Ageing of Polymer Insulators by Fabio Bologna

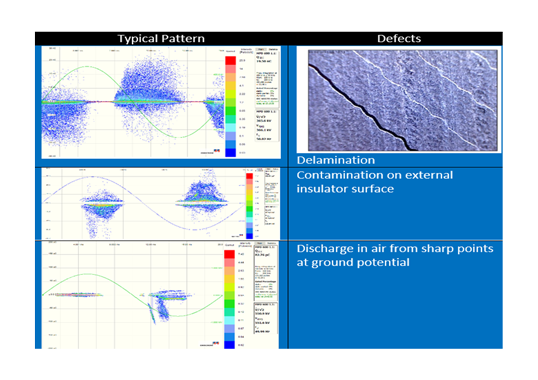

Polymeric transmission line insulators mechanically support the conductor above ground and electrically the conductor from the grounded structure and if they fail either a transmission outage results. Most reported failures of polymeric suspension insulators are from brittle fracture or flashunder, with both occurring if moisture ingresses past the rubber weathershed or end fitting sealant and contacts the fiber reinforced plastic core. Such in-service damage is usually associated with electrical stressors such as leakage current, corona and flashover while other types of damage can be due to handling and in some cases wildlife. EPRI performed full-scale multi-stress accelerated ageing on polymeric insulators to understand modes of weathershed degradation and results have correlated with failures observed in the field. Primary stressors are corona discharges from end fittings as well as from water drops. While it is recommended to keep E-field magnitudes below corona discharge extinction levels, discharges still occur due to uncontrollable factors and, in these cases, the weathershed must be able to endure them. Testing insulators under full-scale conditions is costly, time-consuming and difficult to use during selection and procurement. As such, representative, repeatable and cost effective tests to evaluate performance need to be developed to enable selecting and procuring polymeric insulators that provide optimum life expectancy and performance. This presentation discusses a small-scale, corona-ageing test on an insulator sheath that meets this need and can be included in utility specifications.