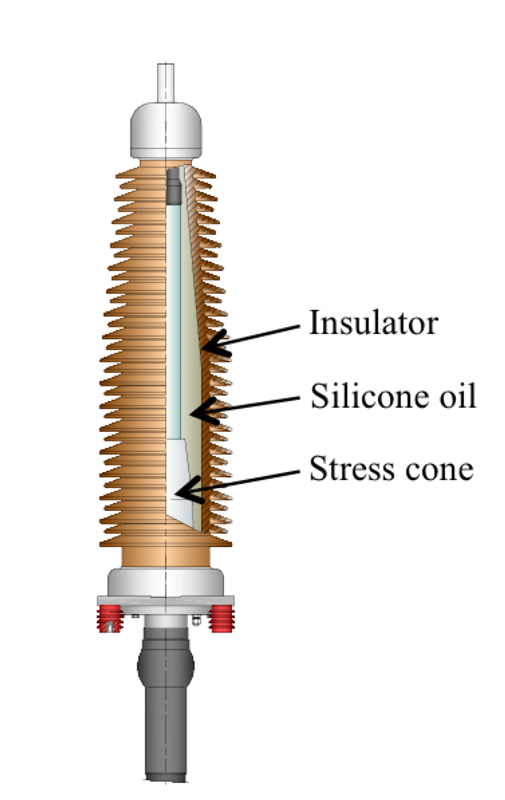

A typical fluid filled outdoor cable termination is shown in Fig. 1. Much the same design is used for voltages Un = 60 kV to 500 kV. The main component of this accessory is the stress control element, which uses a semi-conductive electrode made of silicone rubber or EPDM for geometric field grading. The outer insulator can be porcelain or a composite housing, depending on customer preference.

As mentioned, silicone oil is the main insulating fluid in use these days. A certain chain length of silicone molecules is necessary to avoid migration into the silicone rubber of the stress cone. The consequence is a relatively high viscosity if the stress cone is made from silicone. But there are also terminations still under operation that are filled with mineral oil in spite of the fact that environmental impact of leaks has caused the shift in technology towards the silicone oil, which is also non-flammable.

Analysis of Dissolved Gases

Dissolved gas analysis (DGA) is a well-established technology for assessing condition of power transformers and also widely used for evaluation of old oil-filled paper (LPOF) type cables. In both cases, the insulating fluid is typically mineral oil, as also used in the past in outdoor terminations for extruded high voltage cable. The aim of a DGA is detection of partial discharges in the insulating medium so as to prevent failure of the termination. Hot spots that can sometimes occur in power transformers are highly unusual in a termination since any heat losses can easily be removed due to the large surface area relative to oil volume. The basic procedure in a dissolved gas analysis consists of the following:

• Taking sample from the termination;

• Extracting the gas from the oil;

• Analysing the gas sample by computer tomography;

• Interpreting findings according to manufacturer guidelines.

Convective flow causes a homogenous mixture of the oil during operation and a sample taken from the lower base plate of the termination can be therefore be regarded as representative. Sampling using a probe is theoretically possible during service but typically has to be done offline for reasons of safety. It is obviously important to avoid any contamination of the sample. There are a number of possible procedures for extracting gases from the oil and each procedure might yield somewhat different results. As a result, it is recommended to always use the same laboratory. Moreover, what is also important in such assessment, apart from absolute value, is the trend.

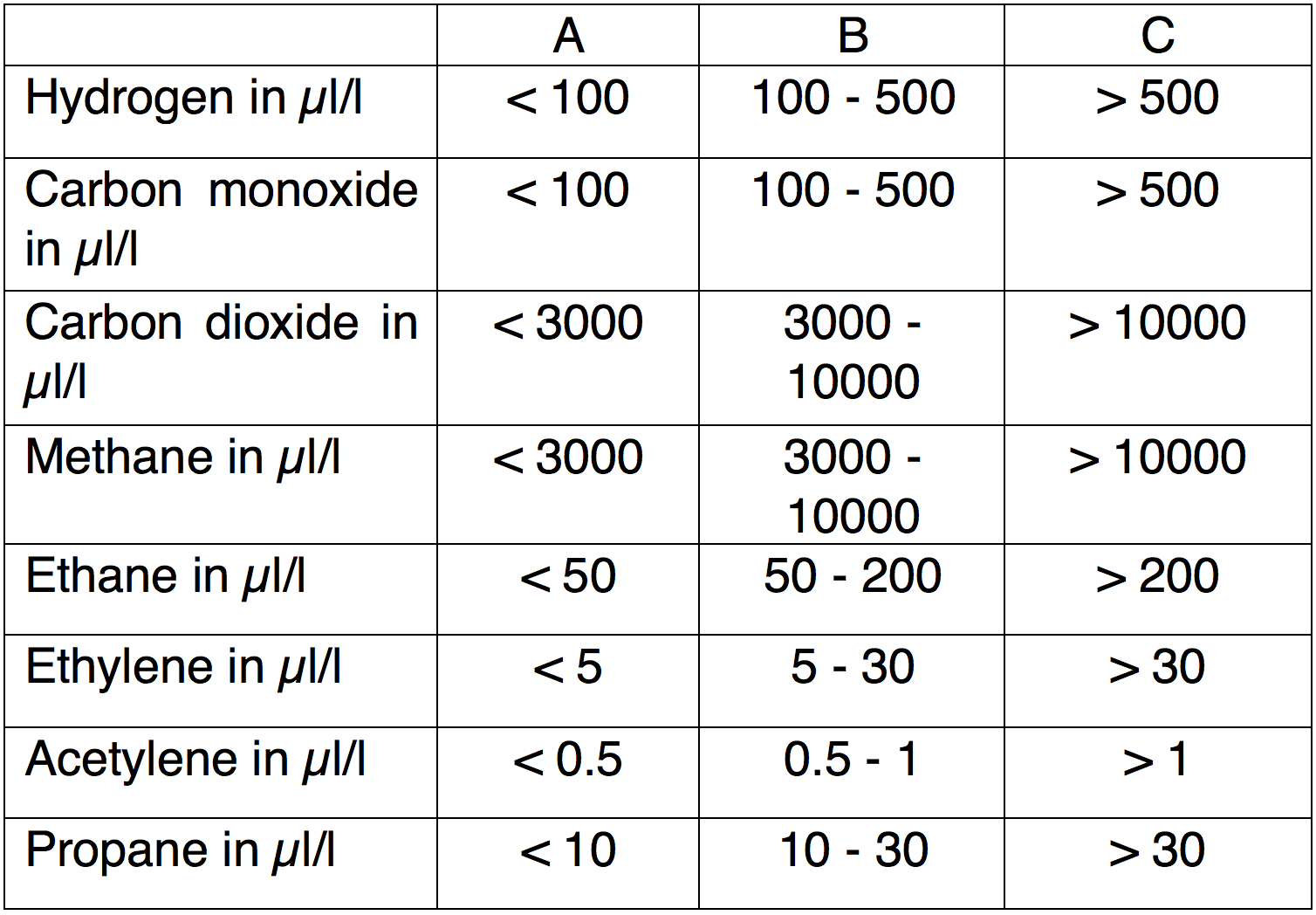

There is no standard available that could be used for interpretation of results. Therefore, the experience of the accessory manufacturer is necessary to properly assess fluid condition based on gas content. The limits, given in Table 1 are based on such experience and are classified into A, B and C. As long as gas content stays below the values in A, no further maintenance action is required. Findings in the range of B, suggest that further tests or a repetition of testing after a shorter than normal interval are recommended. Reaching the limits given in C generally implies that immediate action must be taken.

The main gases for such evaluation are hydrogen (H2) and acetylene ethyne (C2H2). H2 indicates that partial discharges of low energy are occurring inside the termination. If C2H2 is detected as well, it could be concluded that there have been partial discharges of higher energy or even some electric arcing taking place inside the fluid. The presence of methane and propane are further indicators of internal electrical activity in the insulating fluid, mainly in relation to the mineral oil in an oil-filled cable or transformer. However, evaluating the condition of a termination on a polymeric XLPE cable is not always possible due to the fact that both of these gases are generated during cable production as by-products of the cross-linking process. These gases could therefore remain in the insulation if the cable is not properly de-gassed after extrusion and migrate during operation into the insulating fluid of the termination.

While partial discharge measurement provides only a momentary view of electrical activity of a termination, DGA is a representation of the previous service history of the termination. Such measurement therefore provides an indication if and to what extent electrical activity has occurred inside the termination. In any case, analysis of dissolved gases allows no localization of failure inside the termination. As long as only discharges are occurring, the termination will not fail during a subsequent short time interval.

First testing of terminations could be done 12 to 24 months after system energization but assessment during operation might be deemed necessary if there any concerns due to certain events, such as failure of a termination on a neighbouring phase in the system. External events such as high pollution level accumulating on the surface of the termination is another reason for more immediate condition assessment. Manufacturers typically recommend repetition of DGA every 2 to 5 years, with the specific interval selected depending on service environment. Of course, a shorter time frame between successive tests will allow better understanding of any possible trends. It is also important is to define beforehand what remedial actions are to be taken if certain limits have been reached.

Evaluation of Moisture Level Inside Termination

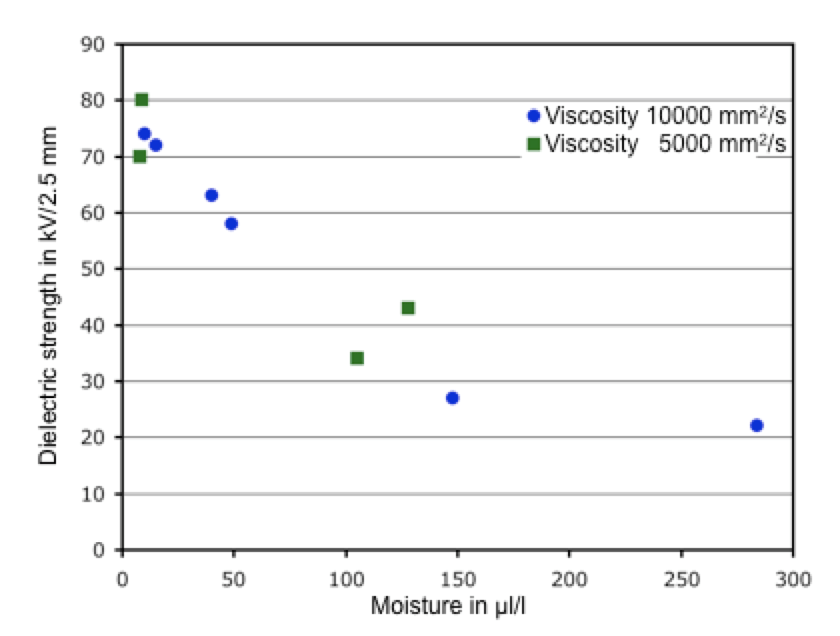

Any moisture present in silicone oil will decrease its dielectric strength. Fig. 2, for example, shows this dependence for two different silicone oils.

From this chart, it is clear that dielectric strength decreases dramatically above a concentration of 100 ppm. Based on these results as well as service experience, manufacturers therefore have defined a limit of 90 ppm, which is significantly higher than for new oil.

Moisture ingress is typically due to improper sealing. Leaks could also be caused by damaged components or by errors during installation error and are one of the main reasons requiring maintenance intervention on a termination. Measurement of moisture content in the insulating oil of a termination is a relatively easy diagnostic tool since only small samples are needed. Assessment is then also faster for evaluation of the breakdown voltage of the sample.

Case Histories from Service

Two case histories are presented here to illustrate manufacturer experience in diagnostics of fluid-filled terminations. In both cases, moisture content was determined and a DGA performed. The first involved assessment of a 420 kV termination installed in gas-insulated switchgear (GIS), as shown in Fig. 3. These kinds of terminations are typically completely filled with silicone oil and also equipped with a vessel that compensates for expansion of the silicone oil.

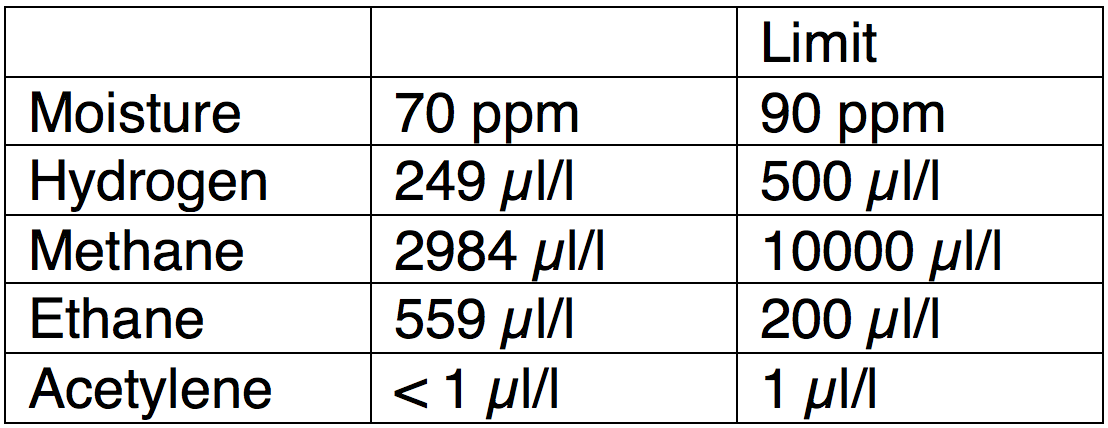

Evaluation of the silicone oil was performed because the termination was flagged during a PD-test and results of the analysis are given in Table 2.

Moisture content was found to be higher than expected for a newly installed termination, even if below the limit. The ratio of methane and ethane formed during cross-linking of XLPE-insulation is approximately 10 to 100 but in this case the ratio was different. This suggested that the relatively high ethane content in combination with the hydrogen present was caused by discharges in the silicone oil. The assessment eventually led to the conclusion that the termination had to be visually inspected and the unit, with insulator removed, is shown in Fig. 4. A yellow jelly-like material was seen on the upper part of the termination and this residue of aged silicone oil was caused by electrical discharges in the oil. Since the cable core was affected only on the surface, it was possible to simply clean it as the necessary remedial action. This result allowed re-assembly of the original termination and an outage of the termination was thus avoided with only minimal testing.

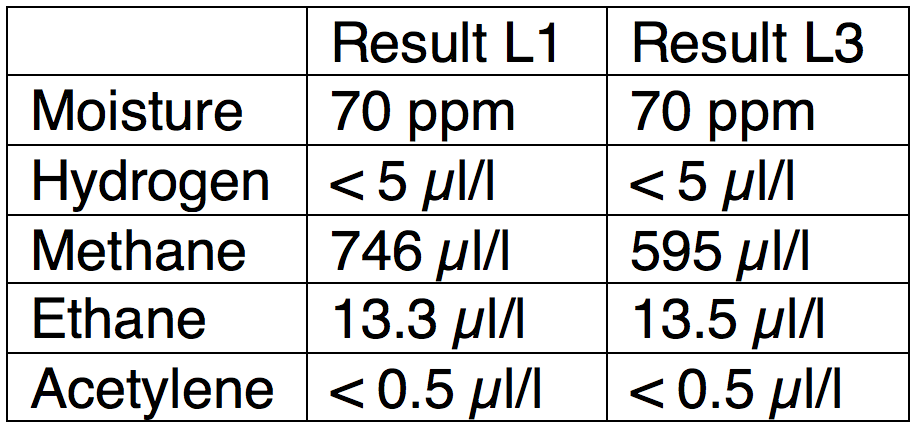

In the second example, a termination failed during service. Based on this, the insulating medium of the two remaining terminations (Phase L1 and Phase L2) were evaluated to detect whether or not partial discharges had occurred. For this reason, dissolved gases and moisture content of the silicone oil were assessed, with results shown in Table 3.

These results showed that there was some moisture but below the limits provided in Table 1. While some methane and ethane were also detected, concentration of the two main diagnostic indicators – hydrogen and acetylene – was below their upper limit. Due to this, both terminations could be assumed to be free of partial discharges inside their oil.

Conclusions

Periodic evaluation of the condition of fluid filled terminations should be an essential part of any preventive maintenance strategy for cable systems. The reasonable time interval for this will depend greatly on the environmental conditions of the termination. There are proven diagnostic tools that allow both manufacturers and users of high voltage accessories to perform reliable assessments of their terminations. Determination of moisture content is a major element of evaluating condition of a fluid filled termination while an additional diagnostic tool is analysis of dissolved gases.

It has been shown that there are two key gases that allow reliable assessment of the operating condition of an outdoor termination. Hydrogen (H2) shows partial discharges of low energy but should acetylene (C2H2) also be found in the oil, it could be concluded that discharges of high energy are occurring. Visual inspection is recommended in such a case. Evaluations of terminations performed on site have confirmed that dissolved gas analysis delivers reliable results.