Not long ago, Denmark became the first country where the ubiquitous lattice transmission tower was no longer accepted for any new power line construction. While relatively small and with a population of less than 6 million, what made this development noteworthy on the international stage was that Denmark was a frontrunner in a trend that has been impacting a growing list of countries – public opposition to new overhead lines. Indeed, the lattice tower has become a symbol of the blemish that overhead lines sometimes impose on natural landscapes. If power companies can find more aesthetic and less obtrusive structures, there is good reason to expect that the public will object less, if at all.

Several years ago, INMR visited one of the recent alternatives to lattice towers and met with the industrial designers who developed the concept as well as with the transmission system operator who made use of it. Apart from a valuable case history on how to make new transmission lines more acceptable to a wary public, this article also offered insight into the application of insulators for these types of projects.

The origins of the double circuit 400 kV Kassø-Tejle line that runs northward along the Jutland Peninsula lay in the goal of strengthening the interconnection between Germany and Denmark, and from there to Norway and Sweden. However, realizing this goal by means of another overhead line required overcoming strong objections by those who lived in this flat region of small farms and historic towns. Energinet, the Danish grid operator, first began planning the line back in March 2009 with an environmental impact assessment, as required by regional planning authorities. This document proposed that the initial route for the new line would be aligned as much as possible with a pre-existing transmission line between the two points. The first public planning took place in June that year and Energinet was asked to study different routes in terms of expected effect on people, buildings as well as local wildlife and vegetation. Within 3 months, these alternatives were set out, each with a 400 meter wide planning zone.

A second pubic hearing for the project took place between March and May 2010 during which the environmental impact assessment was published and the public was given a time frame to express their views as well as any proposals for adjustments. By autumn of that year, the final environmental impact assessment and detailed route planning had both been reviewed and within 6 months negotiations began in regard to compensating affected landowners. Construction of the line began at start of 2013, with the project scheduled to be completed by November 2014.

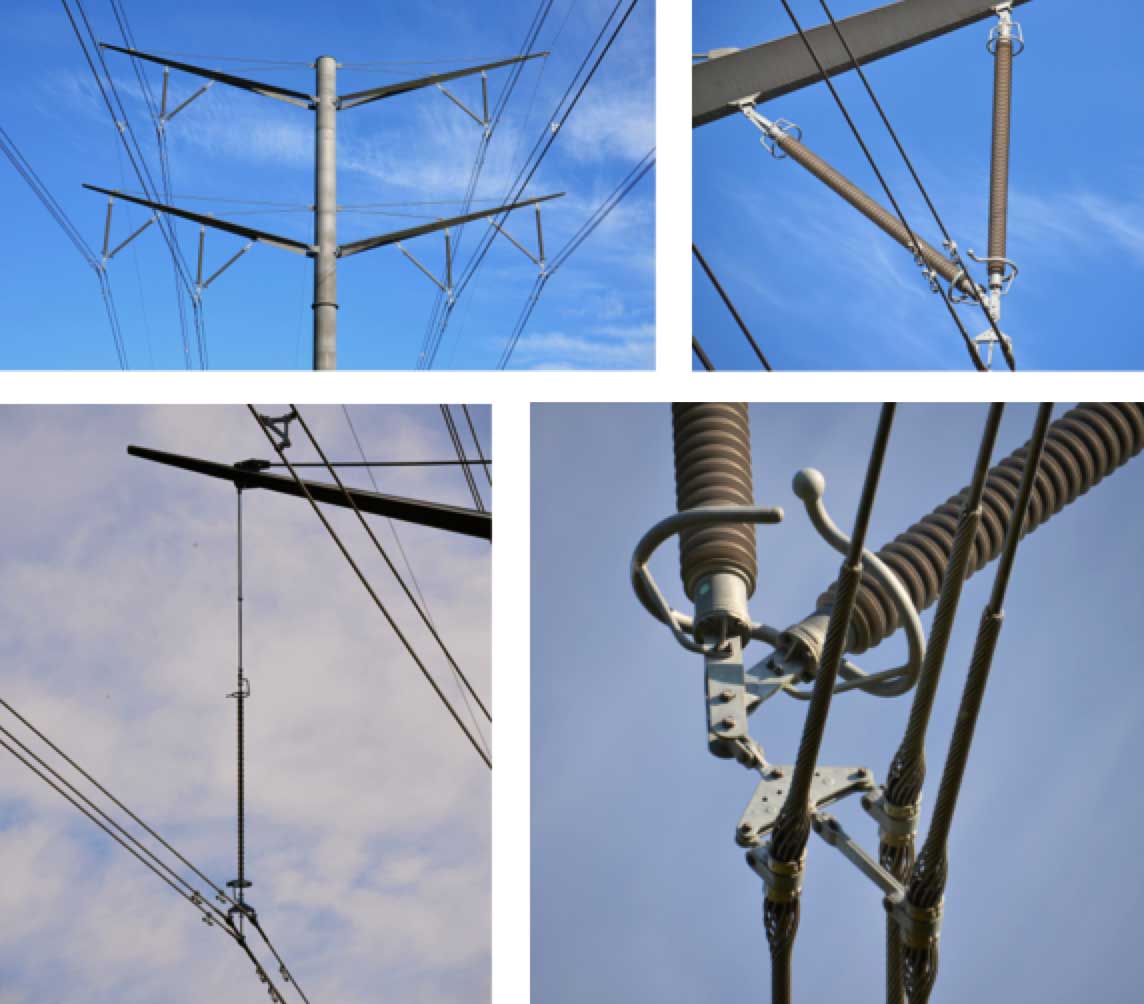

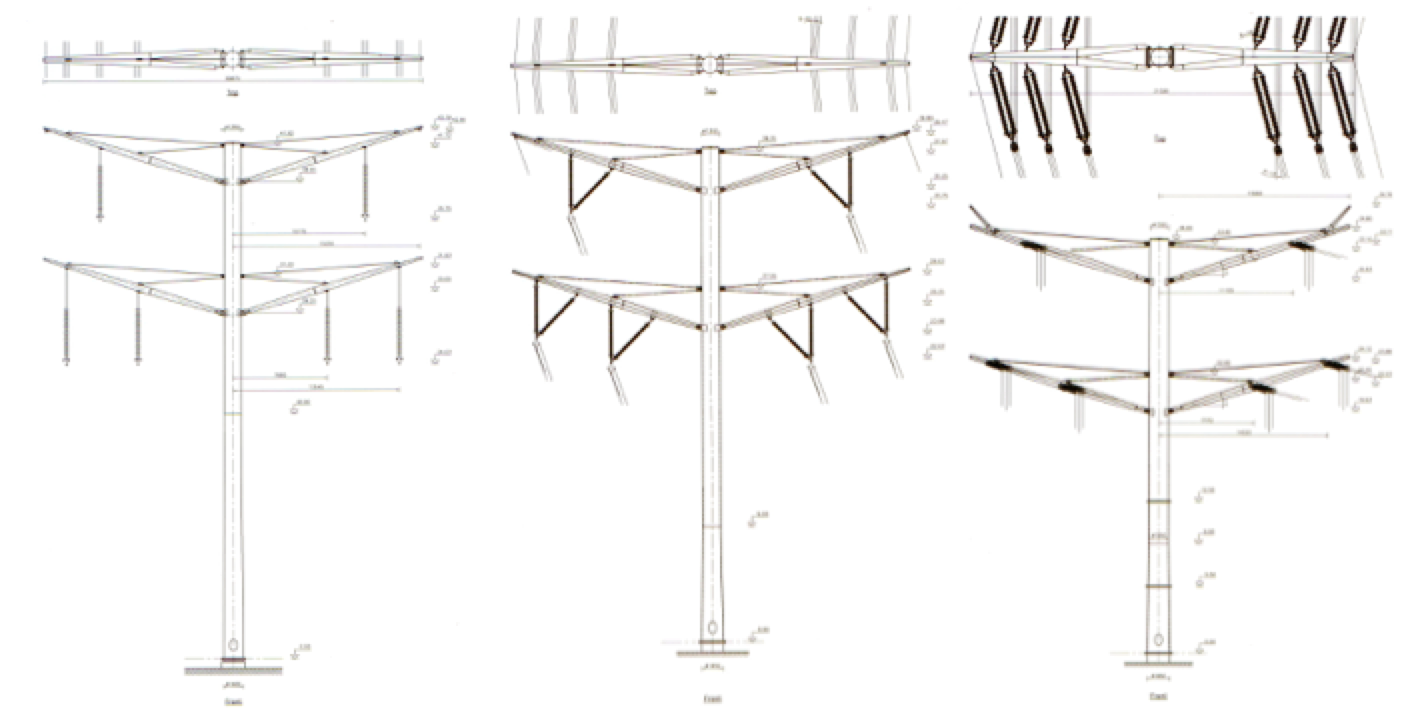

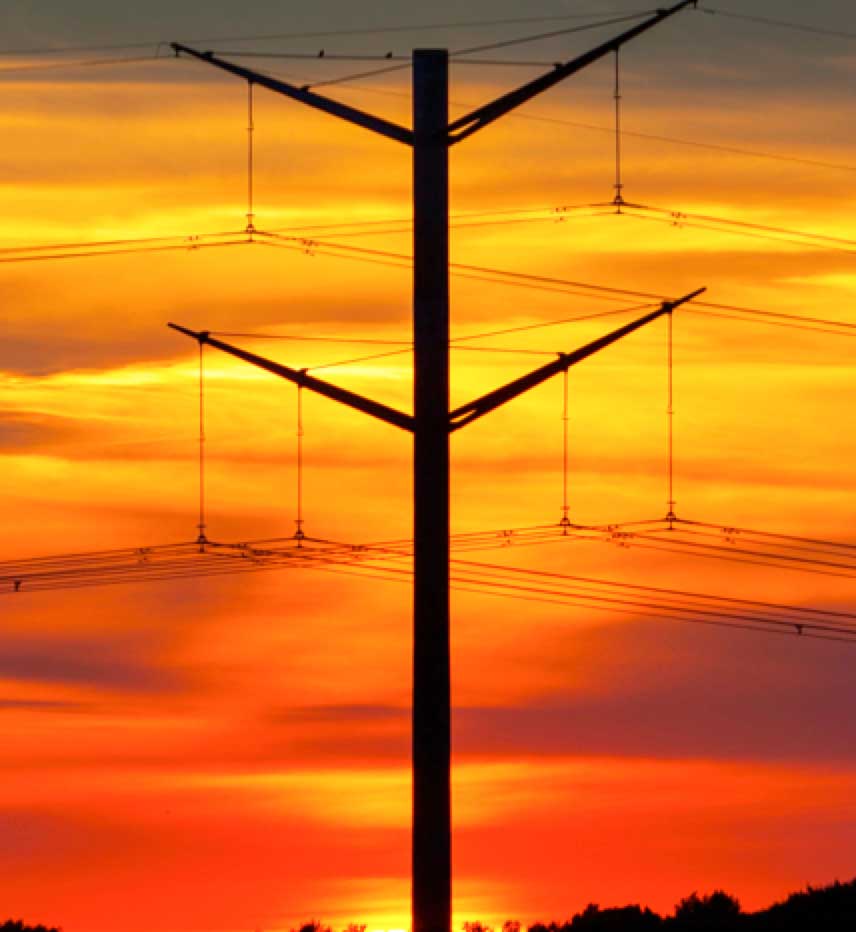

The Eagle Pylon selected for the Kassø-Tejle Project was a design concept developed to convey calm and elegance in order to best blend a 400 kV transmission line into a scenic rural landscape. The tower finally selected was based on a hot-galvanized cylindrical steel shaft and rhombus shaped cross-arms and represented a departure from what was originally proposed – a weathering steel alloy that among other ingredients contains a small percentage of copper. There is rapid formation of an outer ‘skin’ on such masts that quickly stabilizes against further oxidation, thereby giving the structure a virtually indefinite lifespan.

Cost-wise, the alternatives of hot galvanizing versus copper steel alloy without galvanization were found similar. But from a sustainability point of view, the copper steel solution was deemed preferable since zinc from the galvanized layer could leech down over the years and contaminate soil. Still, in this case local farmers did not want something on their land that looked rusty.

>Another point of departure from the original concept was use of two cross-arms instead of a single long one to support all conductors. The decision here was also made by local landowners and based largely on how far away structures could be sited from existing homes. Going with two cross-arms in place of one increased the amount of steel and cost of each structure by about a third. Yet in the end the decision was not financial but aimed at satisfying local preferences. A single cross-arm would also have allowed reducing the height of the mast.

Engineers at Energinet who were involved in planning the Kassø-Tejle line, explained that the policy adopted in Denmark since 2007 is that all transmission lines less than 400 kV must be placed underground. Moreover, while overhead 400 kV lines are still permitted, these must now be based on single pole structures. The cost premium of burying lines has been estimated in Denmark at some 3 to 4 times higher than overhead lines although experts in other countries claim this factor is closer to from 6 to 12. At the same time, transitioning from overhead to buried lines can often prove a challenge, both technically as economically. Designing aesthetic power structures is therefore something that will remain important because replacing all overhead transmission lines by cable is not yet feasible nor likely to be so anytime in the near future.

Notwithstanding differing opinions on the future of cables versus aesthetic overhead lines, the new Kassø-Tejle line was nonetheless placed underground at three environmentally sensitive points along its 166 km route. This approach had been taken elsewhere in Denmark and also in the Netherlands, where the first 380 kV Wintrack line features a 10 km section of cable near the historic city of Delft.

Transitions from overhead line to cable can prove more disruptive, both environmentally and aesthetically, versus simply continuing an overhead line without interruption. This is because going underground requires a transition station filled with structures and equipment that can cover an area the size of a football field. The same occurs at the other end while, in-between, is a beautiful town or valley. From a purely aesthetic point of view, designers in Denmark feel that there would be less environmental impact from simply letting the line run uninterrupted. In fact, if anything, such changes only add disorder and a messy overall appearance by breaking continuity.

The same reasoning also applies to deviations in a line around so-called ‘environmentally safe’ zones. Any such route deviations can cause a line to zigzag unnecessarily and destroy the alignment of structures that can be as important as the aesthetics of individual towers. In other words, to create maximum calmness when adding a transmission line to any environment, all structures have to be organized. It is not sufficient just create beautiful structures.

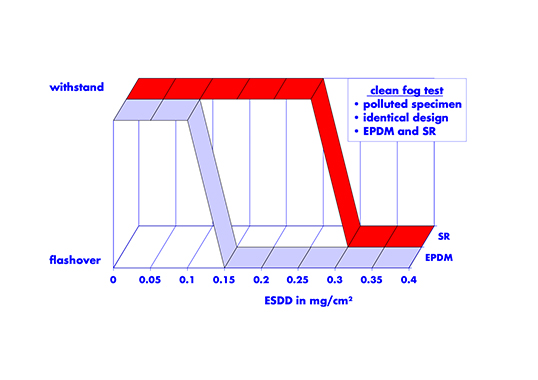

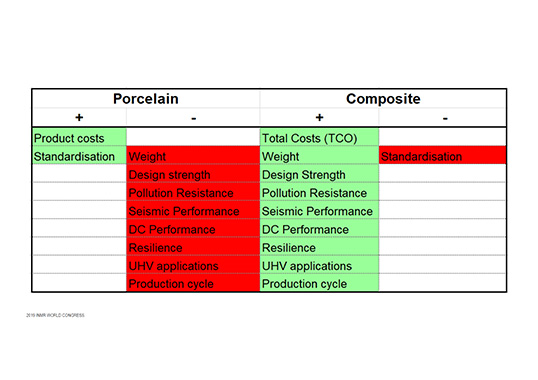

One of the interesting features of the line was selection of only composite type insulators for all of its more than 500 structures. This decision represented a departure for Energinet, which until that point has relied almost exclusively on glass insulator strings. However, while glass strings could have worked on suspension towers, the flying angle type of tower design could not succeed well with glass because it combines both tension and compression loading – something that is difficult to achieve with glass – especially for insulators angled at 45°.

For example, flying angle structures for route adjustments of from 4° to 10° along the line employ a matching pair of silicone insulators with 120 mm core rods to handle all tensile and compressive forces. According to engineers, this was actually good thinking when it comes to aesthetic line design because the conductor is fixed in place with exactly the same configuration of insulators in every case, including on angle towers. Typical past angle towers without such an insulator arrangement would have had to be moved out of alignment to compensate for the outswing of insulators which must align with the route. By contrast, these new towers could be sited in perfect alignment because the conductor position is held fixed by the V-string.

To achieve better appearance near a GIS switching station near the town of Vejen, three small angle structures were chosen instead of one tension tower since such towers, with their jumpers, can prove visually disturbing. Also, while the tension insulator for each V configuration on flying angle towers could have had smaller diameter rod due to less need for mechanical strength, Energinet wanted the two to be identical to achieve the best visual impact. The arcing distance of 3.2 m and total creepage of 12 m selected for these insulators was chosen to be the same as normally specified for glass strings operating in a low contamination area, even though less specific creepage could have been specified for insulators made with silicone.

Another issue when it came to insulator selection was reducing noise, which also favored using composite types based on information from suppliers. Indeed, to keep audible noise levels along the route as low as possible, Energinet also chose a three-conductor bundle when a duplex arrangement would have been sufficient to handle the load. Adding a third conductor represented an additional investment, but these types of choices were governed by making the line as acceptable as possible to local communities – not by finding ways to control costs.

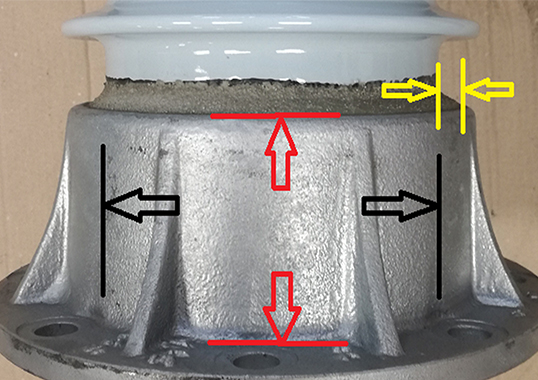

Construction of the new 400 kV line was assisted by the decision to use steel tube foundations, each equipped with a protective cement collar to protect the steel against water and passing farm machinery. This decision not only reduced typical foundation costs but also the time subsequently needed to erect each tower. For example, such foundations can be hammered into the ground in only about 30 minutes. Then, following a standard procedure where all tower parts are laid out in advance in the field, the time needed to erect each structure averaged only one day per team.

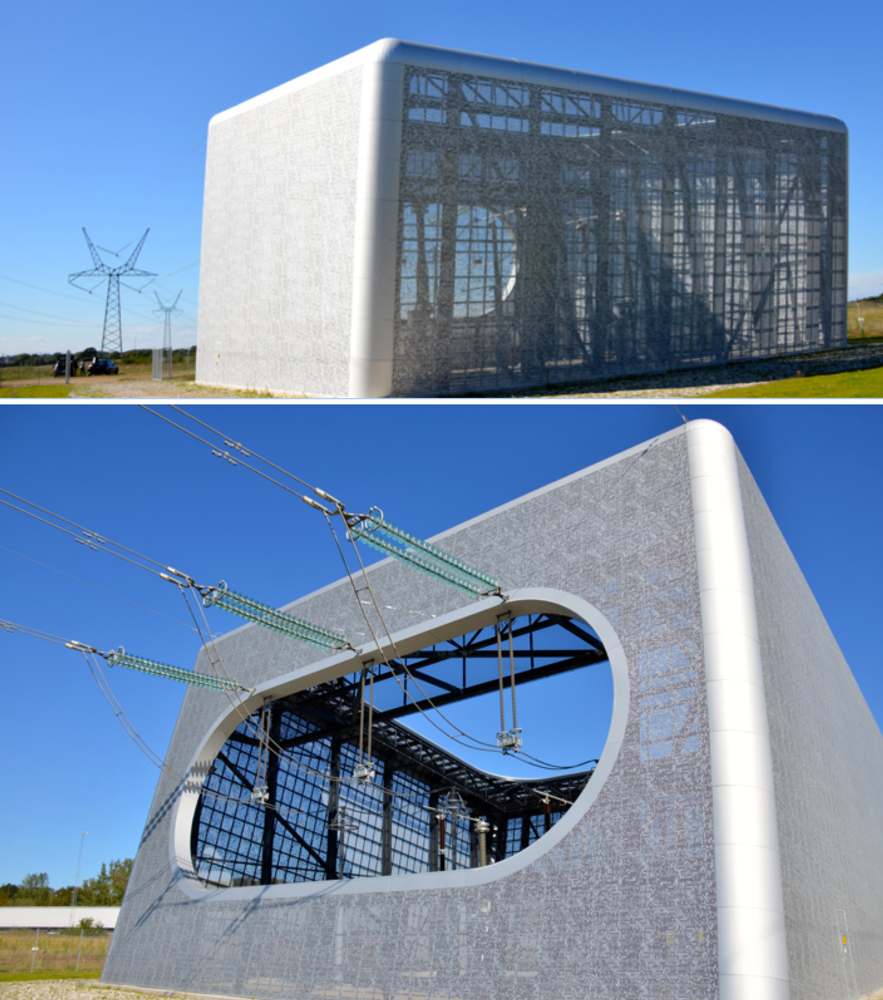

The policy regarding prohibition of new lattice power structures adopted in Denmark has been trigger for several related projects by Energinet, apart from the aesthetic Kassø-Tejle line. For example, four 120 m high lattice towers that carried two 400 kV circuits from Jutland to the nearby island of Fyn since the 1970s were dismantled in 2014 and replaced by a subsea cable. On the Jutland side of the new link, two cable transition substations were completed and housed in a futuristic enclosure made of steel plate containing holes. Cable terminations at these stations, like most normally used tby Energinet at 400 kV, are silicone housed and oil-filled.

A number of lessons were learned from the experience of this line that could apply to any new single pole line going up in the world – including the 400 kV T-Pylon design developed for the grid operator in the U.K. One of these lessons was that the overall cost of each aesthetic tower is not as prohibitive as some imagine at the start. While Energinet estimated that each Eagle pylon came with a 30 to 40 percent cost premium versus the banned lattice steel tower, it was only marginally higher if looking at total installed cost. In fact, considering the large savings realized on foundations as well as faster erection times, this line would have been close to the same cost as traditional structures if the single cross-arm original design concept had been chosen. Another lesson was that final design of aesthetic lines should not be dictated only by those who may live nearby or might own the land on which towers are sited. Affected landowners should not be the only ones who decide how power lines will look since the landscape belongs to everyone.