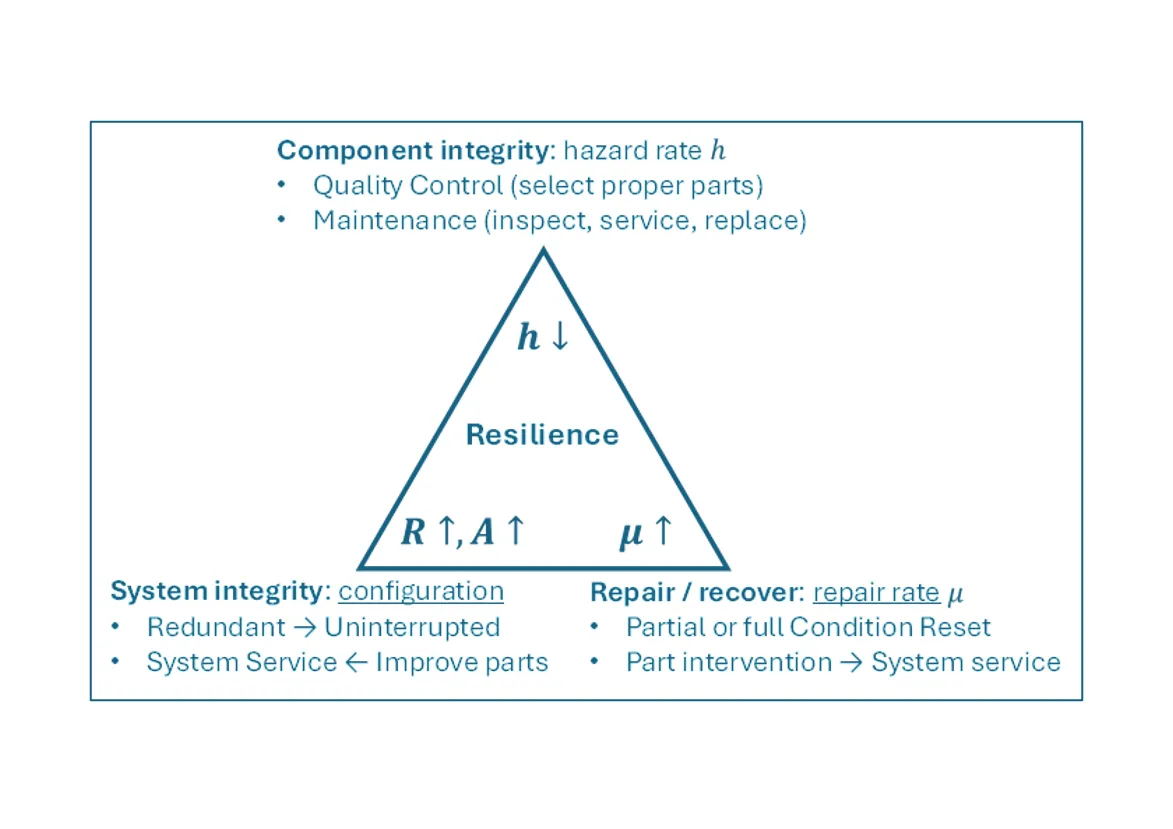

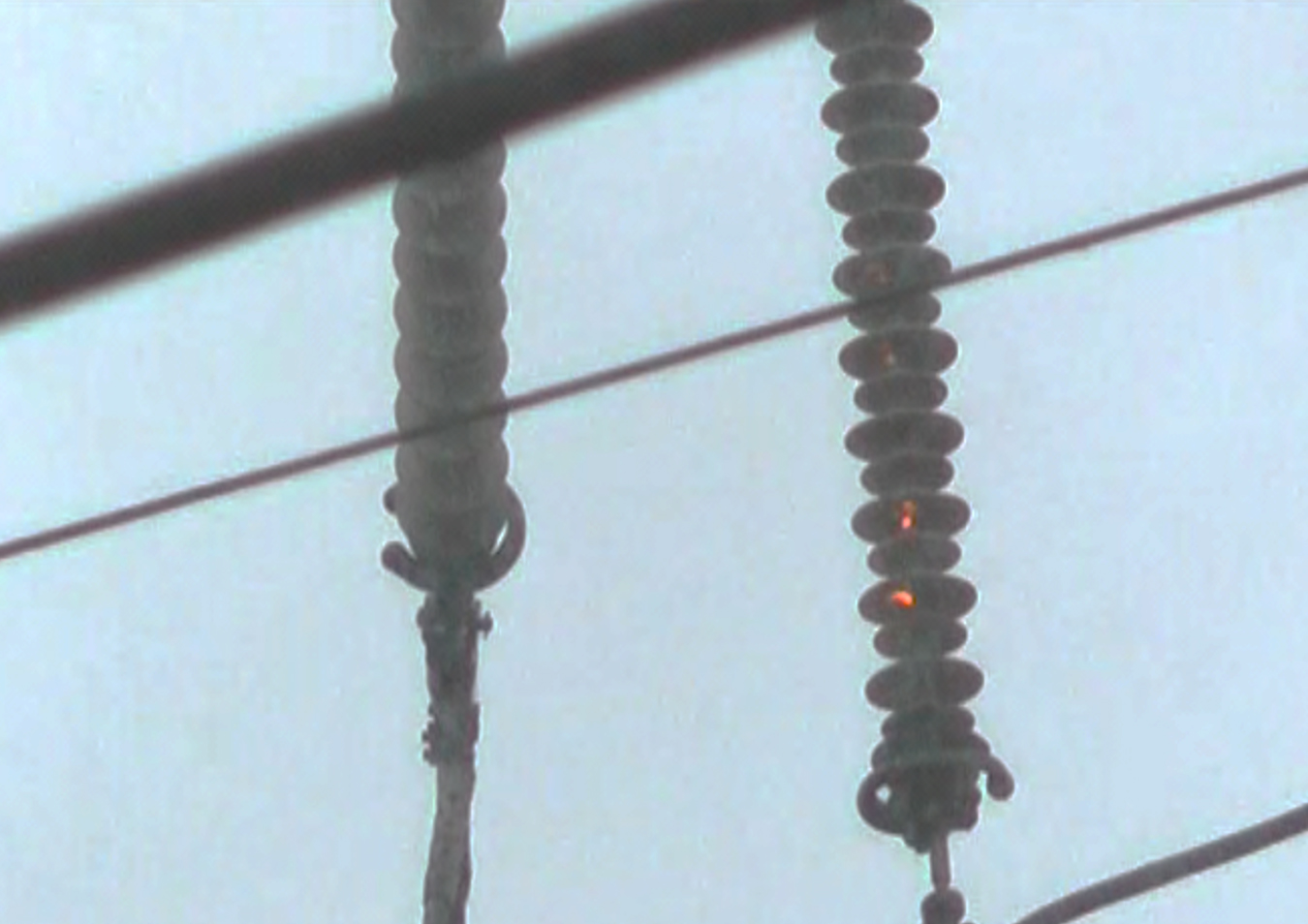

Among the challenges faced by electricity supply utilities is reaching expected reliability targets with ageing equipment that operates at high utilization levels while often also exposed to severe environments. Unfortunately, the huge asset value of electrical infrastructure (in the U.S. estimated to exceed $800 billion) means that existing grid components cannot simply be changed out with new technologies. Rather, the focus must be on gradually replacing assets that have reached the end of their normal operating life. This makes it crucial to develop and install technologies that can assess condition of components and provide decision tools to help prioritize maintenance and/or replacement. Sensors are among the technologies that enable such decision-making. This edited contribution to INMR by Andrew Phillips, V.P. of T&D at EPRI, discussed various value streams for sensor technologies and presented an overview of EPRI’s RF Sensor Suite. It also offered examples of the opportunities sensor deployment can offer to facilitate grid modernization.

>

Value Streams

Sensors offer numerous opportunities to provide added value for a transmission system. Examples include:

Safety & Reliability

Knowledge of whether an asset is at imminent risk of failure enables actions to be taken to better address safety.

Workforce Deployment

Improved planning for personnel to be deployed to deal with either an imminent outage or possibly to prevent an outage.

Condition-Based Maintenance

Maintenance actions can be initiated at the most appropriate time, increasing cost effectiveness.

Asset Management

Sensors enable improved allocation of resources for asset management since their data supplements similar vintage performance information, failure databases and operational data.

Increased Asset Utilization

Sensors allow improved dynamic ratings to be achieved through precise, real time knowledge of the actual condition of grid components.

Forensic & Diagnostic Analysis

Sensors offer investigators better information to identify root causes of failures.

Increased Operator Awareness

Sensors can assist operators to make more informed decisions in regard to those components that are at high risk.

RF Sensor Suite Activities

Sensor Types

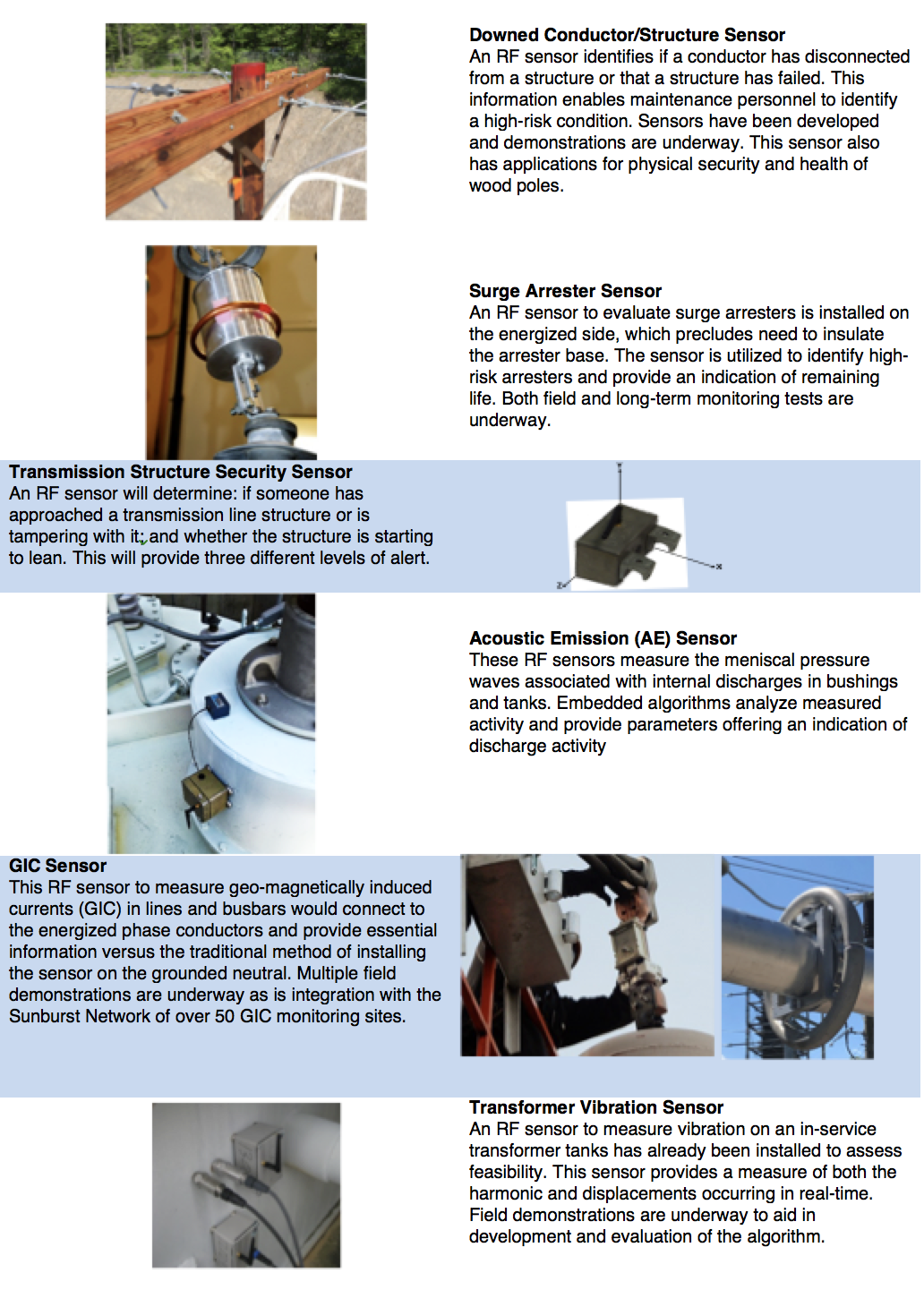

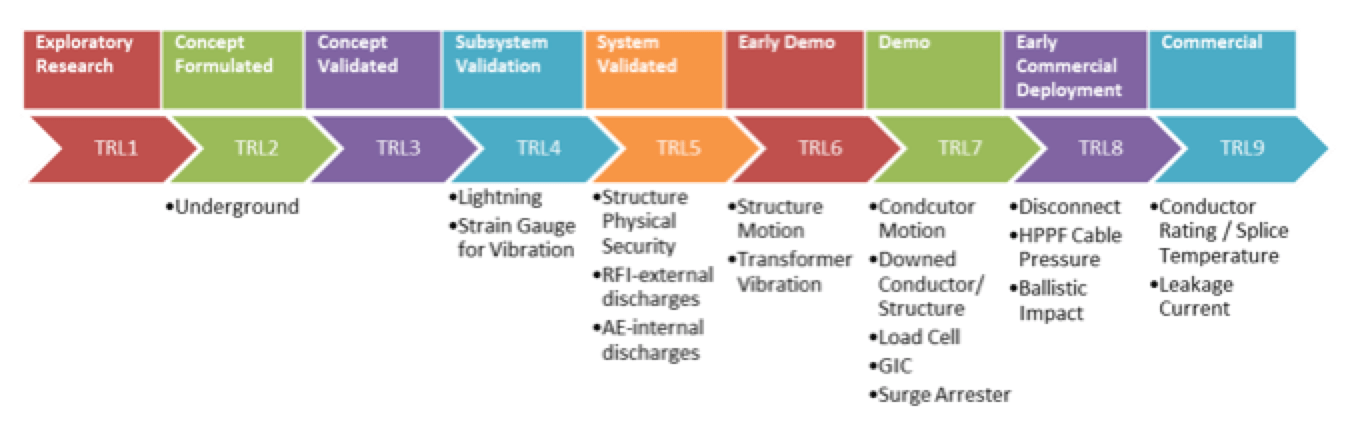

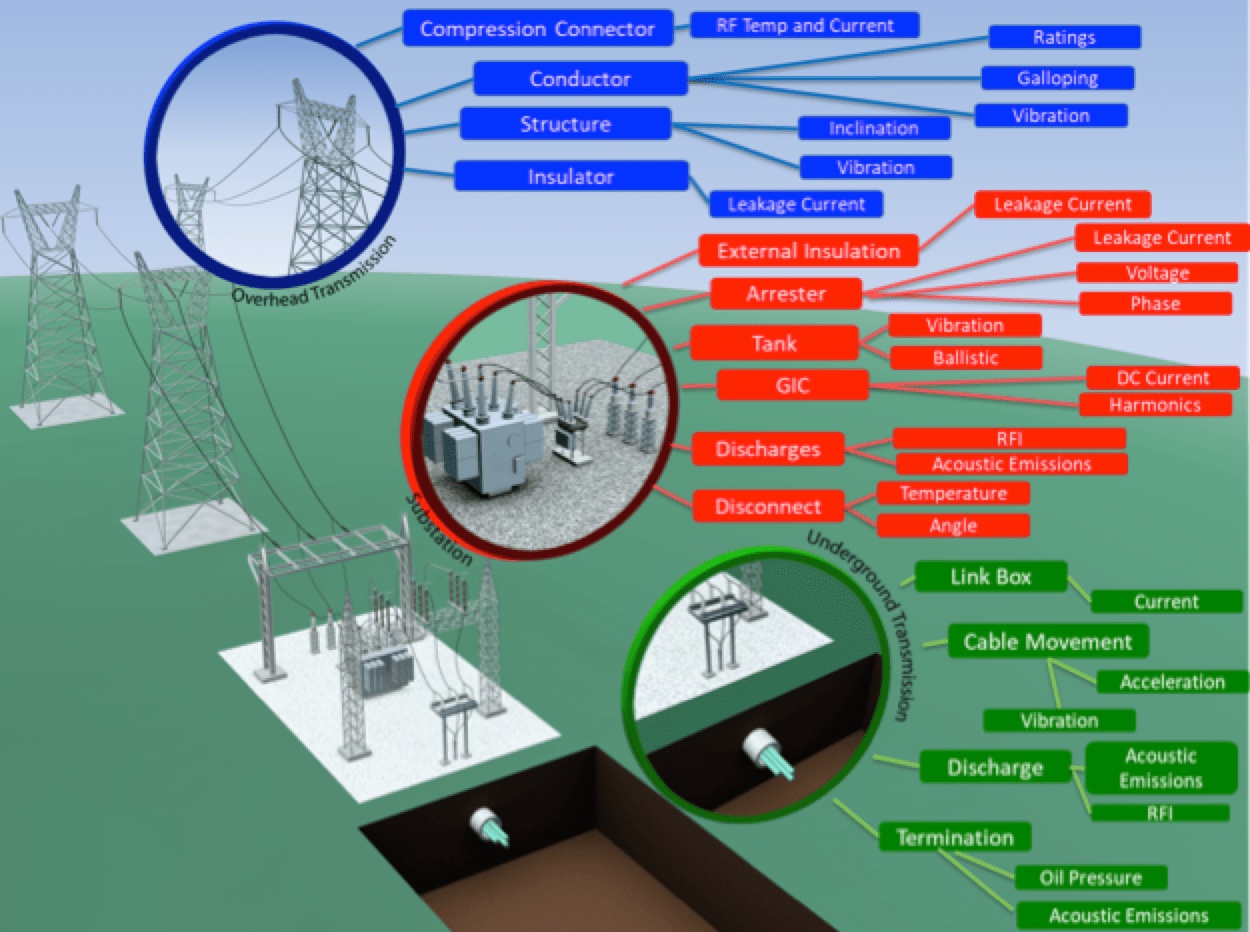

As shown in Fig. 1, sensors for different types of assets are in continual development.

Sensing Element

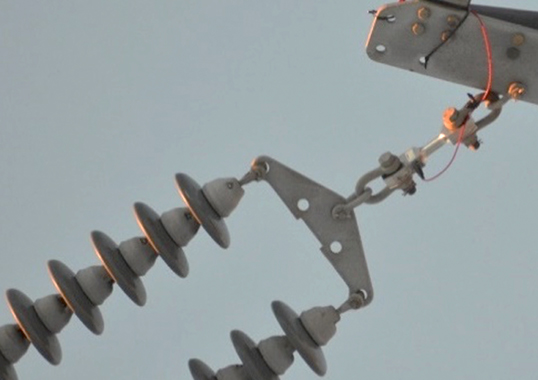

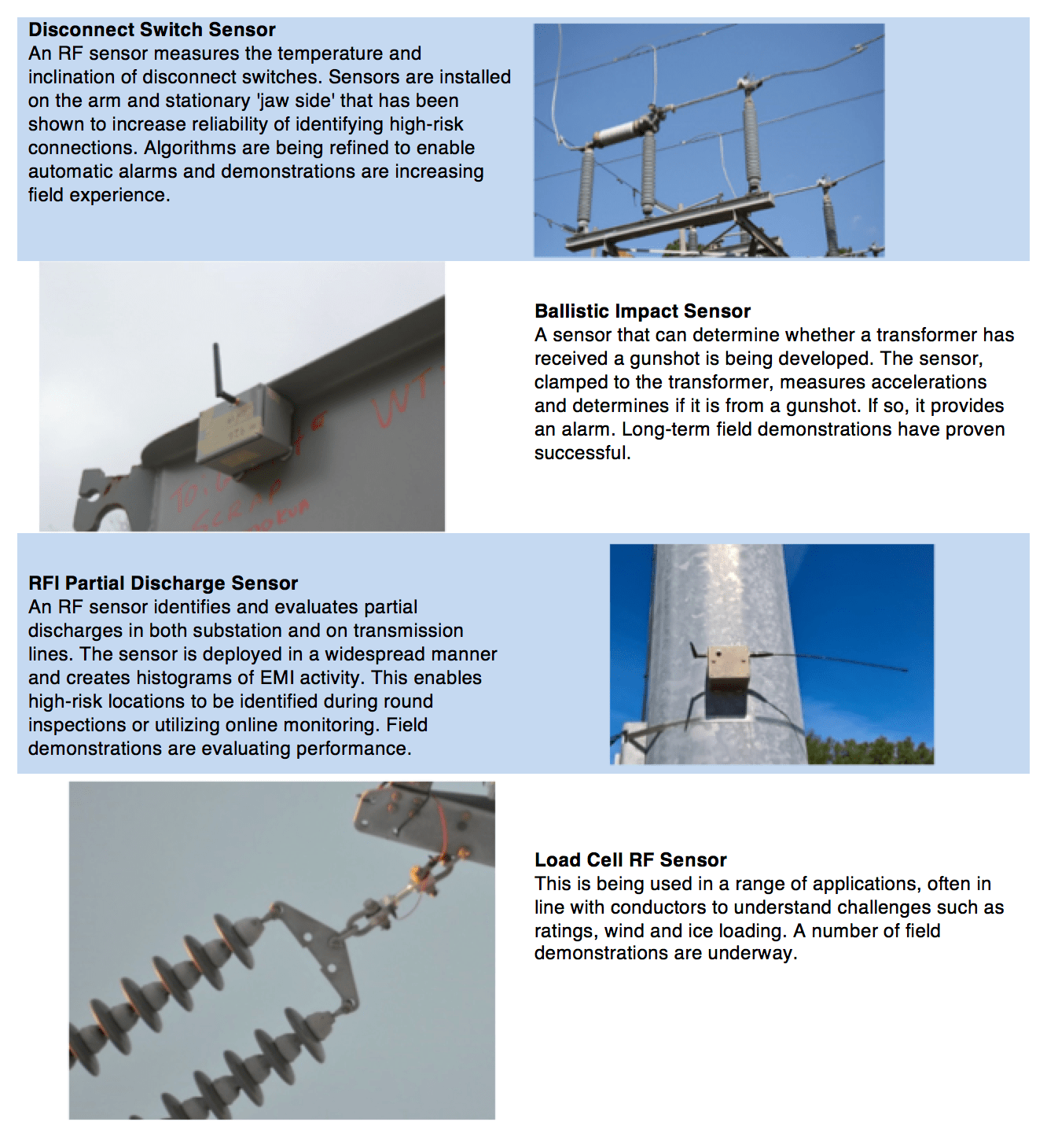

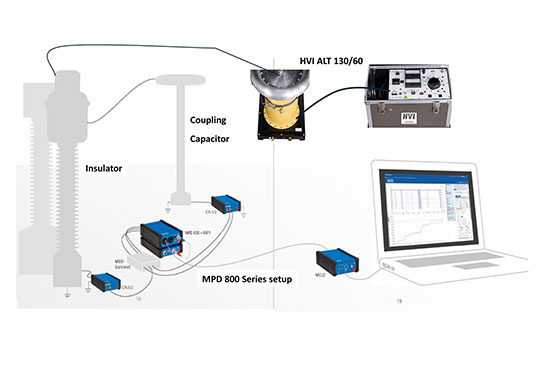

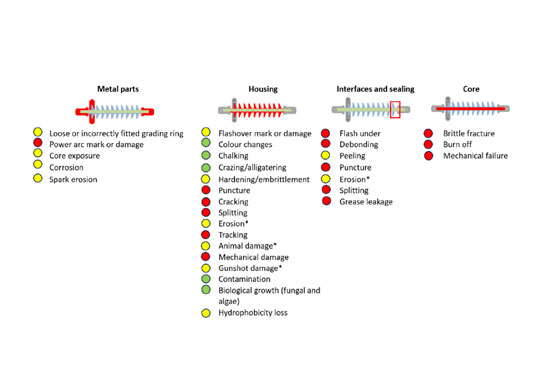

Elements that measure the appropriate parameters are essential and a first step in determining these parameters is to understand the degradation and failure modes of assets being assessed. Fig. 2, for example, illustrates components addressed by EPRI’s RF Sensor Suite.

Power Harvesting & Storage

Providing power to the sensor is often a challenge. In the case of the RF Sensor Suite, power harvesting and storage technologies with lifetime greater than a decade are available for each sensor application.

Sensor Mechanical Design & Packaging

Each RF Sensor Type has been designed for the specific application at hand accounting for electrical, mechanical and environmental stresses. Where needed, packaging also facilitates installation under energized conditions.

Communication

The last link between sensor and utility communication infrastructure is often a challenge. For this reason, the RF Sensor Suite has developed 2 RF communication architectures that enable all sensor types to be integrated. A 3rd form of communication is in development. Choice of RF approach will depend on application.

Algorithms, Alerts & Alarms

Embedded algorithms and associated analytics have already been developed and are still being researched to convert measured data into information and action.

Data Integration & Visualization

Two approaches have been developed: 1. Integrating RF Sensors into the utility information and communication infrastructure; and 2. EPRI hosted secure service. Either can be applied depending on experience and structure of utility.

Advanced Analytics

EPRI employs world-class experts associated with each asset type. An additional team has also been formed to provide advanced analytics tools and support.

Actions Required

Fully realizing the benefits of tools such as the RF Sensor Suite requires the following actions:

Accelerated Individual RF Sensor Development

As shown in Fig. 1, multiple RF sensors types are in various stages of development, demonstration or commercialization. Acceleration of earlier technology readiness level (TRL) of RF Sensors is required to move them closer to full-scale industry adoption.

Short & Long-Term Testing

A vital part of sensor development and production is having test facilities and protocols to verify sensor performance and to assess long-term performance.

Field Demonstrations

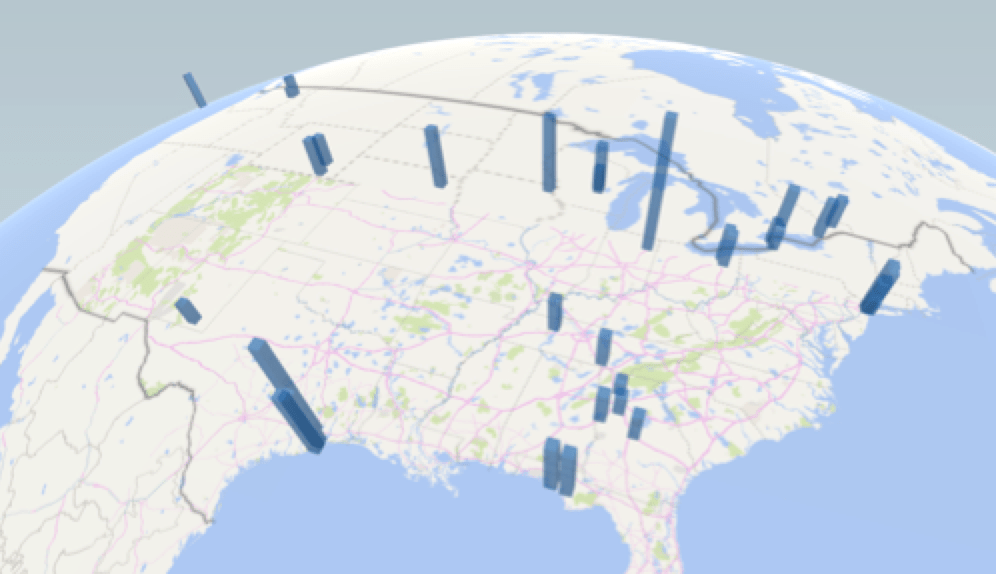

Multiple field demonstrations are underway in different environments and applications. Increasing the number of simultaneous such demonstrations will result in 10s of years of ‘sensor hours’ to be gained in only a few years, thereby increasing acceptance by utility staff.

Commercialization

A well-defined path for commercialization is vital. Some types of sensors are already commercially available from EPRI. Accelerating deployment of available sensors will advance the knowledge needed to best extract value from the data generated.

Opportunity

EPRI

A suite of RF sensors at various stages of TRL are presently in the pipeline supported by EPRI experts and input from more than 20 utilities. This effort has been underway for over a decade. Ongoing development and refinement is needed, even for the most mature sensor, since technology changes, needs differ and new lessons are always being learned. A total of 22 EPRI member utilities are currently extracting value from the RF Sensor Suite and enabling field demonstrations and large deployment of early commercial units.

Sensors in Development and/or Demonstration

Further Reading

Staying in Shape: Advanced Sensor Technologies Can Help Keep Aging Transmission and Distribution Systems in Good Condition, IEEE Power and Energy, Vol.8, No.2 March/April 2010

Sensor Technologies for a Smart Transmission System, 1020619, EPRI, 2009