Advantages of Silicones in T&D Applications by Andrei Szabo

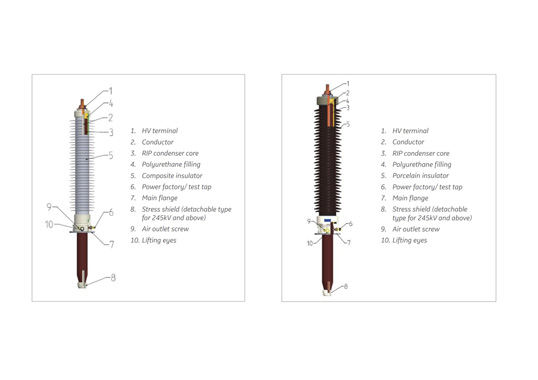

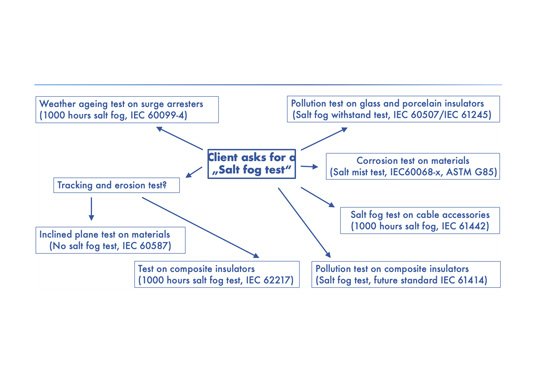

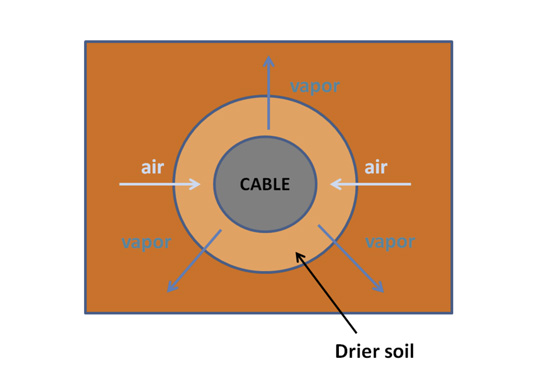

Silicone polymers are a class of versatile inorganic materials suitable for the needs of a broad variety of industries and whose unique properties perfectly fit requirements in the T&D industry. Indeed, silicone rubbers, fluids and gels are increasingly used in power industry applications that pose different challenges for materials in regard to processing method as well as mechanical and electrical characteristics. Beneficial properties offered include hydrophobicity and hydrophobicity transfer, less or no need for maintenance, light weight of finished parts, resistance to weathering, ozone and radiation, flame retardant properties, high arcing, tracking and thermal resistance and excellent dielectric properties. Among the components that benefit from these properties are rod and hollow core composite insulators and arresters for medium, high and ultra high voltages, RTV-coated porcelain and glass insulators as well as high-tech cable accessories and fire safe cables. This presentation reviews what has been learned from 100 years of experience as a manufacturer serving the needs of the T&D community with a growing portfolio of silicone solutions for reliable power supply.