Asset owners have become concerned in recent years that polymeric materials used in outdoor insulation may be more prone to biological growths than ceramic materials and that certain polymers might be more affected than others. The focus of such concern relates to the potential impact of biofilm on insulator performance. In the case of ceramic insulators, for example, reports of biological growths based on experience in tropical and subtropical environments has suggested substantial reduction in wet flashover voltage (i.e. from 25 to 70%) due to presence of biofilms. It has also been noted that sections of insulator glaze can be damaged by acid released by algae. In the case of non-ceramic insulators, experience in tropical environments showed that reduction of wet flashover voltage due to biofouling could be as high as 35%.

Nevertheless, in spite of these findings, review of literature on this topic has shown that there has never been direct comparison of the relative impact of biofilms on different insulation materials conducted under identical service conditions. This edited past contribution to INMR by Sung-Woo Cho of the Royal Institute of Technology in Sweden as well as Henrik Hillborg and Lars Jonsson of Hitachi Energy reviewed results of research aimed at documenting and comparing the relative impact of biological growths on performance of polymeric as well as ceramic HV insulators.

Research Methodology

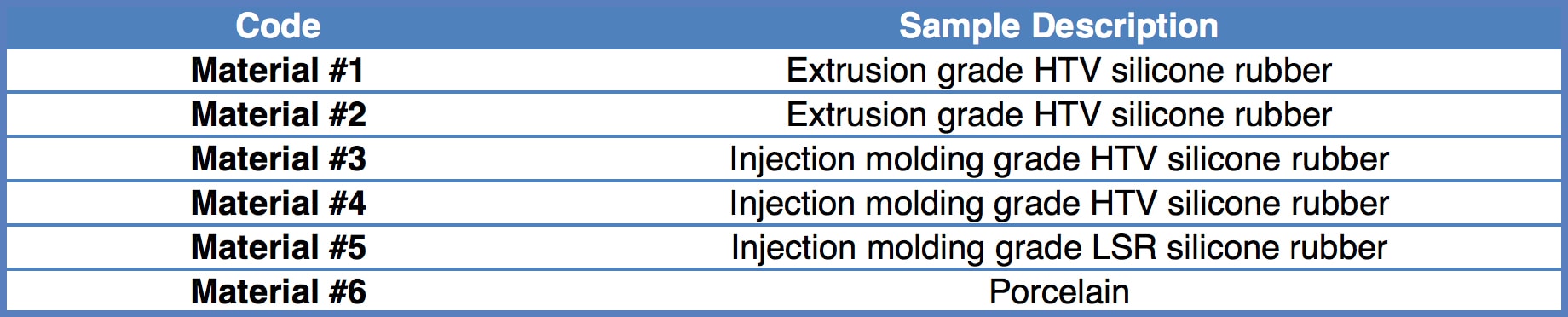

Table 1 outlines the polymeric insulator materials studied in this project, which included four different formulations of High Temperature Vulcanized (HTV) silicone rubber and one type of Liquid Silicone Rubber (LSR). Porcelain served as the ceramic material under test.

(*Taken from New Insulators Never Exposed to Outdoor Environments)

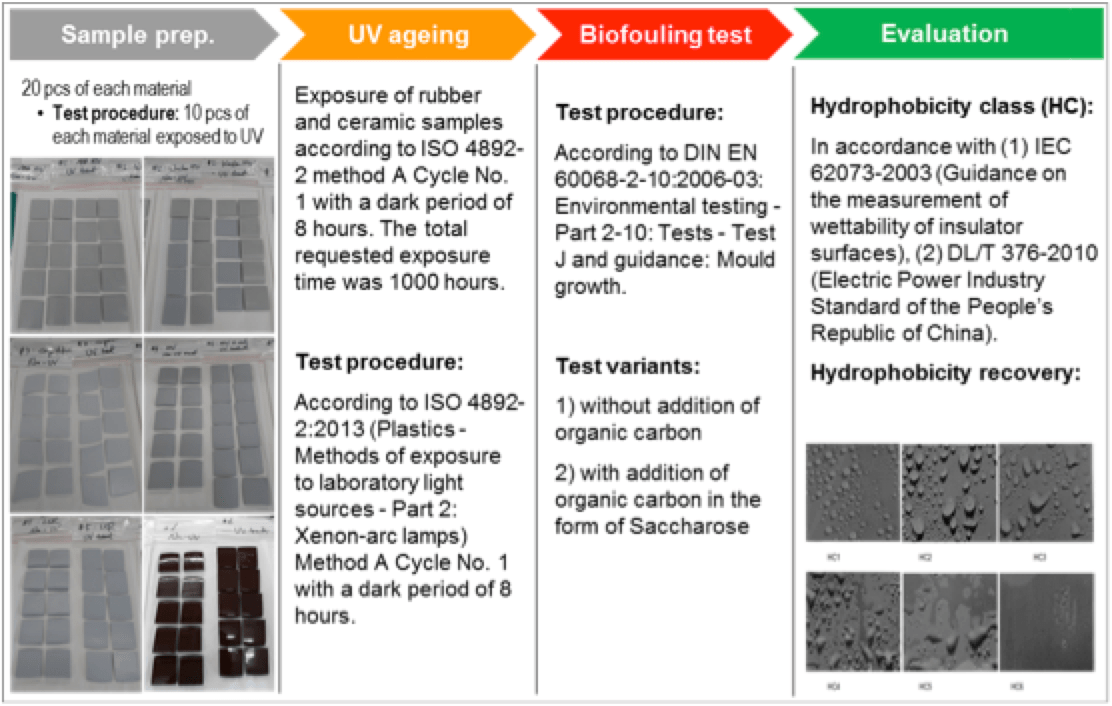

Twenty specimens with about 25 cm2 of surface area were cut from each of these 6 sample materials and cleaned with isopropanol before being rinsed with de-ionized water. After drying, specimens were placed in a dust-free container and kept under standard laboratory conditions (23°C, 50%RH) for at least 24 hours before further treatment. Fig. 1 illustrates the approach used in this research, whereby half the test specimens for each different material underwent accelerated ageing (i.e. 1000 h UV exposure) to simulate impact of weathering on insulator microstructure while the other half did not.

Accelerated Ageing: UV Exposure

The UV exposure test of the 6 different materials was carried according to ISO 4892-2:2013 Method A Cycle No. 1 with a dark period of 8 hours. Total exposure time was 1000 hours.

Biological Test: Mold Growth, DIN EN 60068-2-10

This testing, performed according to DIN EN 60068-2-10:2006-03, saw the surface of test specimens inoculated with a suspension of 9 different types of mold fungi having a concentration of 1.0 x 106 spores/ml). Specimens were then incubated under optimal conditions for development of fungi, i.e. 28±2°C and relative humidity of 95±4%. Two variations of the test were conducted: in the case of the UV ageing, 5 pcs were tested with addition of saccharose and 5 pcs without. Surface infestation was evaluated by visual examination after two weeks and 4 weeks.

Hydrophobicity Classification Test

After the biological testing, hydrophobicity class was determined by inclining sample surfaces 25° with respect to the plane surface and continuously spraying with de-ionized water for 25 seconds. Immediately afterwards, hydrophobicity class, HC, was determined according to IEC 62073-2003 (Guidance on the measurement of wettability of insulator surfaces) as well as DL/T 810-2002 (Electric Power Industry Standard of the People’s Republic of China – Technical Specification for ±500 kV D.C. Long Rod Composite Insulators). An HC of 1 or 2 corresponds to a hydrophobic surface and an HC of 6 to 7 is deemed a hydrophilic surface. After determining HC, the so-called biofilm, i.e. fungi covering the insulator surface were removed using tissue damped with isopropanol and rinsed with de-ionized water. Specimens were placed in a dust-free container and kept under standard laboratory conditions (23°C, 50%RH) for 48 consecutive hours before HC was determined again using the methods described.

Research Results

Unaged Insulation Materials

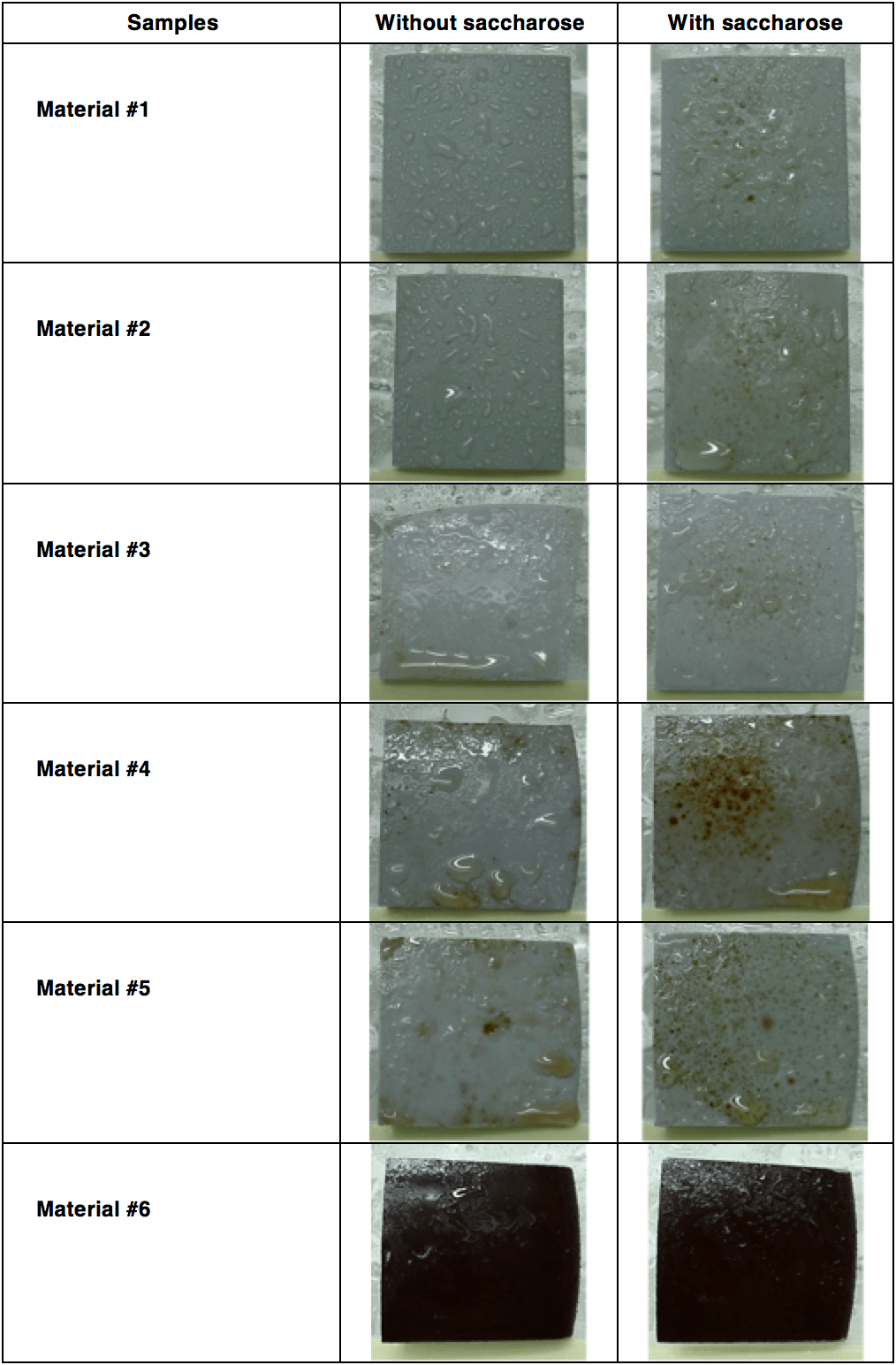

All materials tested were infested by mold fungi, but when an external carbon source was available, i.e. by adding saccharose, infestation was heavier in each case. Materials #1, #2 and #5 showed the lowest level of mold growth whereas extensive infestation was observed on surfaces of materials #3, #4 and also the porcelain (#6).

UV-Aged Insulation Materials

All these test specimens were infested by mold fungi over their entire surfaces, with infestation visible to the naked eye after two weeks. Addition of saccharose typically led to a heavier infestation. All test specimens reached the highest rating in the classification system used, i.e. mold infestation covering more than 25% of the surface and visible to the naked eye.

Hydrophobicity Classification (HC)

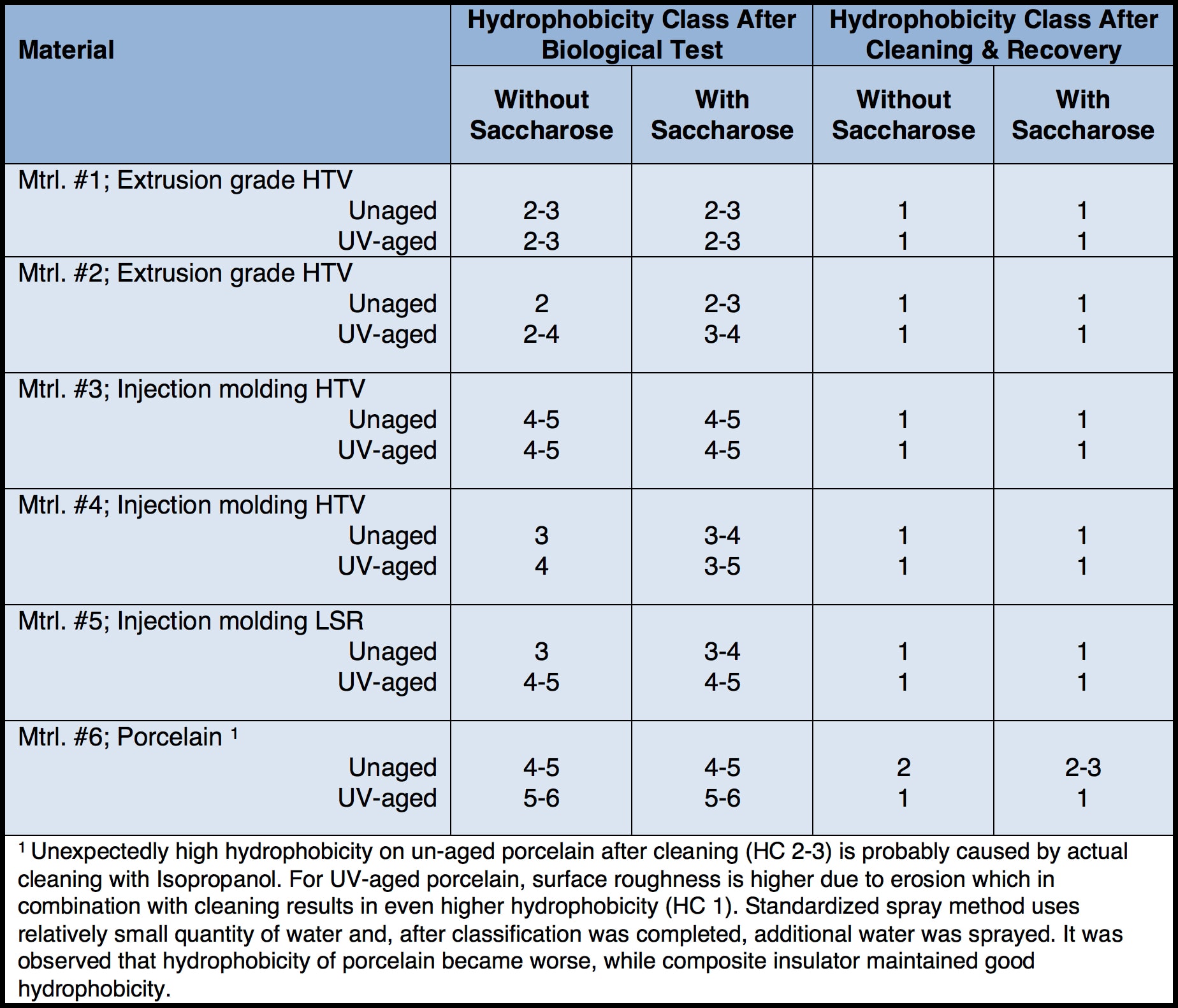

Table 2 shows the HC values determined and Fig. 2 provides typical images of surfaces during the evaluation. Results corresponded with observed rating results in the fungal test, i.e. surfaces covered with more fungi were more hydrophilic. Moreover, hydrophobicity decreased with UV weathering/ageing and also when tested with an external carbon source. Materials #1 and #2 retained the highest hydrophobicity compared to other materials. After determining hydrophobicity class, the biofilm covering the insulator surface was removed by cleaning with isopropanol. Specimens were then placed in a dust-free container and kept under standard laboratory conditions (23°C, 50% RH) for 48 consecutive hours before HC testing was repeated. It should be noted that stains produced on some materials, #3 and #4 in particular, could not be removed in spite of the fact that cleaning completely removed the biofilm. Table 2 gives results from determination of HC after cleaning and shows that hydrophobicity of materials was restored significantly, with the exception that the un-aged porcelain which only recovered to an HC level of 2-3.

2nd Biological Test on UV-Aged Insulation Materials

A second test was performed to better understand whether and how fast fungi again form a biofilm on insulators that had previously been infested. To promote fungal growth, only UV-aged materials were considered this time and the test was performed only with added organic carbon in the form of saccharose. Compared to the first test, HC levels of all HTV silicone materials were either similar or had improved somewhat. However, HC levels of the LSR and porcelain insulator materials were significantly better, i.e. from HC of 4 to 5 to HC 1 to 2 and from HC 5-6 to HC 1-2, respectively. The reason for this improved hydrophobicity is not clear and may requires further investigation.

Summary & Conclusions

Biofilms can readily form on HV outdoor insulation, both ceramic and polymeric, with most cases reported in tropical environments. Biofilm formation occurred predominantly in areas of the insulator that are shaded from direct sunlight, indicating that partial shade was necessary to prevent desiccation. Insulator geometry therefore also influences extent of biofilm formation. The most commonly reported impact of the biofilm is reduction in hydrophobicity, which reduces wet flashover voltage. Reduction in wet flashover voltage was typically much higher for ceramic insulators (up to about 70%) than for polymeric insulators (up to only about 30%).

In general, it has been reported that silicone rubber is highly resistant to corrosion induced by microorganisms and that biofilms can be effectively removed by a combination of washing and wiping. Biofilms can also contain organisms that produce pigments and cause discoloration. For example, pigments produced by certain fungal species are known for easily defusing into lipophilic polymers, such as silicone rubber and therefore discoloration is not removed by cleaning. These problems are mostly aesthetic and do not affect insulator performance. In regard to experience with silicone rubber, some publications reported that amount of biofilm formation varied among different types of silicone insulators and extent of growth depended on rubber formulation. However, since insulators were of different design, relative impact of shed geometry in each case cannot be excluded. Comparing different silicone rubber test plates in a controlled laboratory environment, amount of biofilm formation differed among formulations. It may be that different degree of biofilm formation is due to variations in fillers or other additives or it can simply be a result of differences in surface roughness.

To gain greater insight, 5 types of silicone rubber as well as a ceramic reference material were all exposed to a biological test, either when virgin or after 1000h UV ageing. All silicone rubber materials were initially fully hydrophobic (HC 1) whereas virgin porcelain was less hydrophobic (HC 2-3). Testing showed that all virgin materials supported biological growth to various degrees and addition of an external nutrition source, such as saccharose, increased amount of biofilm. Extrusion grade HTV silicones exhibited lower biofilm coverage and superior hydrophobicity (HC 2-3) compared to injection molded LSR and porcelain, which were slightly less hydrophobic (HC 3-5). UV-aged materials exhibited higher coverage of biofilm compared to corresponding virgin samples. It is difficult to link difference in biofilm formation to specific silicone properties since these materials differ in composition, hardness and surface structure.

Test samples were then cleaned using a tissue moistened with isopropanol. After cleaning, hydrophobicity was restored for all samples (silicones: HC 1, porcelain: HC 1-3). UV-aged samples were again sent for biological testing with an external nutrient present. All samples supported biological growth, however coverage was reduced for all materials. This was also reflected in higher hydrophobicity (HC 1 to 4). It could therefore be concluded that re-colonization was slower after cleaning silicone and porcelain surfaces. This corresponds with reported service experience, e.g. no major re-colonization could be found when silicone insulators were inspected 8 years after removing biofilms with ethanol.

References

An overview of existing literature dealing with biological growth on outdoor insulation for HV electrical applications has been conducted as part of the project (1). The experimental part has been conducted in cooperation with accredited laboratories in Europe (2).

(1) Henrik Hillborg, “Biofouling on silicone rubber outdoor insulation”, Internal ABB document 2016/SECRC/P/TN/311.

(2) Sung-Woo Cho, and Henrik Hillborg, “Biofouling on silicone rubber outdoor insulation”, Internal ABB document, 2018/SECRC/T/TR/95.