Application of Station Posts by Jens Seifert/Eric Moal

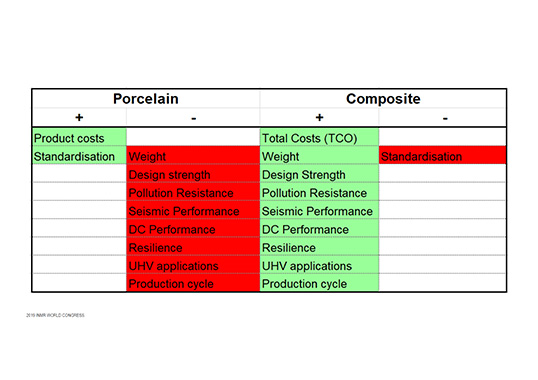

Station post insulators are indispensable for HV substations and related apparatus. Porcelain station posts have been applied for more than 100 years, with voltages ranging from 1 to 765 (800) kV and maximum cantilever strengths from 20 to 30 kN. Single units can be manufactured to a length of 3000 mm while, for voltages over 245 kV, assemblies consist of 2 or more units connected by flanges. Modern production technologies offer high-strength designs optimized in shape, weight and shed profile. Glass station posts, by contrast, consist of individual units assembled by cement and complex profiles can be realized. For severe pollution conditions, RTV coatings improve electrical performance. The first composite station posts were introduced in the 1980s, consisting of solid core fiber reinforced polymeric core material with an elastomeric housing. Typical core diameters are 45 to 100 mm with maximum diameters rarely exceeding 130 mm. For voltage classes over 245 kV, given increased bending moment, much effort is needed to meet requirements with solid core designs. Composite hollow core station posts as well as hybrid station posts have begun filling these applications, with the former already realized up to 800 kV HVDC and 1100 kV UHV and with connection lengths of more than 10 m. This presentation reviews the state-of-the-art of these alternative technologies, related standards and ideal applications for each. An outlook is also made to future applications where use of composite station post insulators will be preferred.