Maximizing and Validating Ultimate Capacity in High Strength Applications by Ed Niedospial

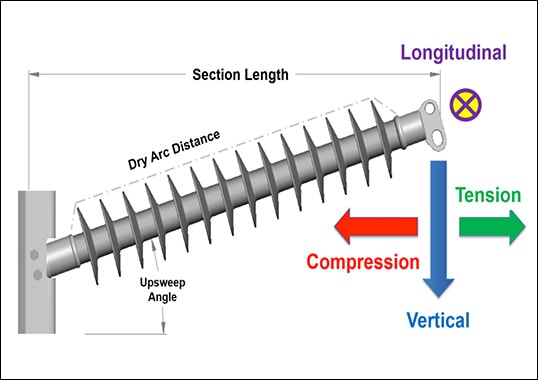

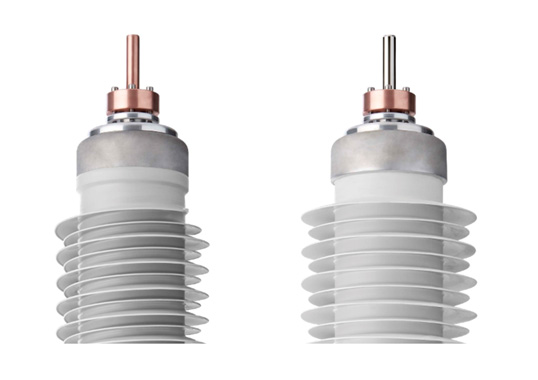

High strength insulators can improve efficiency of a project, which can then be measured in shorter project duration and also lower total cost. But gaining such added efficiency is a function of going beyond what has typically been done and finding new solutions. The challenge is to demonstrate that the new solutions will work. Mechanical loading of suspension insulators is comparatively simple since both specified mechanical load (SML) and rated tensile load (RTL) are both easily understood and quantifiable. Regardless of application, the primary load applied to the insulator is tensile and for any SML an insulator is not limited by section length. Maximizing tensile performance of a suspension insulator is a function of increasing the rod diameter, upgrading end fittings and getting the most tensile output from the crimping process. Where 30klb and 50klb have typically been the most used ultimate strengths for polymeric insulators, suspension applications can now go to 120klb SML and beyond, if required. This presentation discusses how current insulator applications can be improved for higher mechanical capabilities and how these can be tested and validated.